Blade root bolt extraction device of wind power blade

A technology for wind turbine blades and extraction devices, which is applied in the assembly of wind turbines, wind power generation, and wind turbines in the same direction as the wind, and can solve the problems of bolt waste, blade root bolt numbering without systematic management, and complicated work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] It should be explained that the bolt holder described in the present invention is a cylindrical bolt holder used in the experimental work room, and the holes matching the bolt holder are all circular holes.

[0080] The terms "length", "width", "upper", "lower", "left", "right", etc. indicating the orientation or positional relationship are based on the orientation or positional relationship shown in the drawings, and are only for the convenience of describing the present invention and Simplified descriptions, rather than indicating or implying that a referred device or element must have a particular orientation, be constructed, and operate in a particular orientation, and therefore should not be construed as illustrative of the invention.

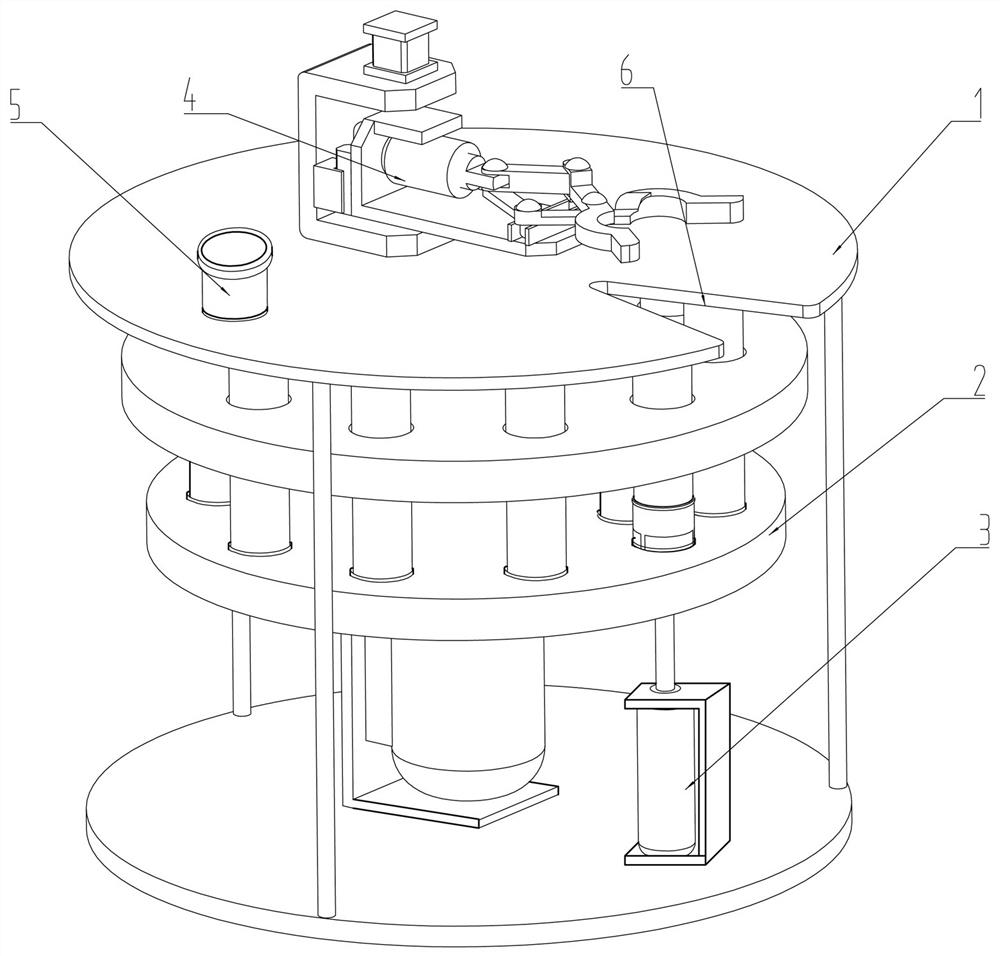

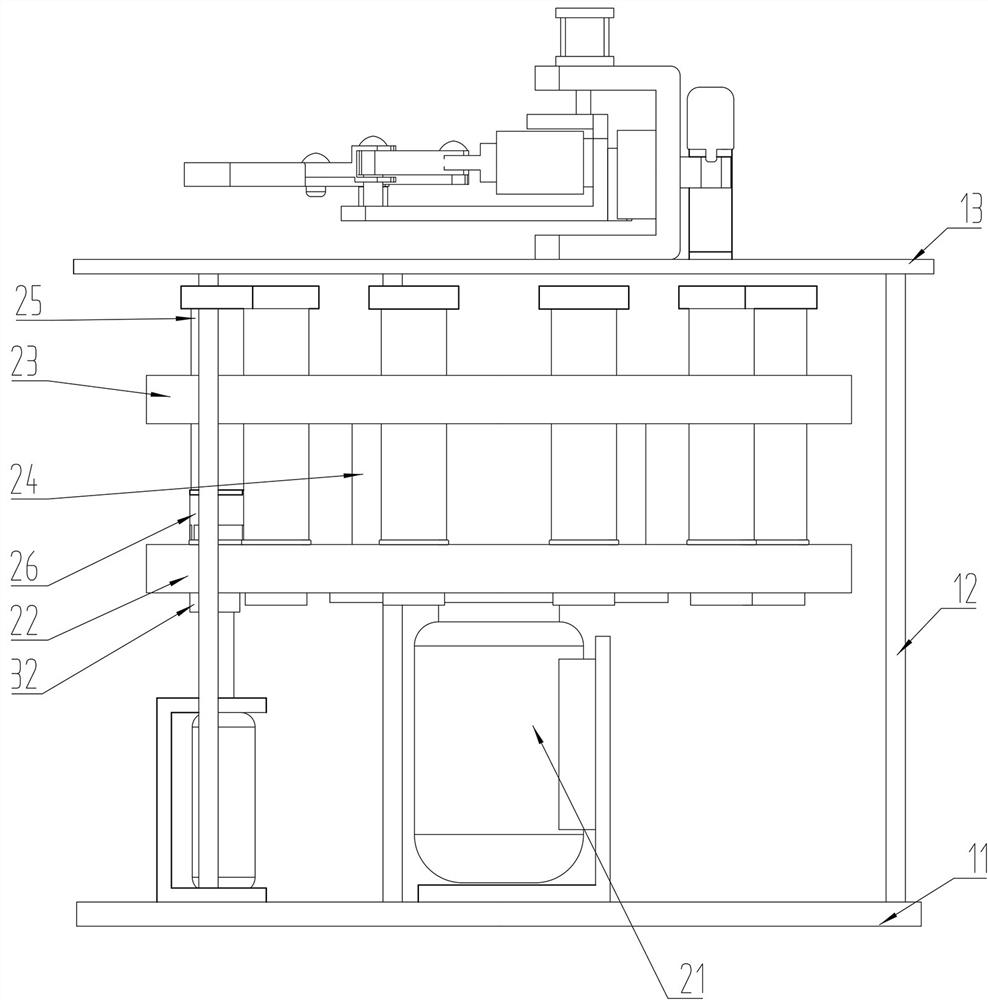

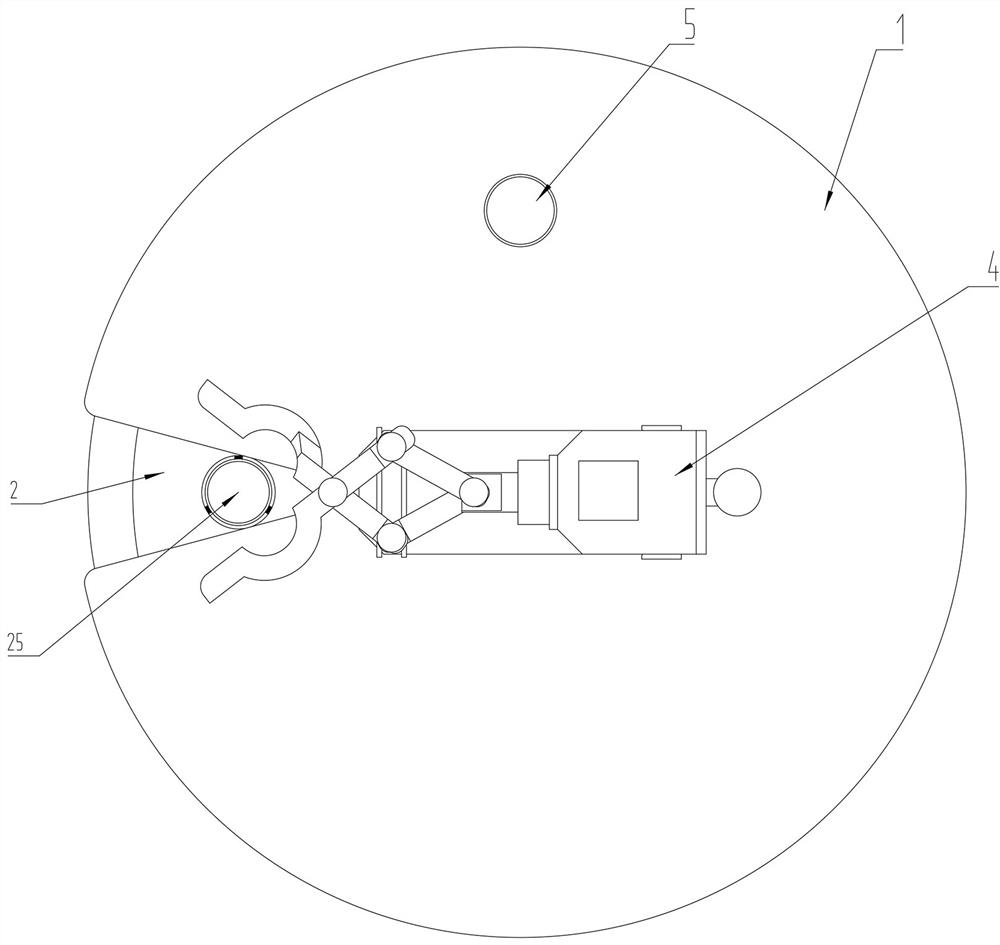

[0081] Such as figure 1 As shown, the fixed frame 1, the first motor 21 fixedly connected to the lower part of the fixed frame 1, the rotating device 2 fixedly connected to the output shaft of the first motor 21, and the bolts circu...

Embodiment 2

[0096] Such as Figure 7 As shown, the receiving pipe 5 can be arranged outside the device, the second motor 413 and the shaft seat 411 can be eliminated, and the second slide rail is fixedly arranged on the top plate 13, the support 412 is Z-shaped, and the support 412 The second slide block is fixedly arranged at the lower end, and the fourth cylinder is fixedly connected to the top plate 13, and the piston rod of the fourth cylinder is fixedly connected to the outer surface of the U-shaped bottom of the support 412. When the clamp clamps the bolt holder 25 , the piston rod of the second cylinder 415 contracts into the cylinder, so that the clamping mechanism is lifted upwards, the piston rod of the fourth cylinder protrudes out of the cylinder, and the entire clamping device is pushed out of the fixed frame 1, so that the clamping bolt frame 25 is located Right above the receiving pipe 5 , the piston rod of the second cylinder 415 stretches out of the cylinder, and the bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com