Sewing equipment

A kind of equipment and sewing technology, applied in the direction of sewing equipment, sewing machine components, sewing machine control devices, etc., can solve the problem of uncontrolled pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

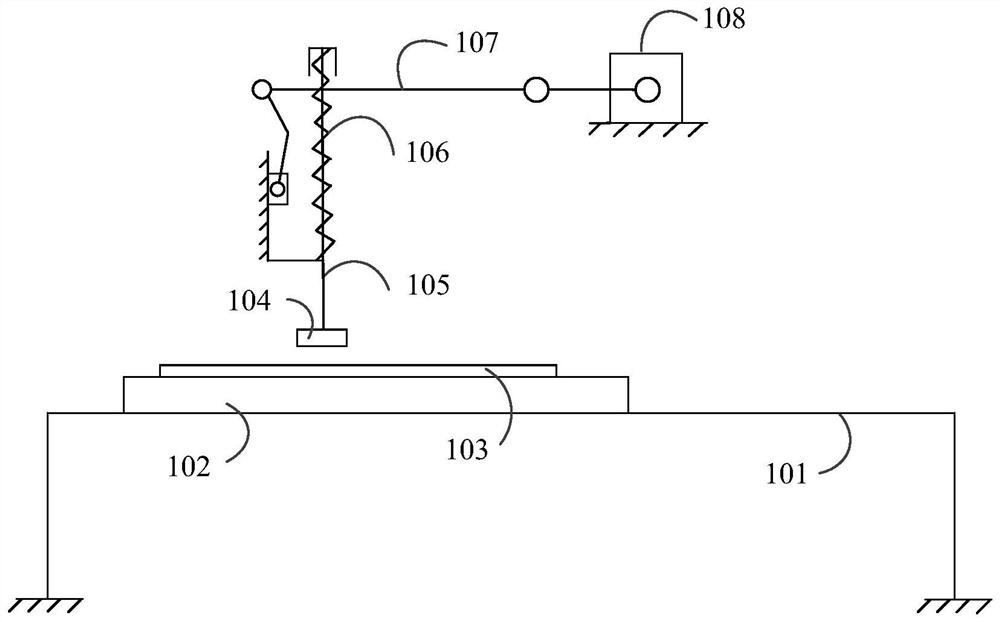

[0034] figure 1 Schematic of sewing equipment for related art. refer to figure 1 In the sewing equipment of the related art, the frame 101, the slit 102, the presser foot 104, the pressure rod 105, the link assembly 107, and the motor 108 are included. A embroidery needle is mounted on the presser foot 104, and the embroidery needle can be slid on the press 104, and the sewing thread is provided in the needle hole of the embroidered needle. The presser foot 104 is fixed to the pressure rod 105, and the link assembly 107 is driven between the press rod 105 and the output shaft of the motor 108, and the motor 108 rotates by the driving link assembly 107 such that the pressure rod 105 moves vertically, which in turn Pressure 104 fixed to the rod 105 in a vertical direction.

[0035] Prior to sewing, the motor 108 drives the presser foot 104 to move the slit 103 by pressing pin 104 on the slit 102. When sewing, the slit 102 performs a translational movement in the X direction and / o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap