Flame cutting equipment for round tube processing

A flame cutting and round pipe technology, applied in metal processing equipment, gas flame welding equipment, welding equipment, etc., can solve the problems of low cutting efficiency, pipe wall thickness, limited practicability and functionality, etc., to improve cutting efficiency, The effect of shortening the cutting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

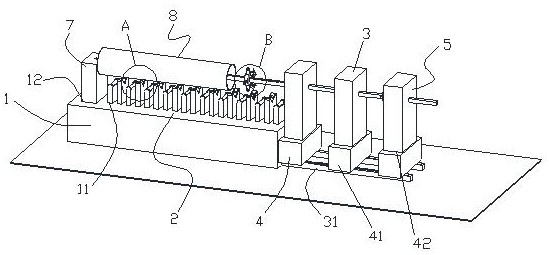

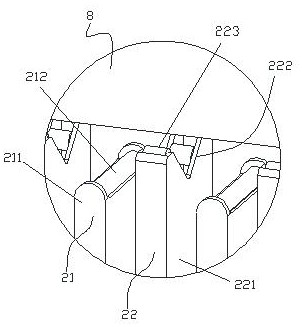

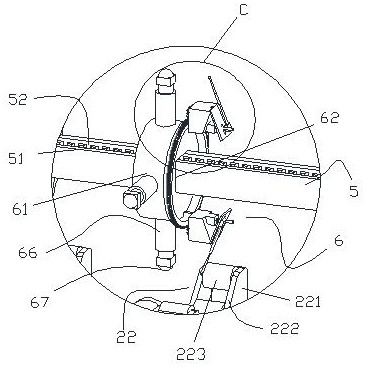

[0037] see Figure 1 to Figure 8As shown, this embodiment is a kind of flame cutting equipment for round pipe processing, including a support base 1 arranged horizontally, and a plurality of first support grooves 11 are arranged on the support base, and the first support grooves are provided with The support assembly 2, the support assembly includes a first support assembly 21 arranged in the first support groove, a second support assembly 22 is also arranged in the first support groove, and the first support assembly, The second supporting components are arranged in a staggered manner; one end of the supporting base 1 is provided with a driving member 3, the bottom end of the driving member 3 is provided with a first lifting member 4, and the driving member is provided with a guide rail member 5, The guide rail is arranged horizontally, and the guide rail is provided with a plurality of pipe cutting assemblies 6 which are slidably matched with the guide rail, and the guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com