Kinetic energy rotating nozzle for water distribution in cooling tower

A technology of rotating nozzles and cooling towers, applied in the field of cooling towers, can solve problems such as affecting the efficiency of cooling towers and unfavorable combination of nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

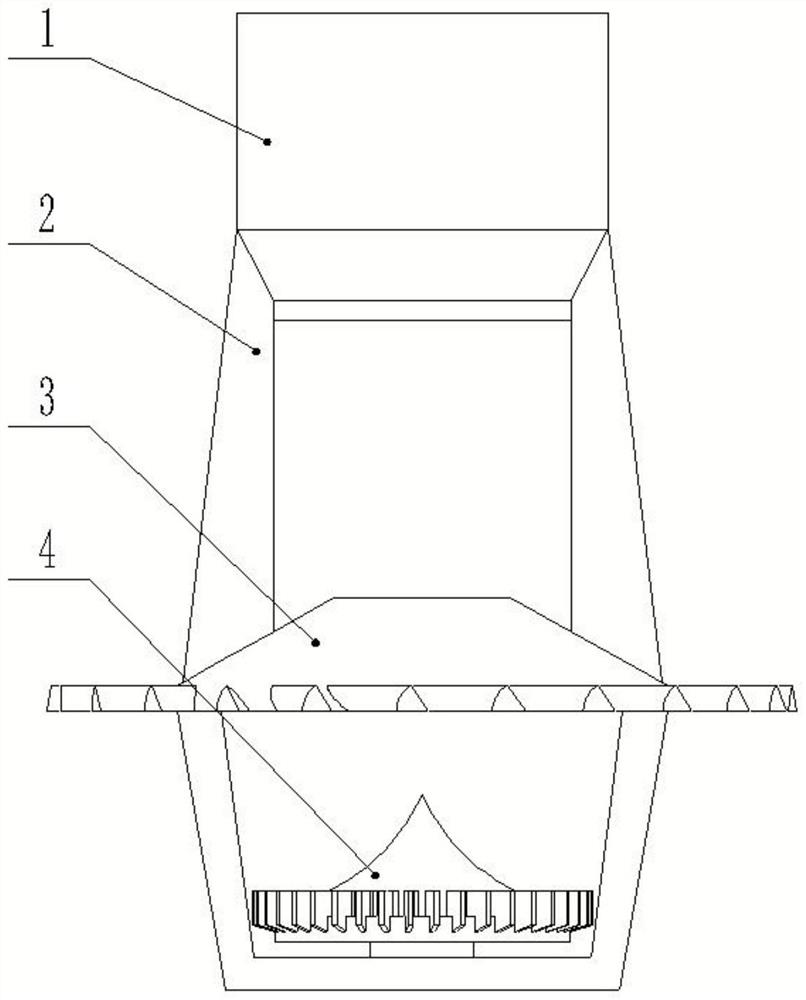

[0026] Example 1, such as figure 1 As shown, a kinetic energy rotating sprinkler for distributing water in a cooling tower includes a tube 1 and a nozzle body, one end of the tube 1 is connected to an external circulating water pipe, and the other end of the tube 1 is connected to the nozzle body.

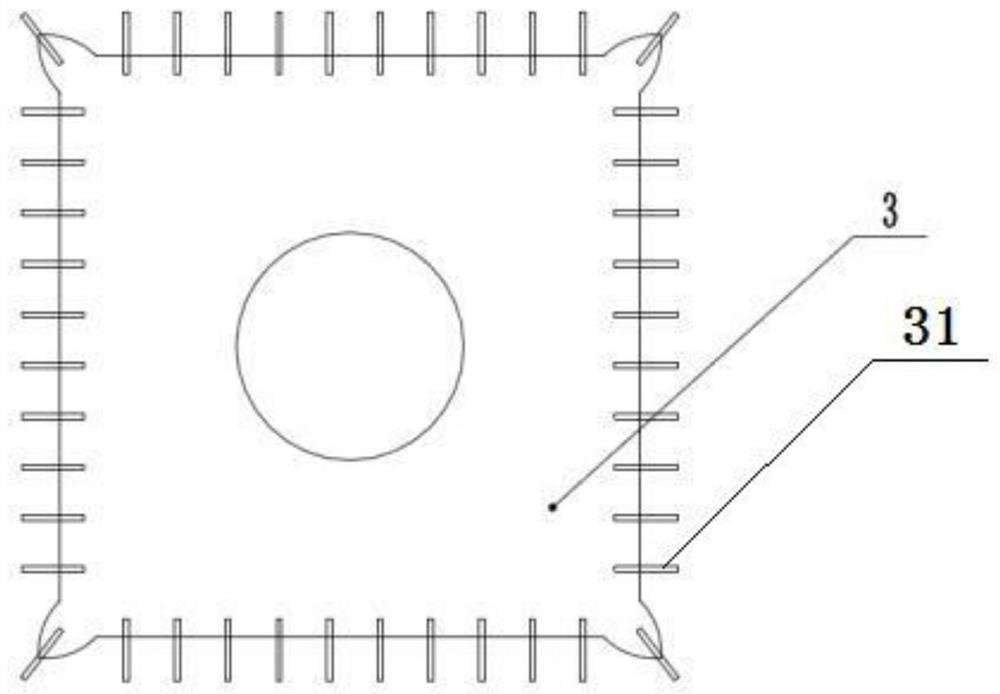

[0027] The spray head body includes a first splash plate 3 and a second splash plate 4, and two symmetrical fixed pulleys are used between the first splash plate 3 and the second splash plate 4 and between the splash plate and the tube. The ribs 2 are connected, and the fixed tension ribs 2 are in a flat oval shape.

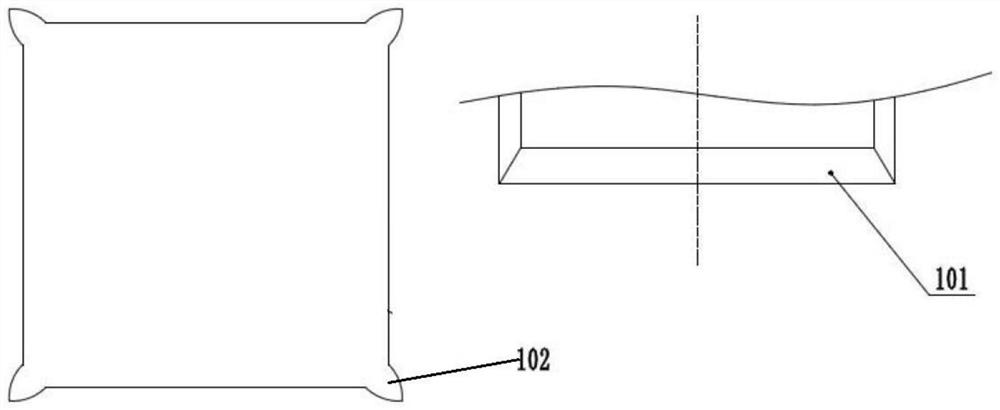

[0028] Such as figure 2 As shown, the upper part of the pipe tube 1 is in the shape of a vertical cylinder, the upper part of the tube tube 1 is connected with the external circulating water pipe, and the upper part of the tube tube 1 can be connected with the external circulating water pipe by thread or other methods; the lower part of the tube tube 1 is in the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com