Semi-automatic plastic extrusion mechanism for cup cover forming

A semi-automatic, cup lid technology, used in applications, household components, household appliances, etc., can solve the problems of not being suitable for small-scale production and processing of cup lids, low integration of injection molding machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

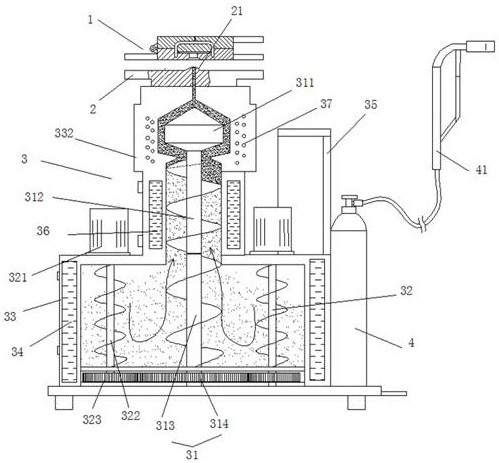

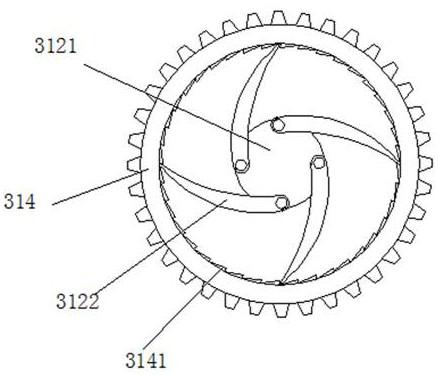

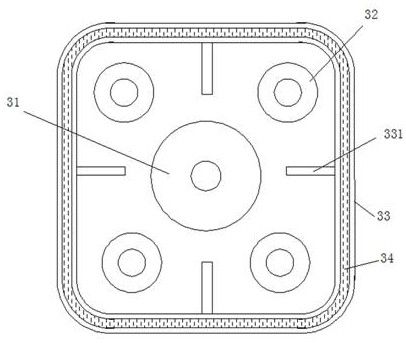

[0028] Such as Figure 1 to Figure 4 As shown, this embodiment designs a semi-automatic plastic extruding mechanism for cup lid molding, including a cup lid injection mold 1 , an injection molding table 2 and a feeding structure 3 .

[0029] The cup lid injection mold 1 includes a lower mold body 11 and an upper mold body 12, a mold cavity 14 is arranged inside the cup lid injection mold 1, and the lower mold body 11 and the upper mold body 12 are mutually rotatably connected. The bottom is provided with an injection port 15 communicating with the mold cavity 14, and the mold cavity 14 is positioned between the lower mold body 11 and the upper mold body 12. In addition, a mandrel is also provided at the bottom of the lower mold body 11, and the injection port 15 is positioned at the center of the mandrel. Directly below, a passage for connecting the mold cavity 14 and the injection port 15 is formed between the lower mold body 11 and the core mold, so that molten plastic can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com