Perforating and adsorbing process for soft foam core body of liquid sanitary napkin

A sanitary napkin and hole adsorption technology, which is applied to absorbent pads, clothing, underwear, etc., can solve the problems of leftovers affecting the production environment, equipment damage, and affecting the quality of the absorbent core.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

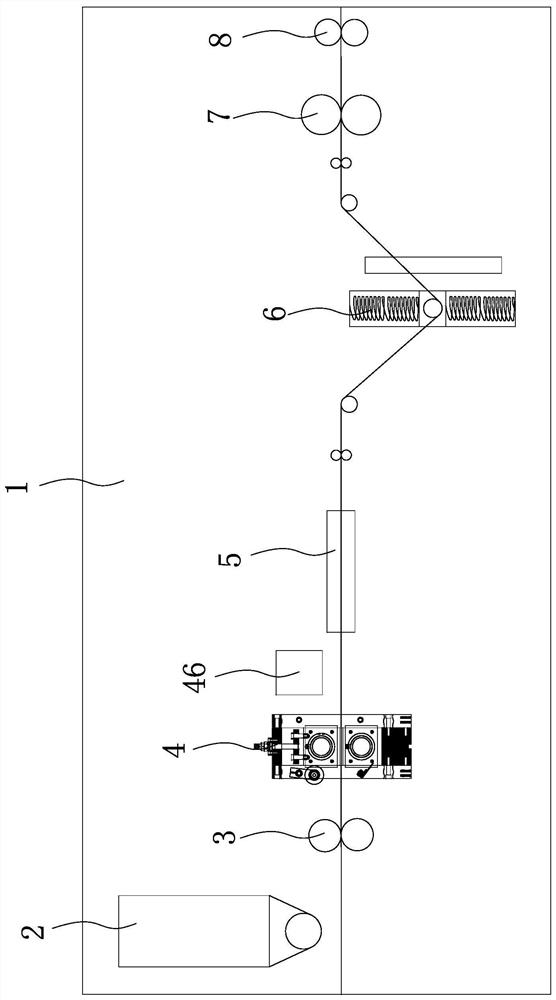

[0038] refer to Figure 1 to Figure 7 , the present embodiment provides a perforated adsorption process for a soft foam core of a liquid sanitary napkin, comprising the following steps:

[0039] (1) Manufacture of the absorbent core 10:

[0040] The driving device 7 drives the delivery of the polymer carrier material, and the unloading device 2 feeds the polymer material onto the polymer carrier material to form the absorbent core 10;

[0041] (2) Compression of the absorbent core 10:

[0042] The formed absorbent core 10 is clamped and conveyed between the first pressing roller and the second pressing roller of the pressing device 3, and the absorbent core 10 is pressed into a flat state;

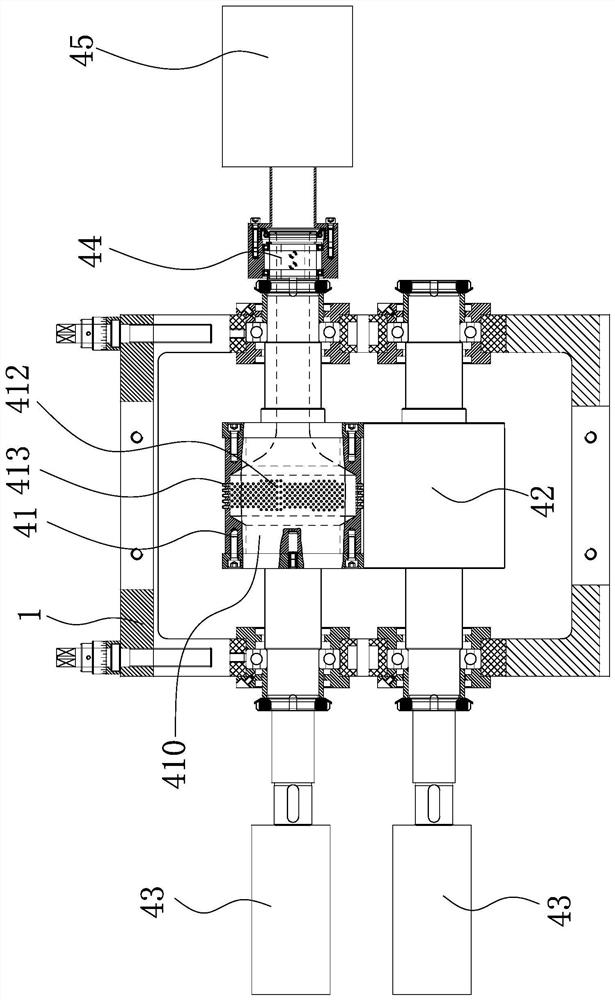

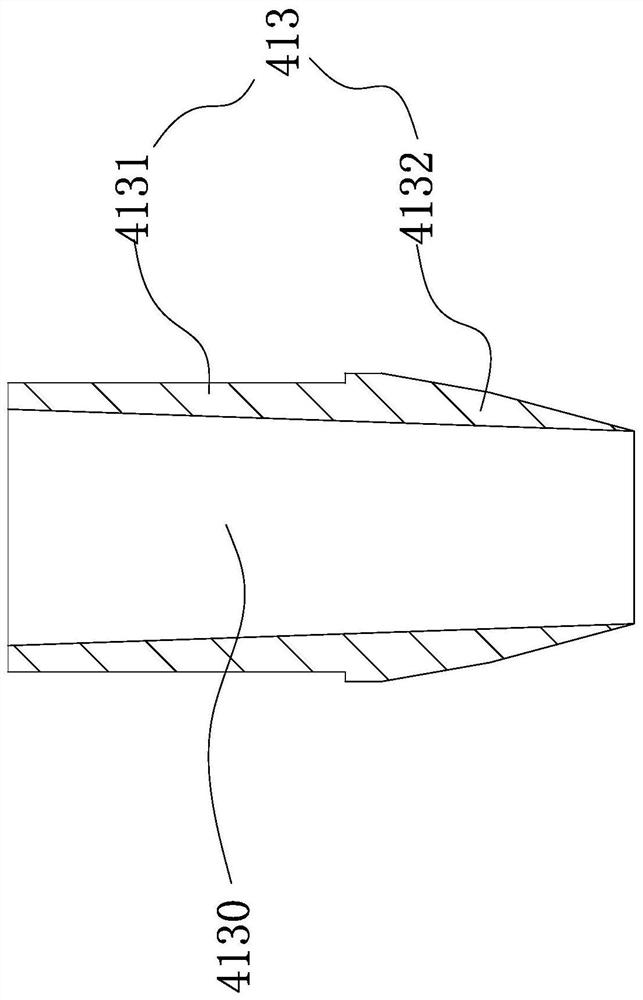

[0043] (3) Perforation of the absorbent core 10:

[0044]The absorbent core 10 is clamped and transported between the first rotating roller 41 and the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com