Suspension type prepressing structure and using method thereof

A suspended and preloaded technology, applied in building construction, on-site preparation of building components, and formwork processing, etc., can solve the problems of inability to simulate the real situation of concentrated load support formwork, low work efficiency, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

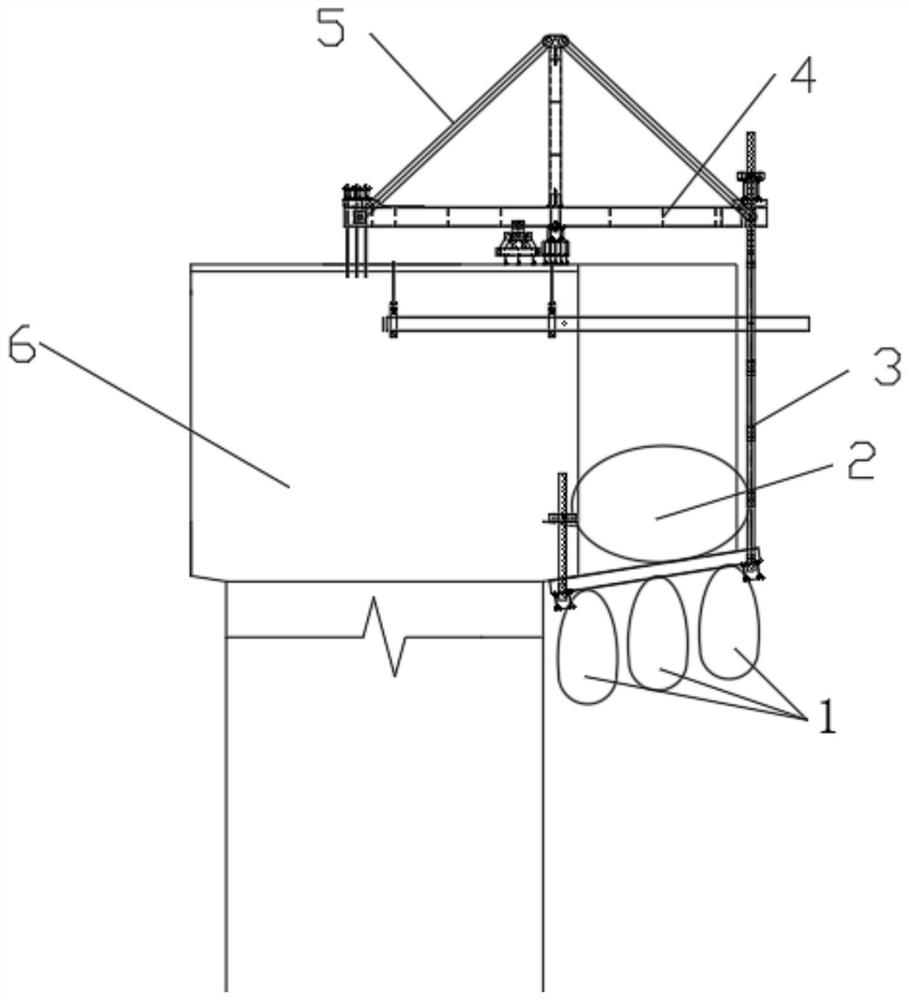

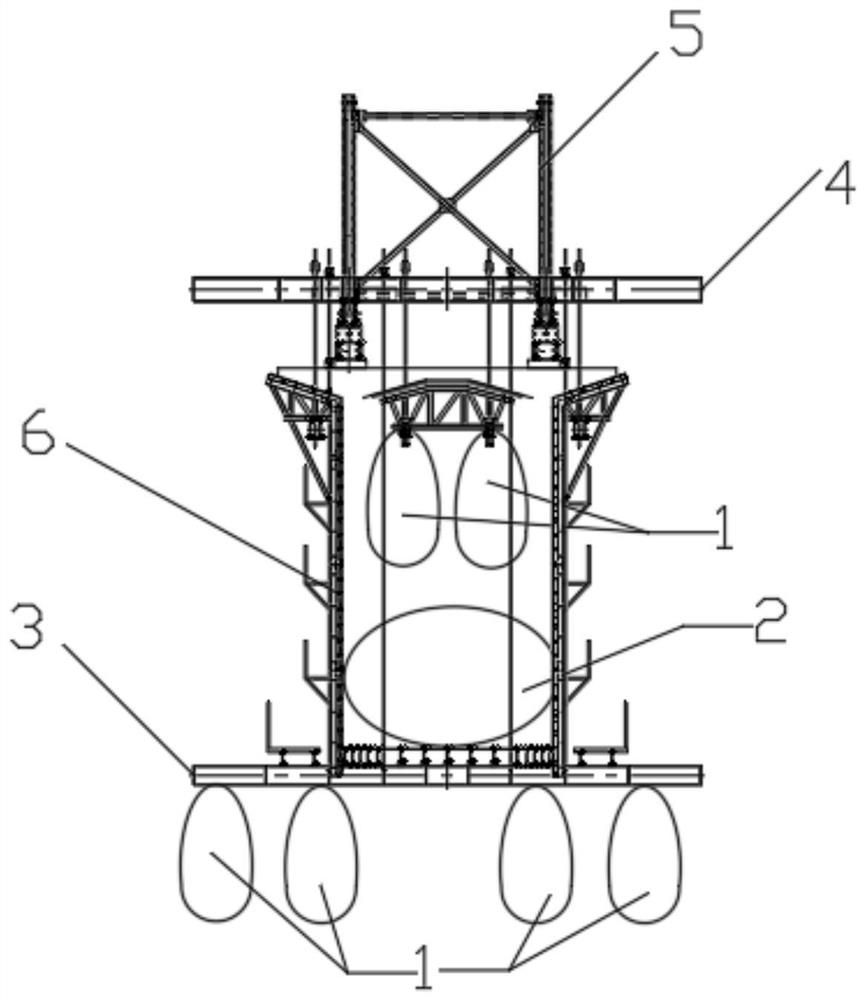

[0020] Such as figure 1 , figure 2 As shown, in this embodiment, a suspended preloading structure includes a cantilever bracket, a hanging basket arranged at the free end of the cantilever bracket and a stacked water bag arranged in the hanging basket, and the stacked water bag is arranged on the hanging basket On the bottom surface of the inner surface, the hanging basket is provided with guardrails surrounding the water bag. The lower surface of the hanging basket is provided with several hooks connected with several hanging water bags.

[0021] When preloading is required, the cantilever bracket is built on the top of the structure, so that the hanging basket is located outside the structure, and the water bag filled with water is put into the hanging basket, and then according to the size of the required load, add a Suspended pockets of water control the loads that the overall structure can provide. When unloading is required, the hanging water bags can be removed one ...

Embodiment 2

[0024] On the basis of the above embodiments, in this embodiment, the hooks are arranged in an array with several rows and several columns. In this way, the number of hanging positions of the hanging water bag can be increased, so as to control the distribution of the hanging water bag to control the distribution of the load according to the needs, improve the efficiency and accuracy of preloading, and facilitate the simulation of the real stress of the structure to enhance the preloading effect.

Embodiment 3

[0026] On the basis of the above embodiments, in this embodiment, a tension sensor is connected between the hook and the hanging water bag. The pressure sensor is used to monitor the pressure exerted by the hanging water bag, so as to accurately monitor the pre-pressing process. And it is convenient to control the hanging water bag according to the needs, so as to ensure the pre-pressing effect. In this embodiment, the pressure sensor is connected with a controller so as to collect and process the data detected by the pressure sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com