Oncology medicine smashing device based on high-frequency vibration

A high-frequency vibration and pulverizing device technology, applied in grain processing and other directions, can solve the problems of inability to grind medicine, inability to evenly pulverize traditional Chinese medicine, and uneven particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

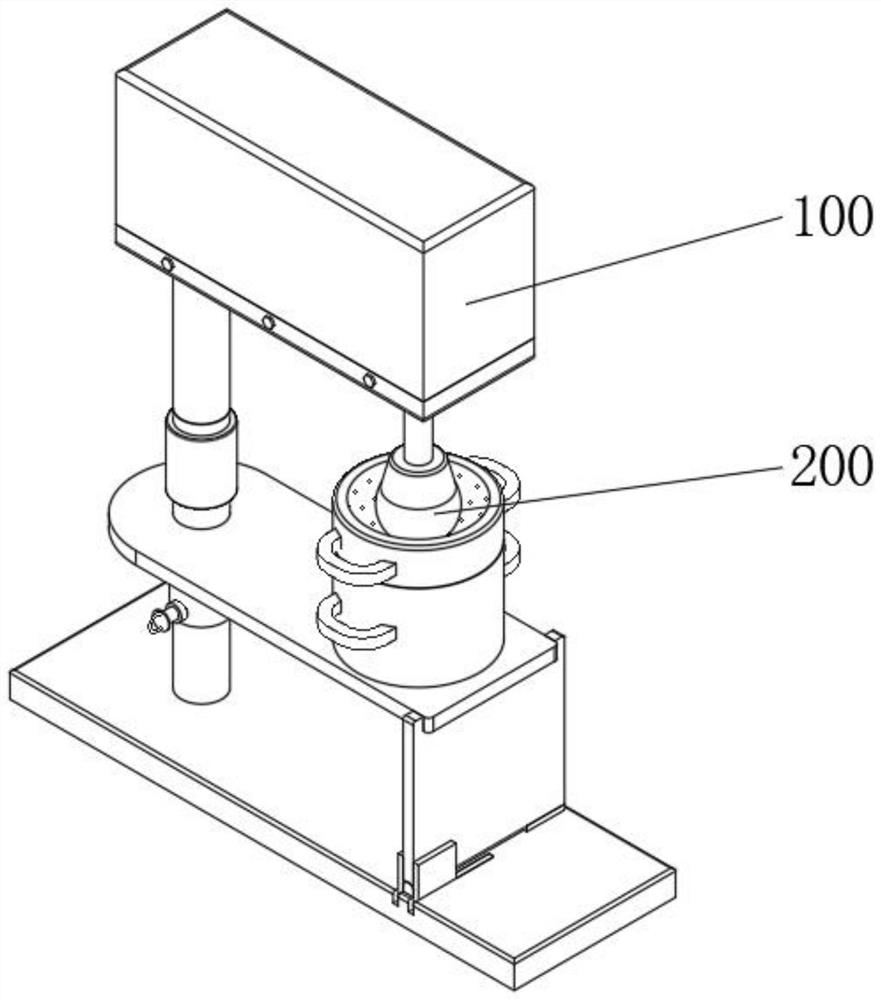

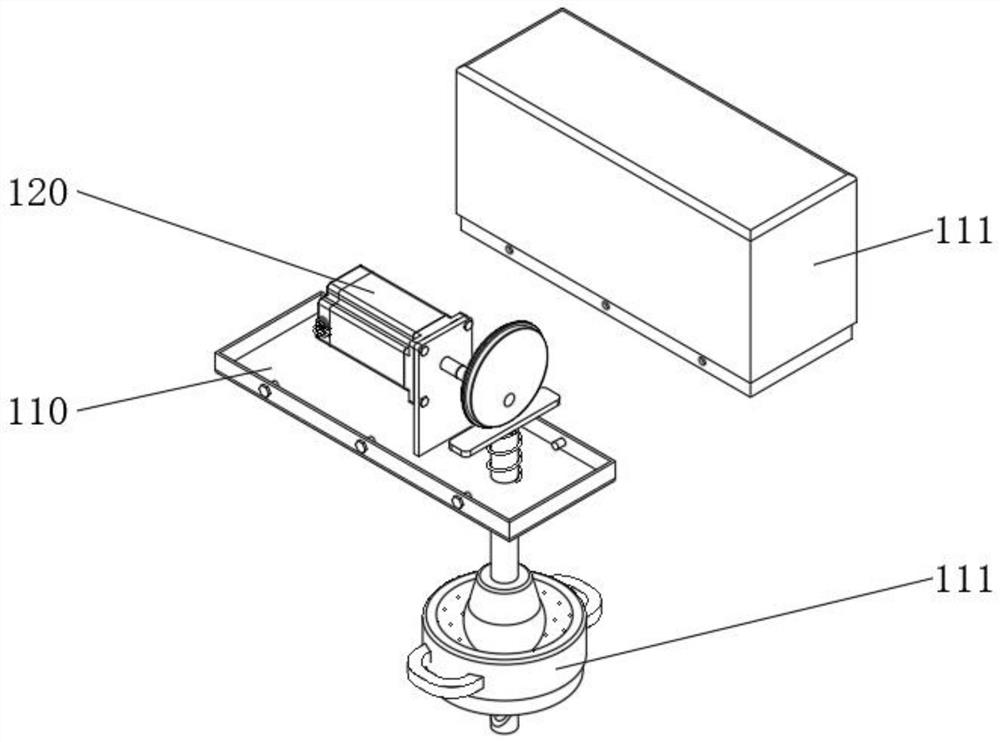

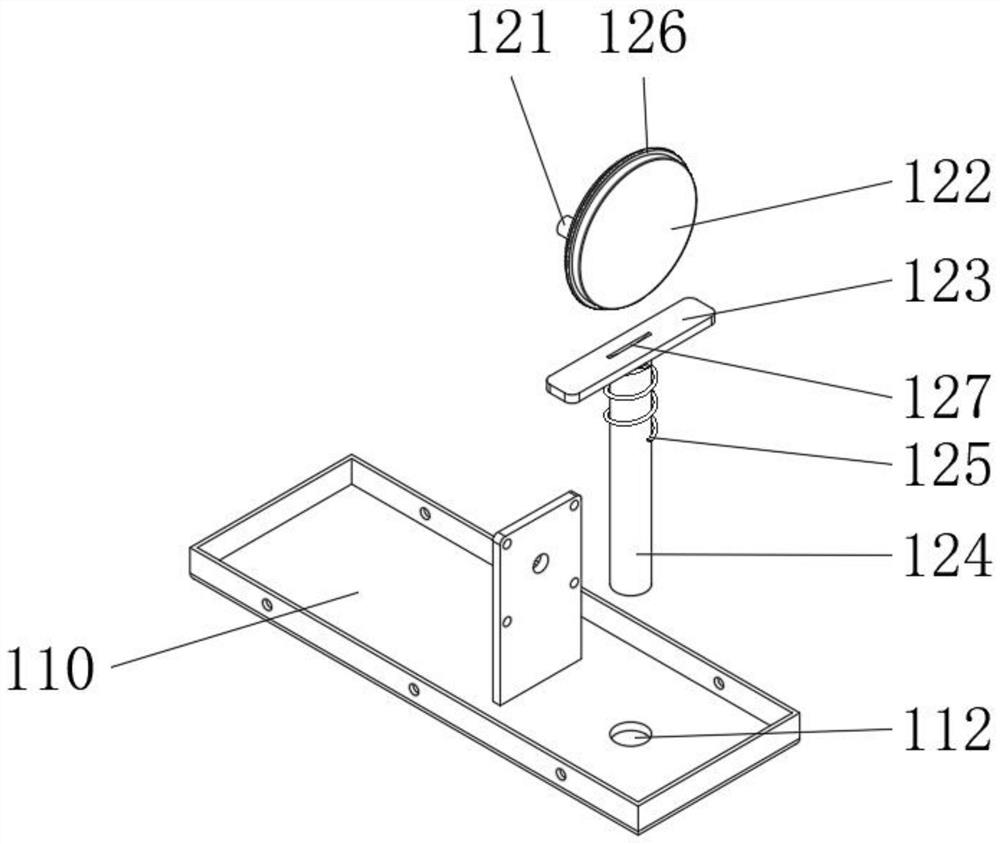

[0048] see Figure 1-Figure 10 As shown, an oncology drug grinding device based on high-frequency vibration is provided, including a vibration grinding structure 100 and a rotating grinding structure 200 located below the vibration grinding structure 100. The vibration grinding structure 100 includes a base plate 110, and a housing 111 is fixed on the base plate 110. The base plate 110 is provided with a perforation 112, and the bottom of the base plate 110 is provided with a second support rod 164. Preferably, the side of the base plate 110 is provided with bolts, and the bolts pass through the base plate 110 and are screwed to the shell 111. A motor 120 is provided above the base plate 110. Specifically An upright mounting plate is arranged above the base plate 110, and the motor 120 is fixed above the mounting plate by several bolts. The output shaft of the motor 120 is coaxially connected with a connecting shaft 121. The motor 120 is preferably a brushless motor using an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com