Solid heat storage device with high-stability heat storage and high-efficiency heat release

A high stability, heat storage device technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problem of lack of thermal stress release components, low thermal energy utilization rate, and large resistance of steam heat release circulation channels. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

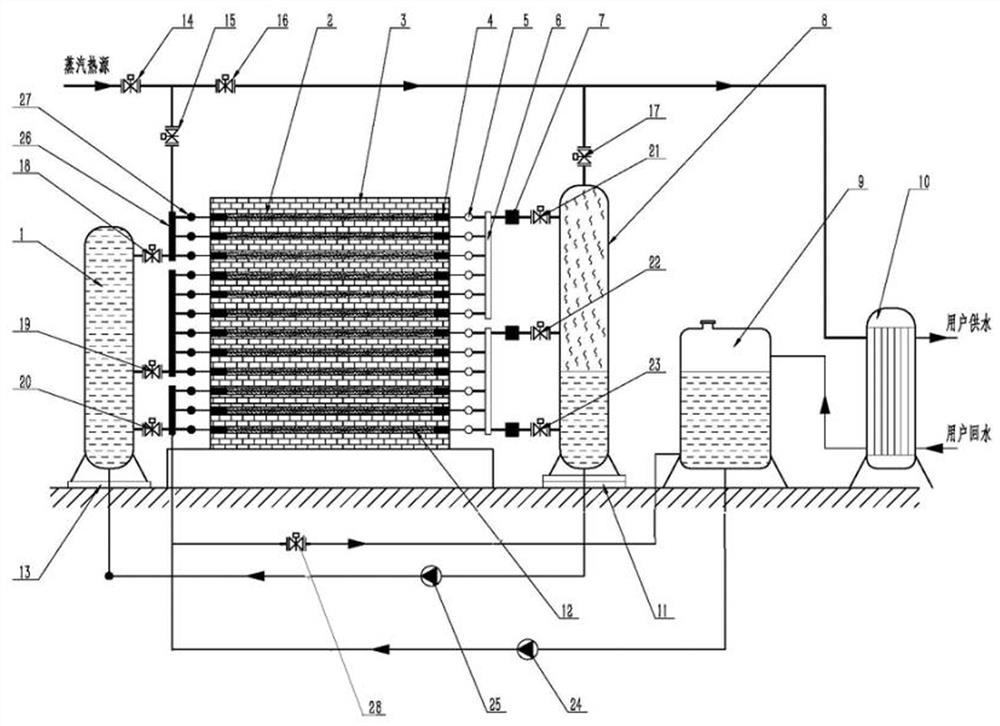

[0015] As shown in Figure 1, water supply tank 1, solid heat storage body 3, heat exchange tube 12, flexible head 4, output horizontal main pipe 5, output longitudinal main pipe 6, input vertical main pipe 26, and input horizontal main pipe 27 , a saturated steam tank 8, a water storage tank 9, a heat exchanger 10, a fixed support 13 is provided at the lower part of the water supply tank 1, and a sliding support 11 is provided at the lower part of the saturated steam tank 8; The heat transfer pipe between the output longitudinal main pipe 6 and the saturated steam tank body 8 is evenly distributed with expansion joints 7 for buffering the axial thrust of the heat exchange tube group on the saturated steam tank body 8; the steam heat source passes through the pipeline, the main valve 14 And the heat storage valve 15 is connected with the input longitudinal main pipe 26 connected with the high-level circulating water valve 18 and the multiple input horizontal main pipes 27 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com