Self-adaptive control method for stability and roundness of ultra-large ring piece in radial and axial rolling process

A self-adaptive control, axial rolling technology, applied in the field of ring rolling, can solve the problems of fluctuation, difficulty of rolling roundness and stability control of super-large ring rolling, long forming process time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with accompanying drawing:

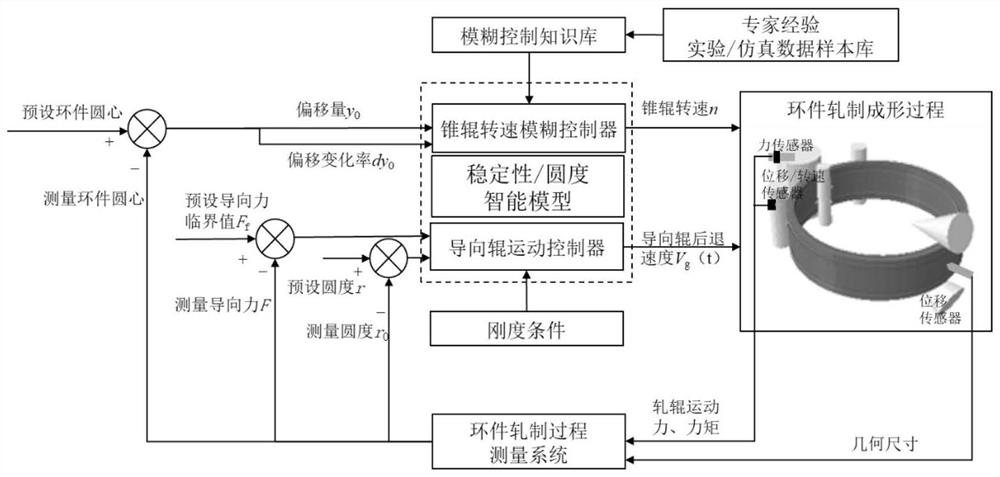

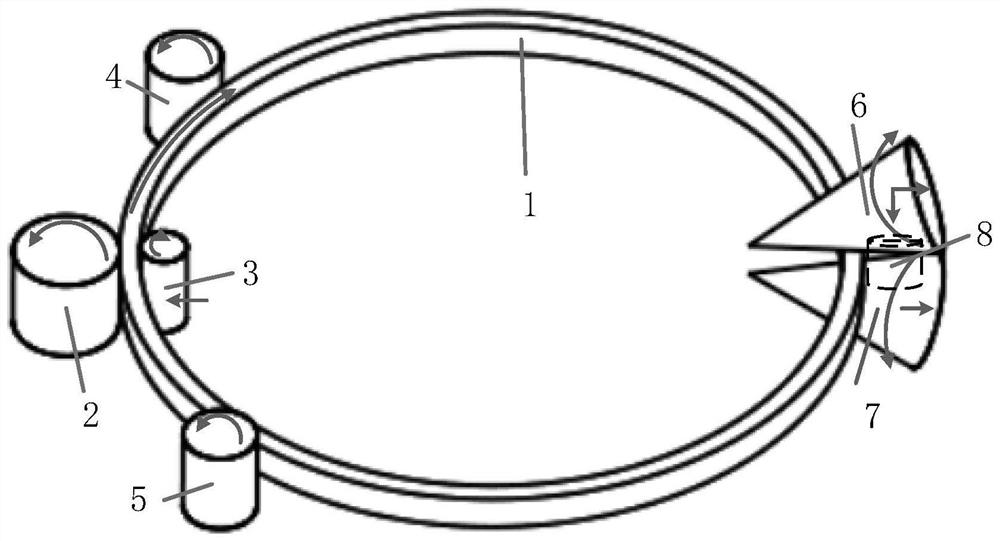

[0059] The present invention comprehensively utilizes metal forming principles and intelligent control theory methods, and proposes the following figure 1 The research idea shown is based on the conventional motion planning control of radial and axial ring rolling equipment, and the roundness and stability change characteristics of super-large ring rolling are identified from the process measurement information; in addition, the control is learned and extracted from historical data. Rules, build ring rolling process control knowledge base, design adaptive controller and control strategy, control ring rolling roundness and stability by real-time adjustment of roll motion, and realize geometric size and deformation of ultra-large ring radial and axial rolling process State double closed-loop control.

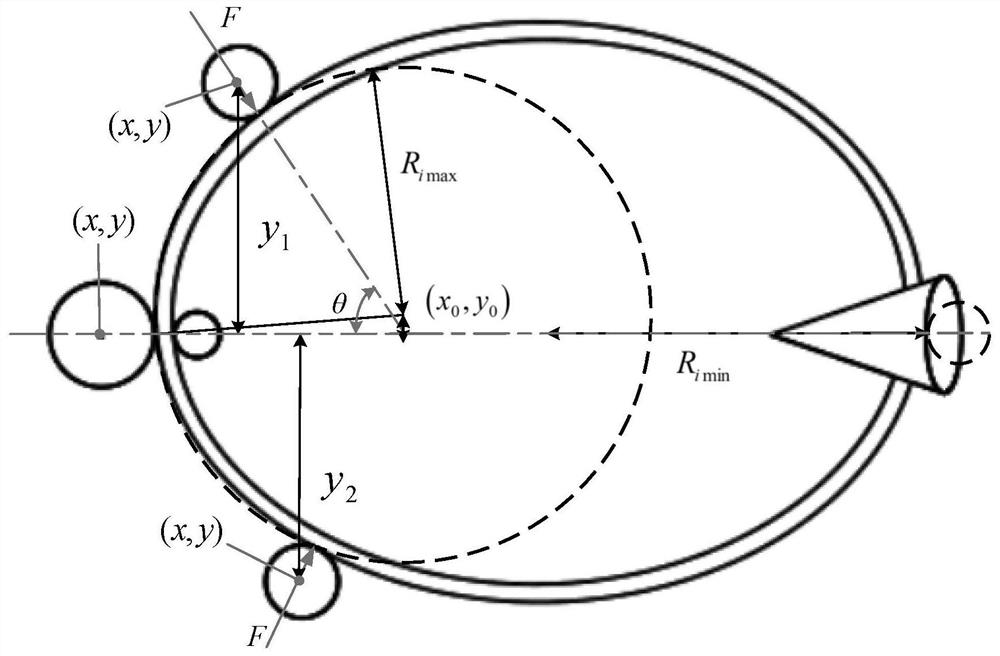

[0060] Among them, the distance y between the lower guide roller and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com