Cooling bed discharging and finishing process production line and control method thereof

A production line and finishing technology, applied in the direction of cooling bed, metal rolling, manufacturing tools, etc., can solve the problems of reducing production efficiency due to the width of the cutting edge, limiting the production rate of small-sized rolled pieces, and winding rods, etc., so as to improve production efficiency and Economic benefits, increase blanking and finishing capacity, and increase the effect of production scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the purpose, structure and function of the present invention, the cooling bed blanking and finishing process production line of the present invention will be further described in detail below in conjunction with the accompanying drawings.

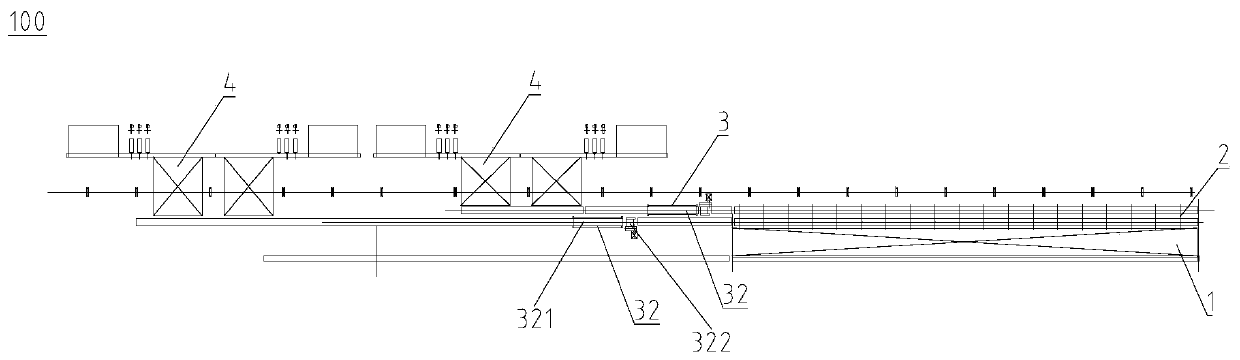

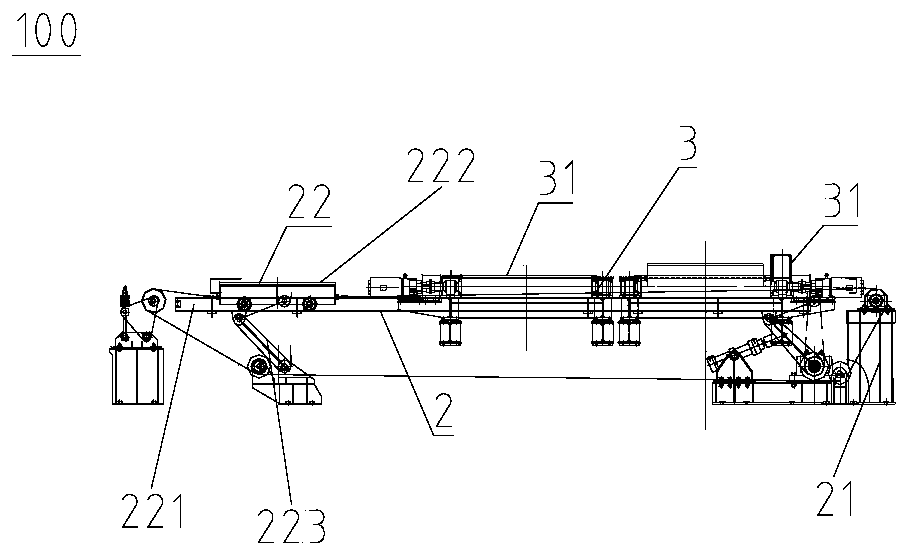

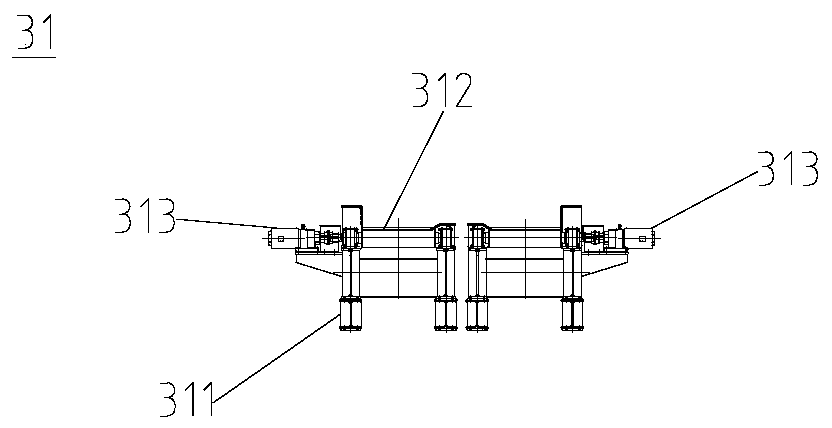

[0021] figure 1 Shown is the structure of the production line 100 of the cooling bed blanking and finishing process according to the embodiment of the present invention. like figure 1 As shown, the cooling bed blanking and finishing process production line 100 includes: a cooling bed 1; a blanking device 2 connected to the output end of the cooling bed 1, and the blanking device 2 includes a plurality of discharges arranged at intervals along its feeding direction end; and a plurality of finishing production lines 3 respectively connected to each discharge end, the length direction of the finishing production line 3 is perpendicular to the feeding direction of the unloading device 2 . Wherein, the unlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com