Method for improving edge layering of sound insulation pad

A sound insulation pad and edge technology, which is applied in the field of automobile sound insulation pad manufacturing, can solve the problems of prolonging the pressure holding time, increasing the repair time, increasing the production time and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

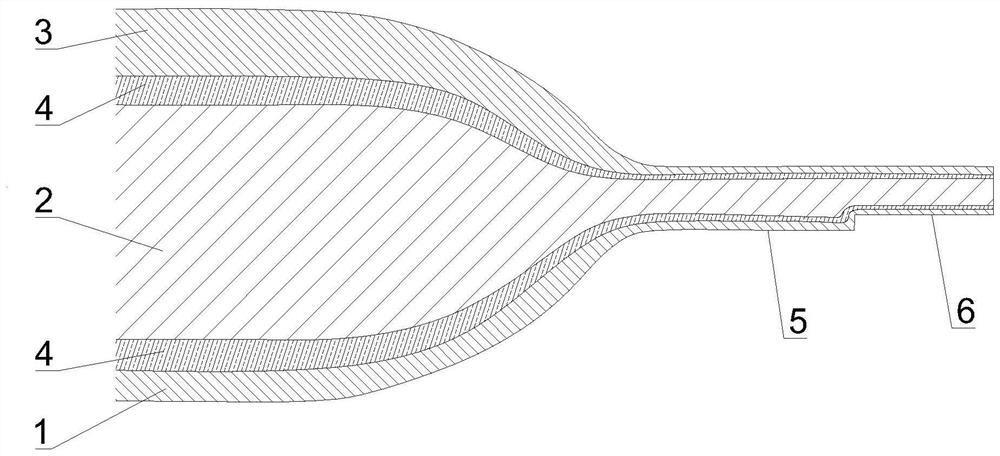

[0019] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and through specific embodiments.

[0020] see figure 1 As shown, this preferred embodiment provides a method for improving the edge delamination of a sound insulation pad, comprising the following steps:

[0021] (1) Design the mold and set the working parameters. The mold in step (1) is in the form of a hot mold and a cold material. The upper and lower molds of the mold are respectively set to a target temperature of 180 ° C, and a plurality of temperature measurement areas are set in the upper and lower molds, generally 4 or 6, and according to the actual measured temperature. The temperature of each temperature measurement area is regulated. After the temperature test is completed, the mold gap is measured, and the aluminum foil paper of about 100mm×100mm is used to roll it into a ball with a diameter of 10-15mm and place it at the mark of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com