Production device based on PET or BOPET plastic protective net

A technology for production equipment and protective nets, which is applied in the production field of plastic protective nets, and can solve problems such as poor production of plastic nets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

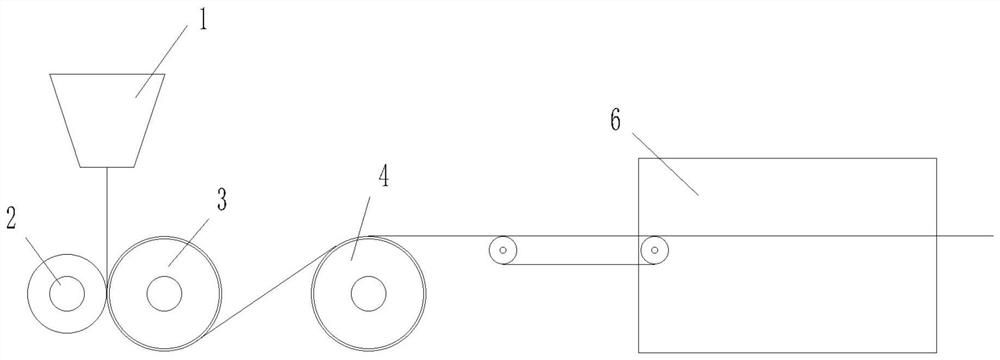

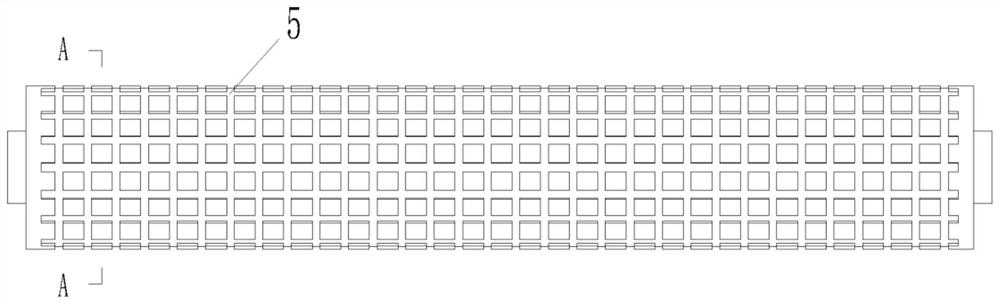

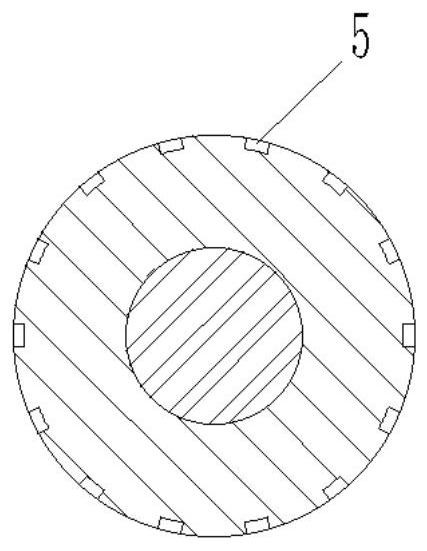

[0021] see Figure 1 to Figure 3 , a production device based on PET or BOPET plastic protective net, the production device includes an extruder 1, a pouring molding and cooling device arranged below the extruder 1, the key is: the pouring molding and cooling device includes a Metal mold roll 2, a cot 3 pressed against the metal mold roll 2, and at least one cooling roll 4, the metal mold roll 2 and the cot roll 3 are paired roller structures, and the roller surface of the metal mold roll 2 is provided with criss-cross grooves 5.

[0022] In order to ensure close contact between the metal mold roller 2 and the rubber roller 3, the metal mold roller 2 and the rubber roller 3 are squeezed tightly by means of a pressure mechanism, and the extrusion force is set at 10-100N. The groove width of the groove 5 is 20-500mm, and the groove depth is 5-100mm. A series of protective net products can be produced according to different needs. At the same time, a certain depth and width of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com