Production process of soybean milk rich in natural dietary fiber without additives and processing aids

A processing aid, additive-free technology, applied in the fields of food science, food heat treatment, food homogenization, etc., can solve the problems of insufficient removal of beany odor, affecting the taste of soy milk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

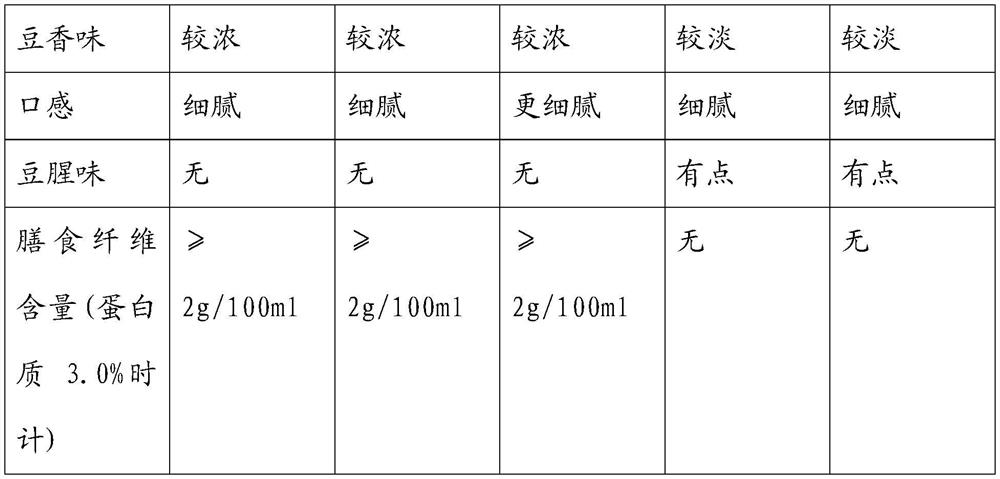

Embodiment 1

[0039] Bean sifting: use non-GMO soybeans in the current season, and soybeans with complete grains after impurity removal and color selection.

[0040] Soybean soaking: use the traditional soaking process, the preferred water temperature for soaking beans is 20°C, and the soaking time is 6 hours.

[0041] Whole bean enzyme deactivation: the whole bean enzyme deactivation is to deactivate enzyme in an enzyme deactivation machine, the temperature is 93°C, and the deactivation time is 25 minutes;

[0042] Wet bean peeling: the peeling rate is required to be greater than or equal to 90%.

[0043] Coarse grinding of soybeans; the temperature of the refining water is 80°C.

[0044] Soybean fine grinding: After coarse grinding, soybean milk passes through a high-speed rotating cutter head to further refine the fiber.

[0045] The first homogenization; the homogenization temperature is 60°C, and the homogenization pressure is 40MPa.

[0046] The second homogenization; the homogeniz...

Embodiment 2

[0053] Bean sifting: use non-GMO soybeans in the current season, and soybeans with complete grains after impurity removal and color selection.

[0054] Soybean soaking: use the traditional soaking process, the preferred water temperature for soaking beans is 20°C, and the soaking time is 6 hours.

[0055] Whole bean enzyme deactivation: the whole bean enzyme deactivation is carried out in an enzyme deactivation machine at a temperature of 93-97° C. and an enzyme deactivation time of 20-25 minutes.

[0056] The peeling rate of wet beans is greater than or equal to 95%.

[0057] Coarse grinding of soybeans; the refining water temperature is required to be 85°C.

[0058] Soybean fine grinding: After coarse grinding, soybean milk passes through a high-speed rotating cutter head.

[0059] The first homogenization; the homogenization temperature is 70°C, and the homogenization pressure is 50MPa.

[0060] The second homogenization; the homogenization temperature is 65°C, and the h...

Embodiment 3

[0068] Bean sifting: use non-GMO soybeans in the current season, and soybeans with complete grains after impurity removal and color selection.

[0069] Soybean soaking: use the traditional soaking process, the preferred water temperature for soaking beans is 20°C, and the soaking time is 10 hours.

[0070] Enzyme inactivation of whole beans: the inactivation of enzymes in whole beans is carried out in an enzyme inactivator at a temperature of 96° C. and an inactivation time of 24 minutes.

[0071] Wet bean peeling: the peeling rate is required to be greater than or equal to 95%.

[0072] Coarse grinding of soybeans; the refining water temperature is required to be 90°C.

[0073] Soybean fine grinding: After coarse grinding, soybean milk passes through a high-speed rotating cutter head.

[0074] The first homogenization; the homogenization temperature is 70°C, and the homogenization pressure is 70MPa.

[0075] The second homogenization; the homogenization temperature is 70°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com