Trigger type sliding sleeve opening and closing tool

A sliding sleeve switch and trigger technology, which is applied in wellbore/well components, earth-moving drilling, sealing/packing, etc. Improvement of work efficiency, difficulties in work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

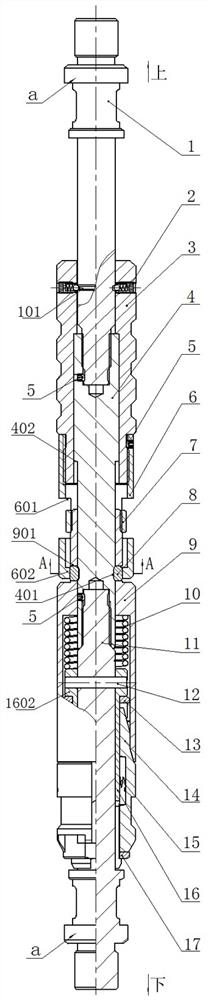

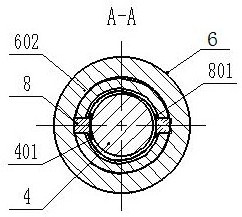

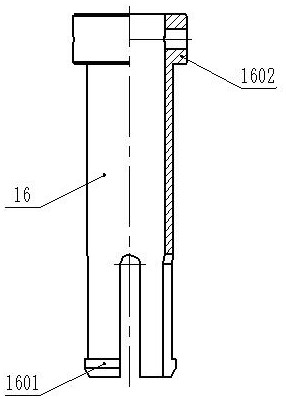

[0028] See figure 1 — Figure 4 , the trigger type sliding sleeve switch tool provided by the present invention, its external dimensions: the maximum diameter is at least 20mm, the length is at least 200mm, including a rod-shaped body, a lock that can be radially and elastically expanded fixedly sleeved on the rod-shaped body The block assembly and the movable sleeve are set on the rod-shaped body and the conical sleeve 9 that axially cooperates with the lock block assembly to limit the radial expansion of the lock block assembly, the thrust spring 10 arranged between the lock block assembly and the conical sleeve 9, and the movable The slider 8 that can move radially on the rod-shaped body and axially restricts the upward movement of the tapered sleeve 9, and the slider 8 that can be movably sleeved on the rod-shaped body and temporarily fixed by elastic positioning components can limit the radial movement of the slider 8 Weighting assembly; when the elastic positioning part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com