Bidirectional safety tongs for elevator and elevator device

A technology of safety gear and elevators, which is applied in transportation and packaging, slack adjusters, elevators, etc., and can solve problems such as the failure of the connecting rod to buffer, the slipping and breaking of the brake pad surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

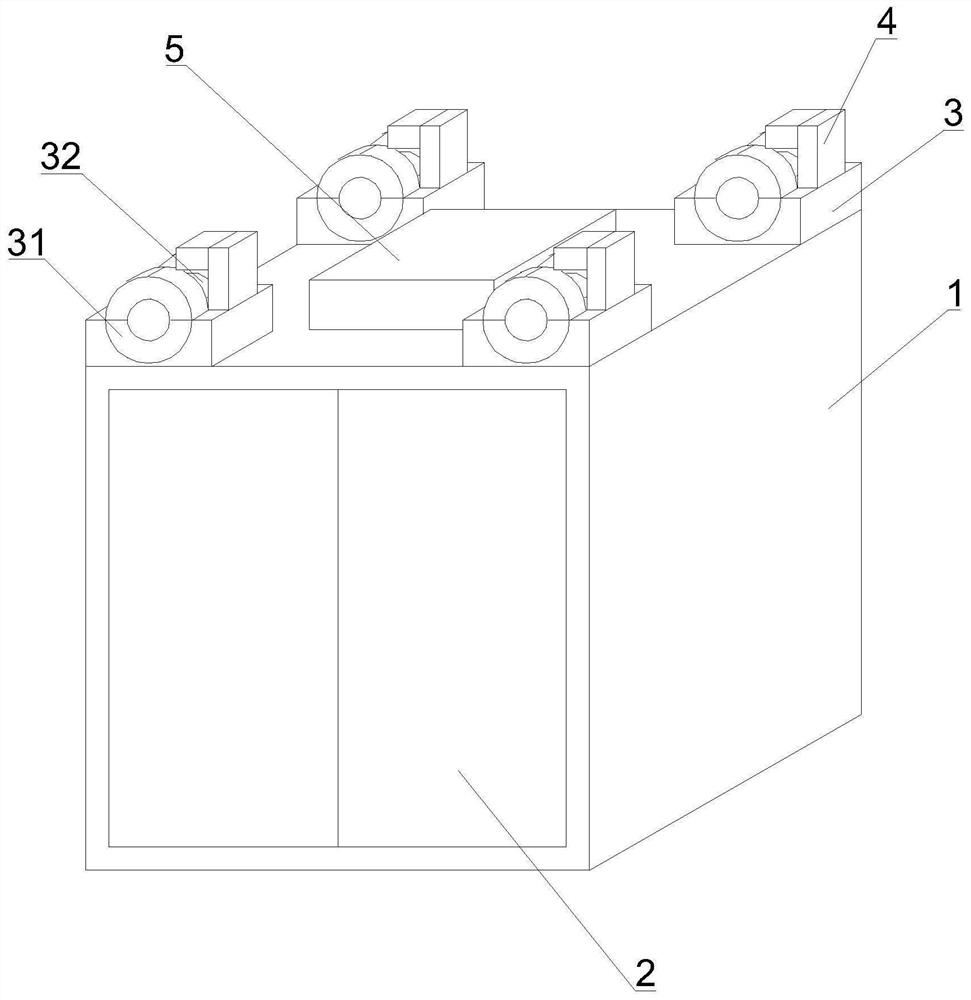

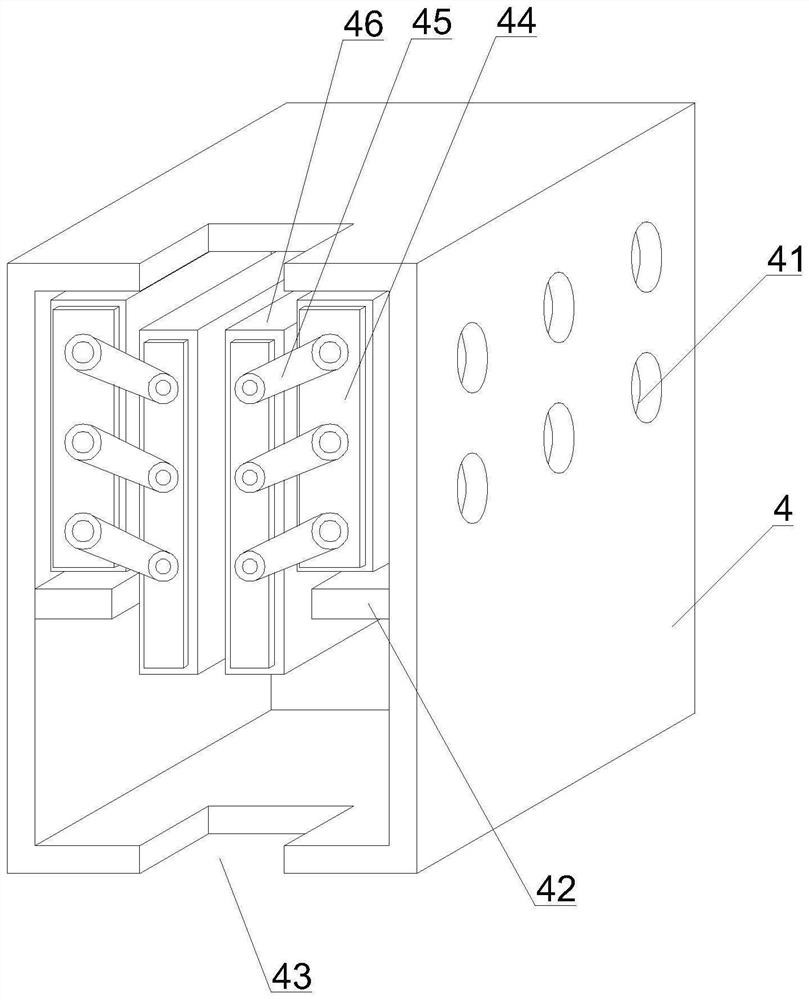

[0043] Such as Figure 1-8As shown, the present invention provides a two-way safety gear for elevators, including a two-way safety gear 4, a push and fix mechanism 44 is fixedly installed on the inner surface of the two-way safety gear 4, and a push and fix mechanism 44 is movably installed on the outer surfaces of both sides of the push and fix mechanism 44. A telescopic combining mechanism 45, one end of the telescopic combining mechanism 45 is fixedly connected with a safety brake mechanism 46, and two-way safety gear 4 is provided with cooling holes 41 on both sides of the outer surface, and a fixed plate 42 is fixedly connected on the inner wall surface of the two-way safety gear 4 , push the outer surface of the fixing mechanism 44 to be fixedly connected to the outer surface of the fixed plate 42, the upper and lower sides of the two-way safety gear 4 are provided with a wire hole 43, and the inner sliding connection of the telescopic combining mechanism 45 is connected ...

Embodiment 2

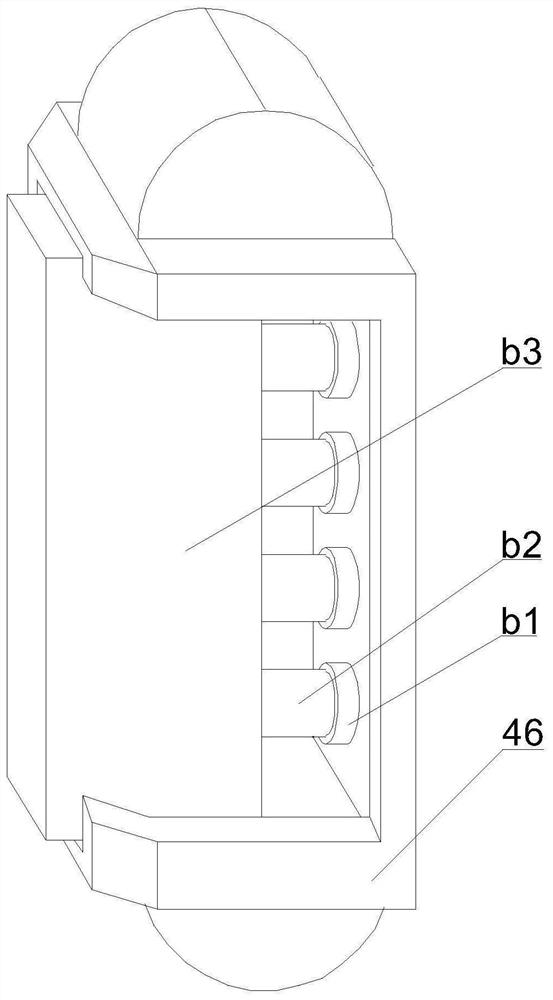

[0047] Such as Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the safety brake mechanism 46 includes a fixed housing 1, the inner wall of the fixed housing 1 is fixedly connected with a friction brake pad b3, and the outer surface of the friction brake pad b3 The support block b31 is fixedly connected to the surface, and the support block b31 is evenly distributed on the outer surface of the friction brake pad b3, and the support friction column b34 is fixedly connected to the outer surface of both sides of the support block b31, and the outer surface of the support block b31 is fixed Brake pads b32 are connected, and the brake pads b32 are evenly distributed on the outer surface of the support block b31, and the outer surface of the brake pad b32 is fixedly connected with support friction columns b34, and the brake pads b32 are arranged alternately on the outer surface of the support block b31 , there is a ...

Embodiment 3

[0049] Such as Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the pushing and fixing mechanism 44 includes a fixed casing two, and the outer surfaces of both ends of the fixed casing two are fixedly connected with a semicircular fixed head a1, and the fixed casing two A weightless push module a2 is fixedly installed inside, a push block a3 is movably connected to the left outer surface of the fixed shell 2, and an extension clamping column a4 is fixedly connected to the left outer surface of the push block a3, and the extension clamping column a4 is evenly connected Distributed on the outer surface of the push block a3, a hollow fixed cylinder b1 is fixedly connected to the outer surface of the fixed shell one, and one end of the hollow fixed cylinder b1 penetrates from the right outer surface of the fixed shell one to the left inner surface, and is hollowly fixed The inside of the barrel b1 is movably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com