Precision spray-formed metal pipe and its manufacturing method and equipment

A technology of spray forming and manufacturing equipment, which is applied in the field of precision spray forming metal parts and spray forming, which can solve the problems of easy bending operation of horizontal red hot tube billet, waste of metal jet, low deposition efficiency, etc., and achieve fine and uniform microstructure, manufacturing High precision and the effect of saving natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

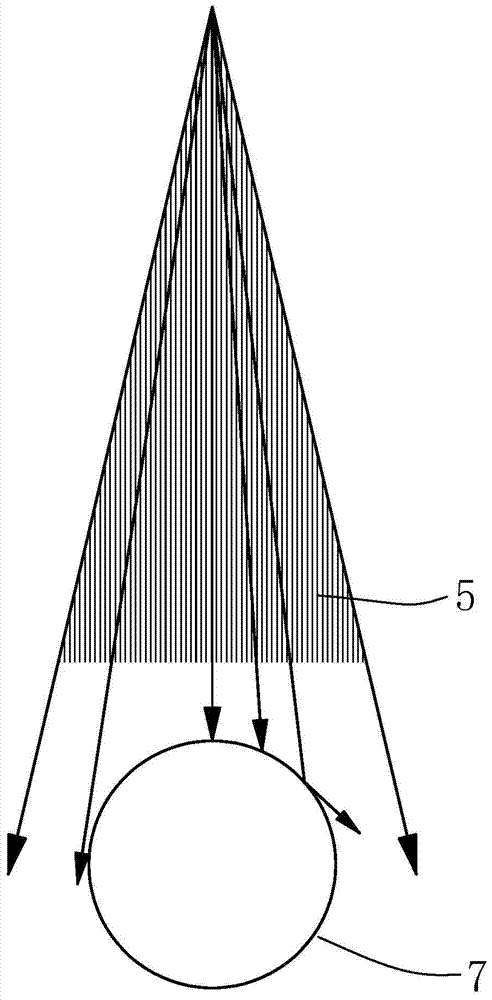

[0040] Through different materials and size limitations, the precision spray-formed metal tube of the present invention has various implementations, for example:

[0041] 1. The wall thickness of the core tube 6 is 1-5 mm, and the material is similar to that of molten metal.

[0042] 2. The wall thickness of the core tube 6 is 1 / 4 of the outer diameter of the whole tube, and the material is a metal different from the molten metal, which can be made into a bimetallic tube.

[0043] 3. The wall thickness of the core tube 6 is 1 / 2 of the outer diameter of the whole tube, and the material is a metal different from the molten metal, which is made of a bimetallic rod. It can be seen that the metal pipes prepared by the present invention also include solid pipes.

[0044] The device of the invention can be used to produce large bimetal broaches. The core pipe 6 is a 35CrMoV seamless steel pipe with an inner diameter of 100 mm and an outer diameter of 180 mm. The metal liquid is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com