Rotational motor

A technology for rotating motors and rotors, applied in the field of rotating electric motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

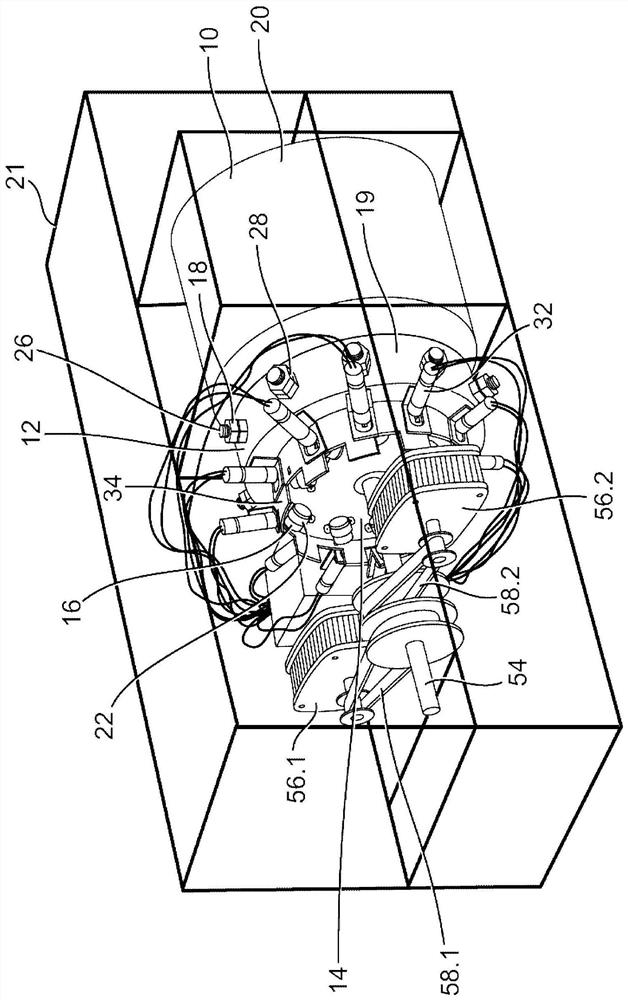

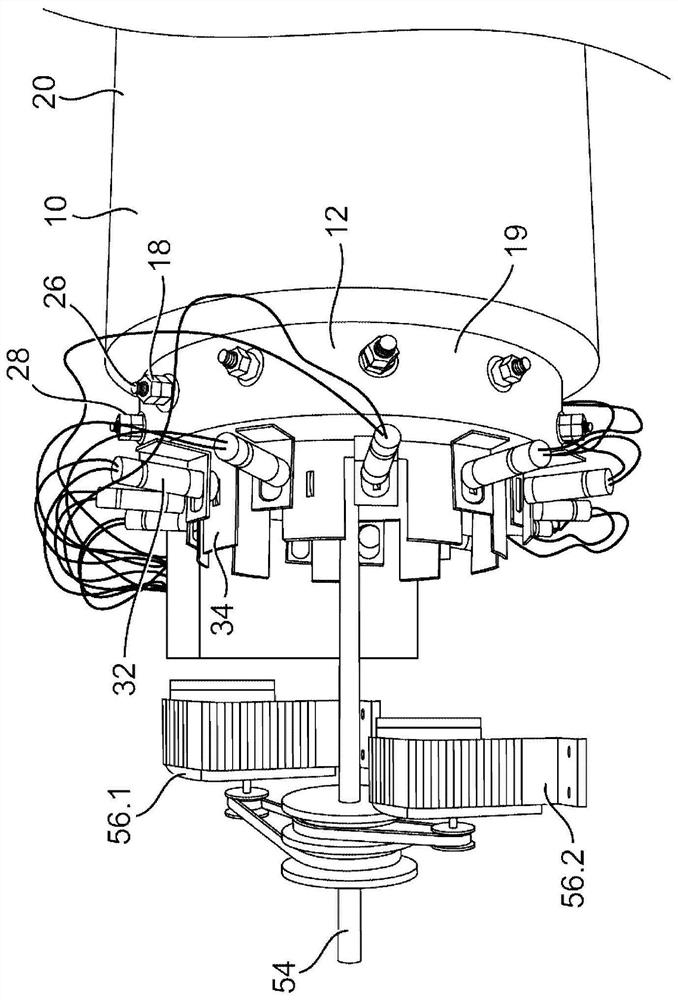

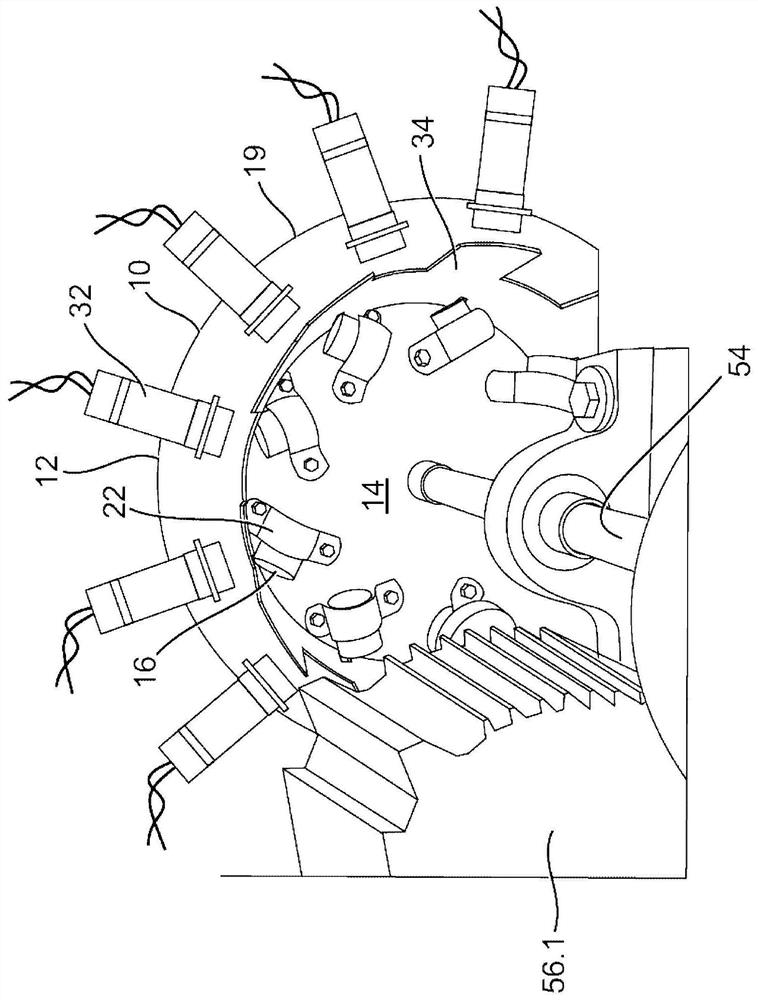

[0043] refer to figure 1 , an example embodiment of the present invention provides a rotary motor 10 comprising a stator 12 and a rotor 14 and at least two magnets including a permanent magnet 16 and an electromagnet 18, wherein one of the magnets is attached Connected to the stator 12 , one of the magnets is attached to the rotor 14 . The magnets 16, 18 are arranged relative to each other such that when the electromagnet 18 is switched off, the permanent magnet 16 is attracted by the ferromagnetic core towards the electromagnet 18 causing the rotor 14 to rotate relative to the stator 12, and when the electromagnet 18 is switched on , the permanent magnet 16 is repelled by the electromagnet 18 , causing the rotor 14 to continue to rotate relative to the stator 12 .

[0044] More specifically, in the example depicted, the stator 12 includes a cylindrical housing 19 provided at one end of a motor block 20 of the rotary motor 10 . The engine block 20 is immovably fixed within a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com