A multi-axis motion and serial manipulator compound drive four-mirror polishing machine tool

A multi-axis motion, manipulator technology, applied in manipulators, grinding drives, optical surface grinders, etc., can solve the problems of uncertain surface quality, poor processing flexibility, poor adaptability to complex optical surfaces, etc., to achieve fast response speed, guaranteed The effect of machining quality, increased flexibility and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

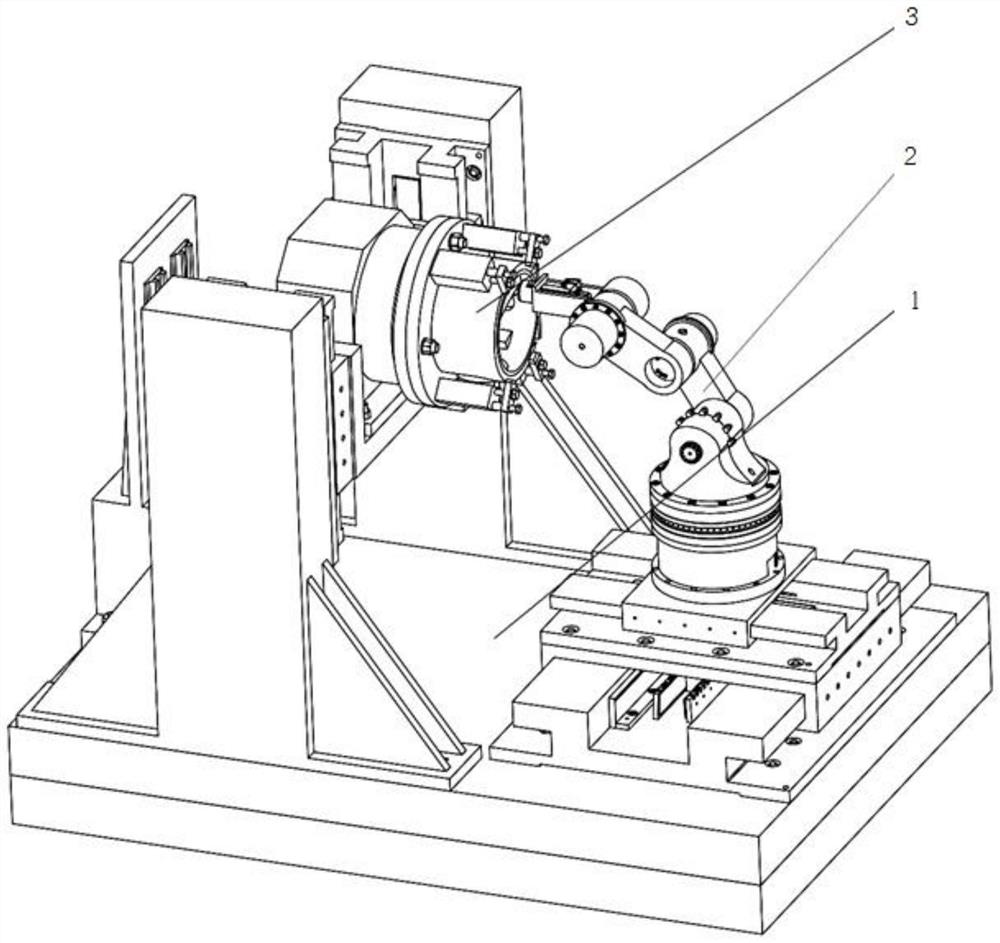

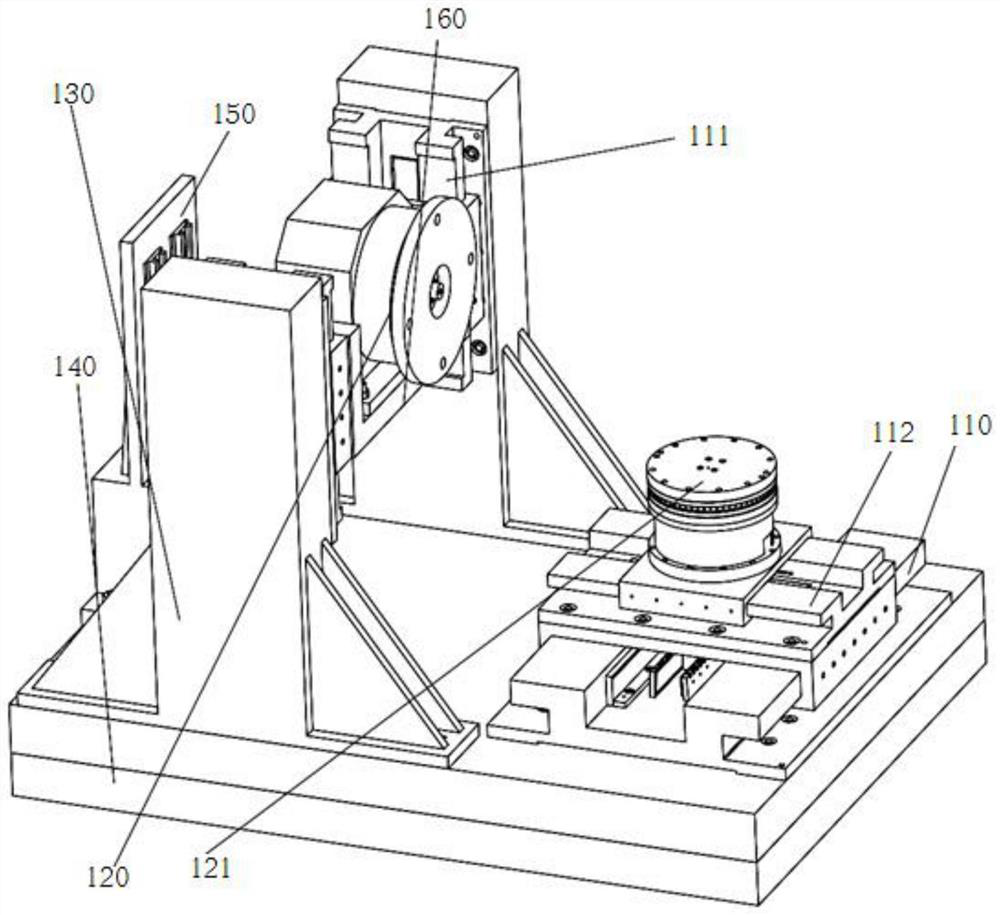

[0054] see e.g. figure 1 , a multi-axis motion and tandem manipulator compound drive four-mirror polishing machine tool, including a five-axis motion machine tool 1, a serial manipulator tool 2, and a workpiece fixture device 3, wherein the five-axis motion machine tool 1 includes five degrees of freedom, three of which are Translational degrees of freedom and two rotational degrees of freedom, arranged horizontally.

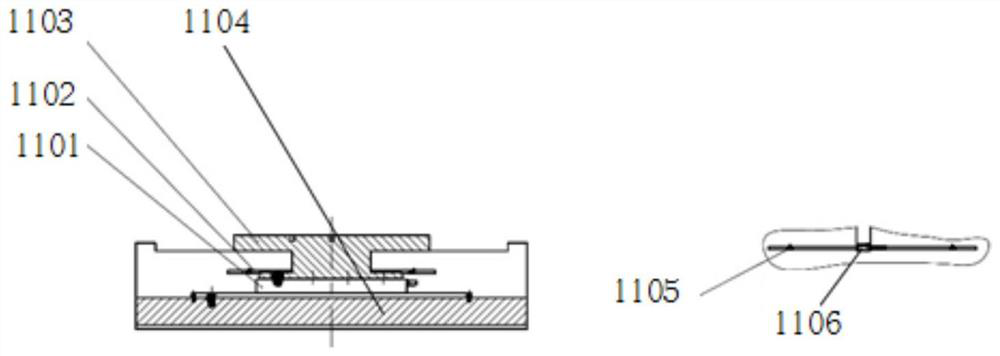

[0055] The workpiece fixture 3 is fixedly installed on the B-direction rotating platform assembly 120 of the moving machine tool through screws or bolts; one end of the serial robotic arm tool 2 is fixedly installed on the C-direction rotating platform of the moving machine tool through screws or bolts On the assembly 121 , a polishing tool head 270 is provided at the other end of the serial robotic arm tool 2 , and the serial robotic arm tool 2 cooperates with the workpiece fixture 3 to perform polishing processing on the optical curved surface of the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com