Reusable silicon nitride ceramic pouring cup

A technology of silicon nitride ceramics and sprue cups is applied in the field of aluminum alloy casting, which can solve the problems of labor-consuming, material, electric power, high difficulty in making ceramic gates, and high product manufacturing costs, so as to simplify the process cost and reduce the effect of gaps. The effect of heat conduction and improvement of manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners in this application will be further described below in conjunction with the accompanying drawings.

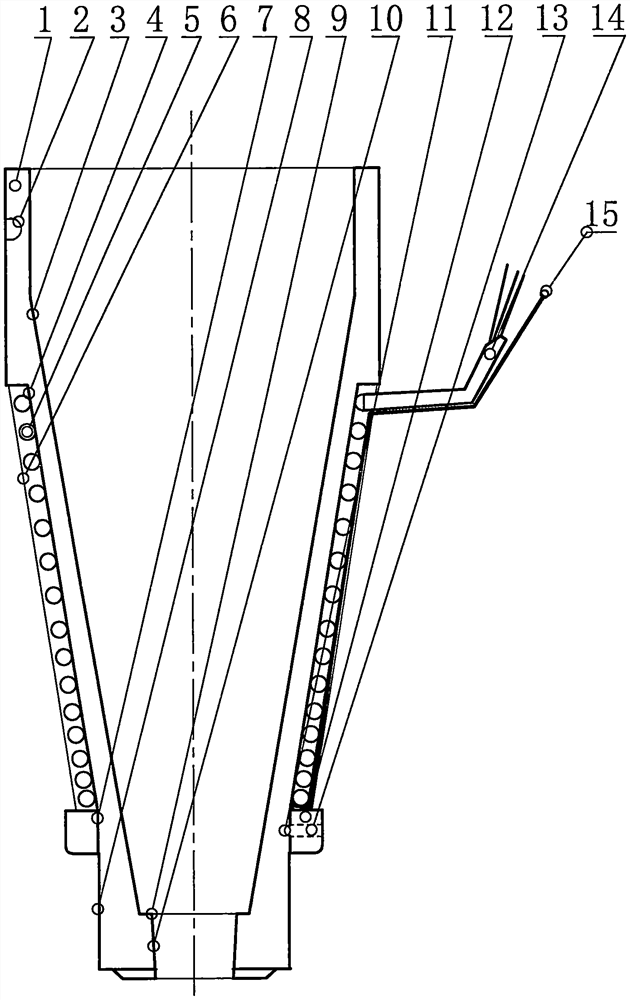

[0016] Such as figure 1 As shown, the application is a silicon nitride ceramic sprue cup that can be reused;

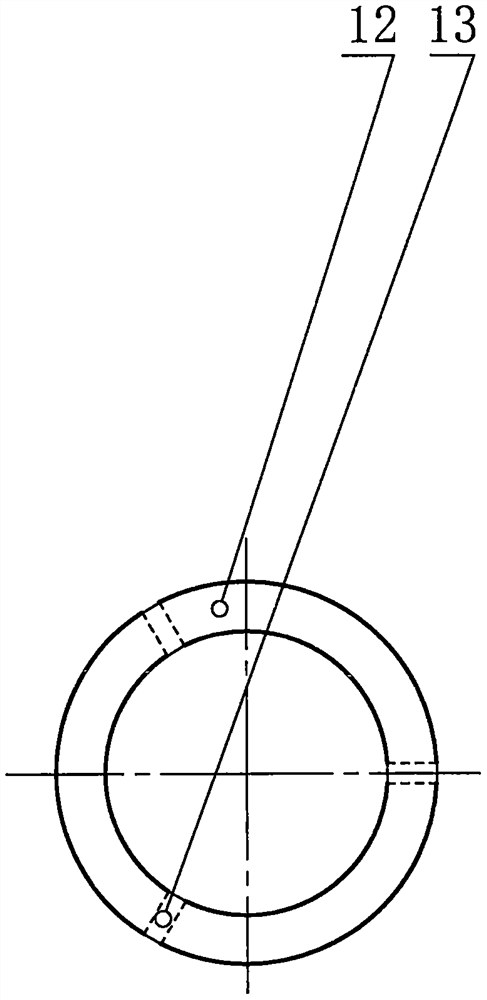

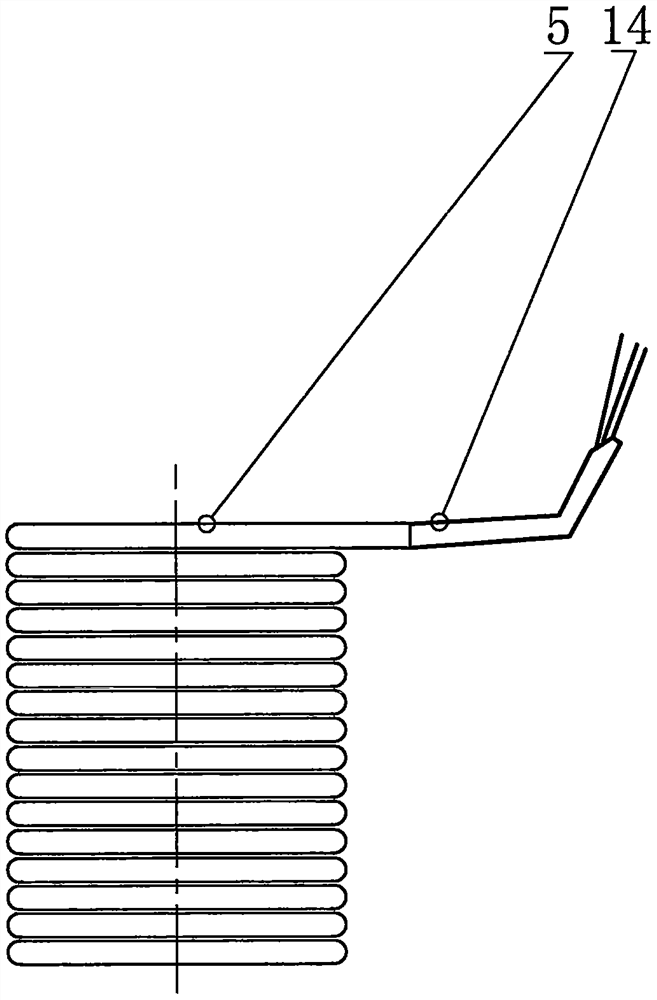

[0017] The reusable silicon nitride ceramic sprue cup includes a sprue cup 1, a sprue frame positioning hole 2, an inner cavity 3, a sprue cup outer wall 4, an electric heating ring 5, a thermally conductive glue 6, and a positioning shoulder 7 , sprue barrel 8, net setting table 9, gate 10, positioning hole 11, positioning ring 12, positioning screw 13, power protection rod 14, thermocouple 15;

[0018] The sprue frame positioning hole 2 is arranged on the outside of the sprue cup 1 for connection with the sprue frame; the inner cavity 3 is arranged in the sprue cup 1 for pouring aluminum liquid; The platform 9 is arranged at the lower end of the inner cavity 3, and the gate 10 is arranged in the net platform 9, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com