Production process of viable bacterium plant yoghurt preserved at normal temperature

A technology of room temperature storage and production technology, applied in the direction of lactobacillus, food science, bifidobacteria, etc., can solve problems such as sticky taste and complex preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

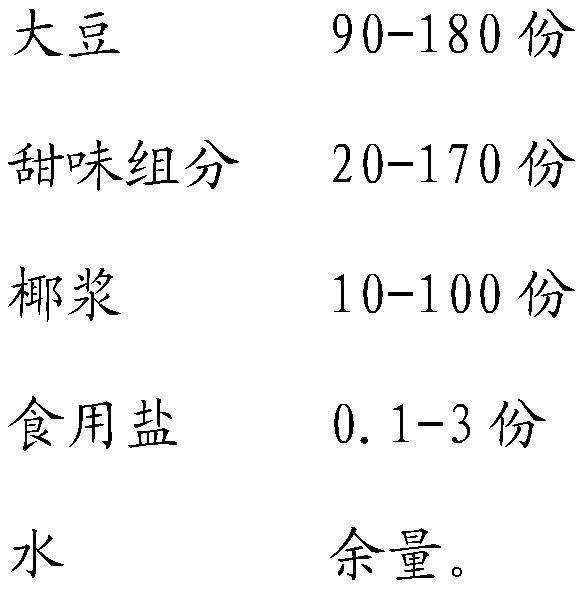

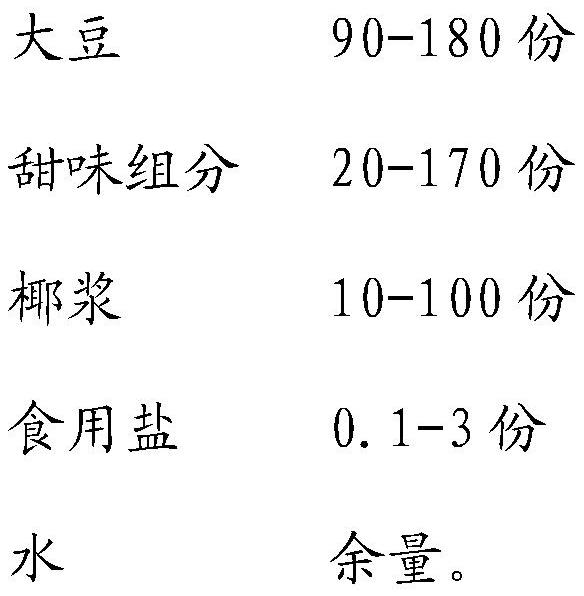

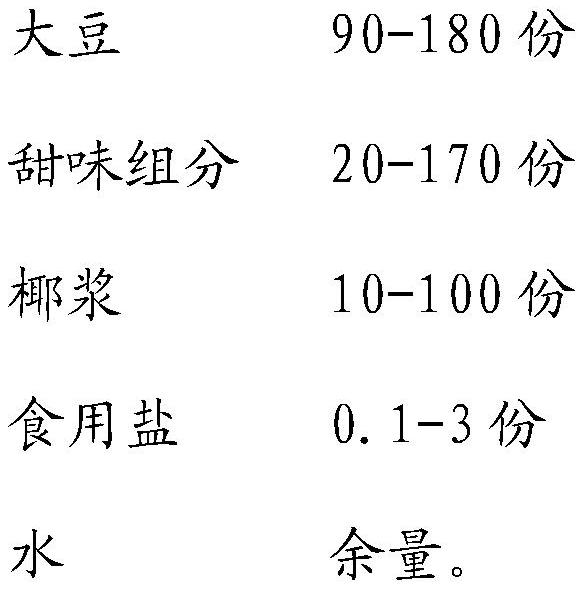

[0030] Total raw material is based on 1000 parts by weight (containing sucrose formula):

[0031] 120 servings of soybeans

[0032] Sweetness component (select white granulated sugar) 45 parts

[0033] Coconut milk 10 parts

[0034] Edible salt 0.1 parts

[0035] water balance.

[0036] Soybean screening: select non-GMO soybeans in the current season, and select soybeans with complete grains after impurity removal and color selection.

[0037] Soybean soaking: The traditional soaking process is adopted, the preferred water temperature for soaking beans is 25°C, and the soaking time is 6 hours.

[0038] Whole bean enzyme inactivation: the whole bean enzyme inactivation is carried out in an enzyme inactivator at a temperature of 94° C. and an enzyme inactivation time of 20-25 minutes.

[0039] Wet bean peeling: The peeling rate of wet beans is required to be greater than or equal to 95%. A low peeling rate will have a greater impact on the taste of the entire product, and a...

Embodiment 2

[0057]Total raw material is based on 1000 parts by weight (no sucrose formula):

[0058] soybeans 120

[0059] Coconut milk 60 parts

[0060] Erythritol 47

[0061] Stevioside 0.07

[0062] Sucralose 0.06

[0063] Edible salt 0.16

[0064] water balance

[0065] Soybean screening: select non-GMO soybeans in the current season, and soybeans with complete grains after impurity removal and color selection.

[0066] Soybean soaking: The traditional soaking process is adopted, the preferred water temperature for soaking beans is 25°C, and the soaking time is 6 hours.

[0067] Whole bean enzyme inactivation: the whole bean enzyme inactivation is at 96°C in an enzyme inactivator, and the inactivation time is 23 minutes.

[0068] Wet bean peeling: The peeling rate is required to be greater than or equal to 95%. A low peeling rate will have a greater impact on the taste of the entire product, and a high peeling rate will reduce the yield of soybeans.

[0069] Coarse grinding of...

Embodiment 3

[0086] Total raw material is based on 1000 parts by weight (containing sucrose):

[0087] 140 servings of soybeans

[0088] 45 parts white sugar

[0089] Coconut milk 50 parts

[0090] 0.5 portion of edible salt

[0091] water balance

[0092] Soybean screening: select non-GMO soybeans in the current season, and soybeans with complete grains after impurity removal and color selection.

[0093] Soybean soaking: The traditional soaking process is adopted, the preferred water temperature for soaking beans is 22°C, and the soaking time is 6 hours.

[0094] Whole bean enzyme deactivation: the whole bean enzyme deactivation is at 93°C in an enzyme deactivation machine, and the deactivation time is 25 minutes;

[0095] Wet bean peeling: The peeling rate is required to be greater than or equal to 95%. A low peeling rate will have a greater impact on the taste of the entire product, and a high peeling rate will reduce the yield of soybeans.

[0096] Coarse grinding of soybeans: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com