A Method of Controlling Flow Accuracy of Additive Manufacturing by Predicting Scanning Speed

A technology of additive manufacturing and scanning speed, which is applied in the direction of flow control using electric devices, etc., can solve problems such as difficulty in realization and complex nozzle structure, and achieve the effect of improving wire width accuracy, reducing unnecessary errors, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

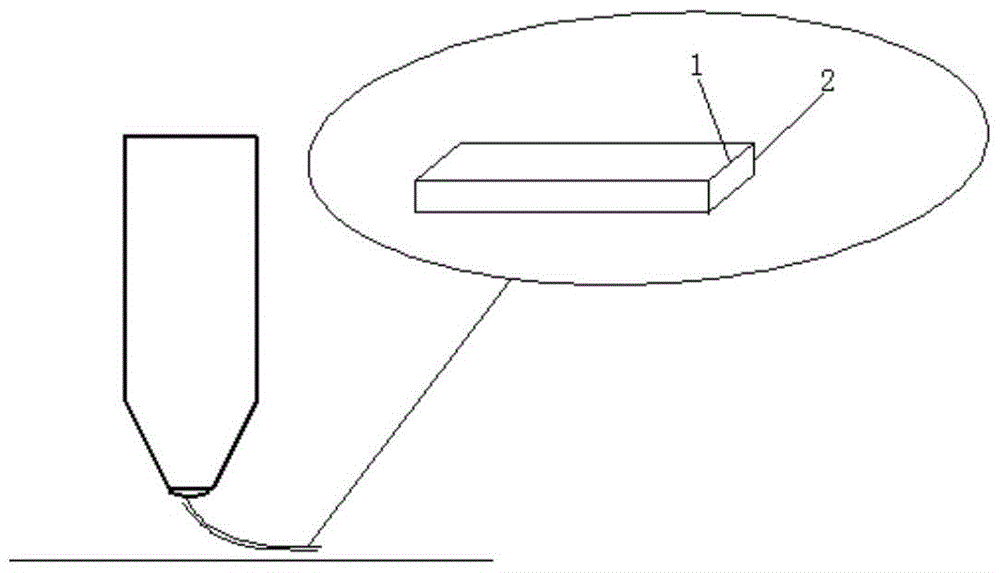

[0018] The present invention will be further described below in conjunction with accompanying drawing.

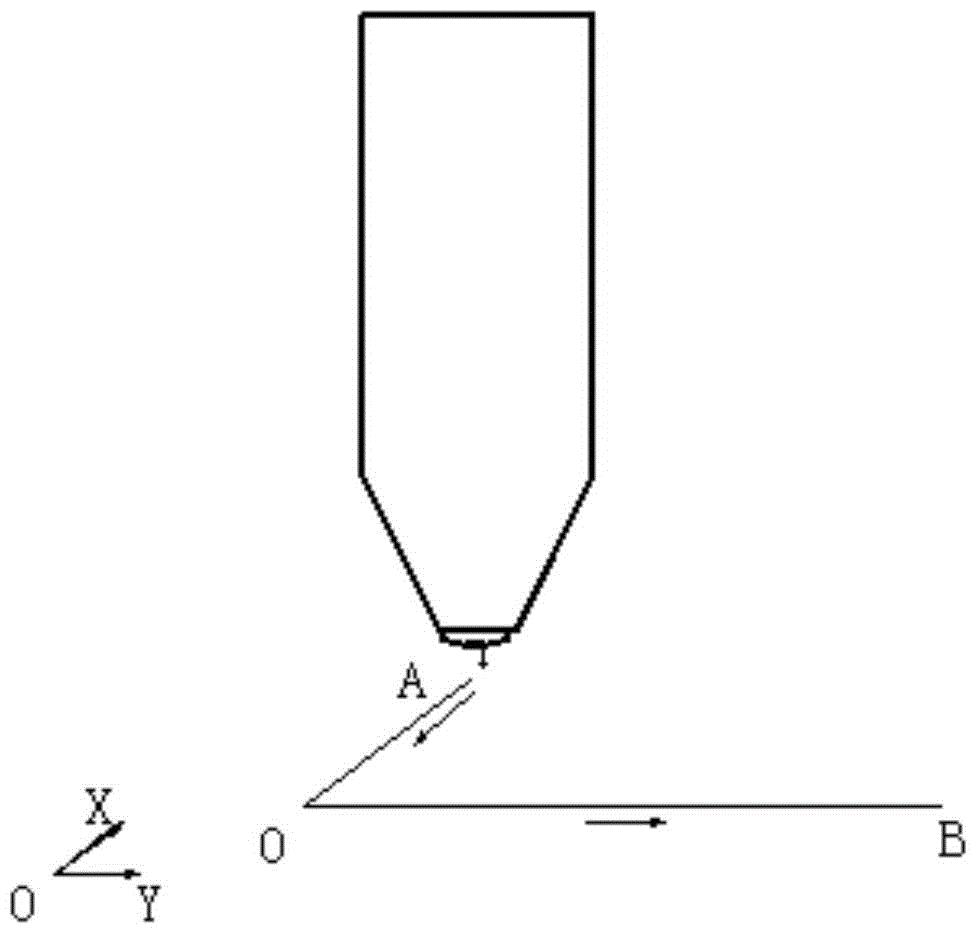

[0019] The purpose of the present invention is to avoid the influence of the actual motion trajectory of the nozzle on the wire width accuracy as far as possible, and its technical basis is the mechanical structure of the working platform. The source of the movement speed of the nozzle is the speed synthesis of the two servo motors of the X and Y axes, so the movement of the nozzle is affected by the working characteristics of the servo motor.

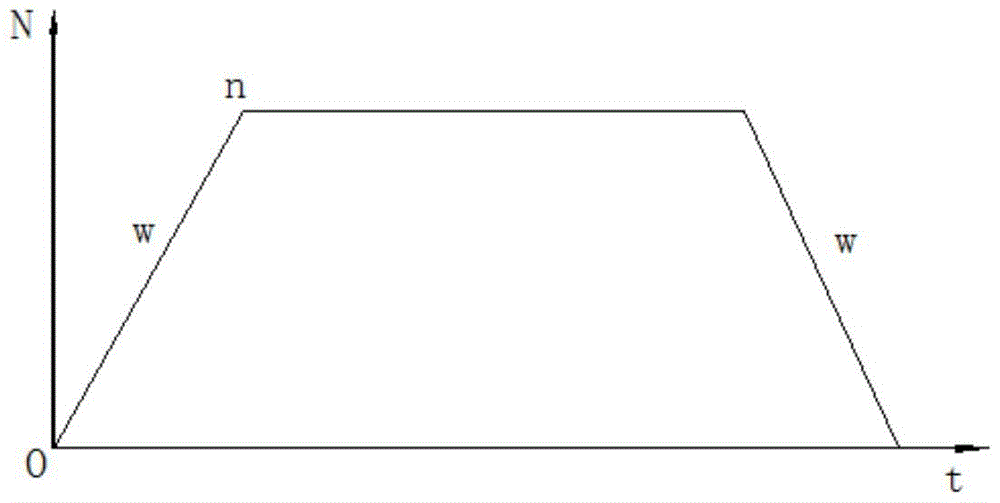

[0020] Such as figure 1 As shown, it takes an acceleration time for the motor speed to reach the set n from the initial speed. The motor drives the bearing to rotate to make the nozzle advance in the direction of the X (Y) axis. According to the relationship between the mechanical transmission screw and the lead, the following relationship can be obtained:

[0021]

[0022] Where v is the axial speed, n is the motor speed, P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com