Horizontal well close cutting fracturing crack propagation prediction and design parameter optimization method

A technology of fracture propagation and design parameters, applied in design optimization/simulation, calculation, earthwork drilling, etc., which can solve the problem of inability to accurately predict the fracture propagation trajectory of horizontal well density cutting fracturing, the influence of natural fractures, and the inter-fracture stress interference fracture separation. Crossing and intersection, complex flow distribution, fracturing fluid compound filtration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. The following detailed descriptions of the embodiments of the present invention provided in the accompanying drawings only represent the selection of the present invention Example.

[0021] Step S01, collecting formation parameters, construction parameters and well completion parameters required for fracturing construction design.

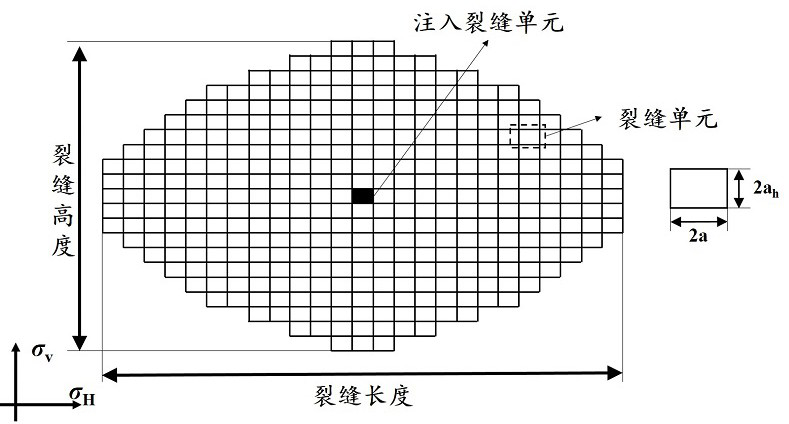

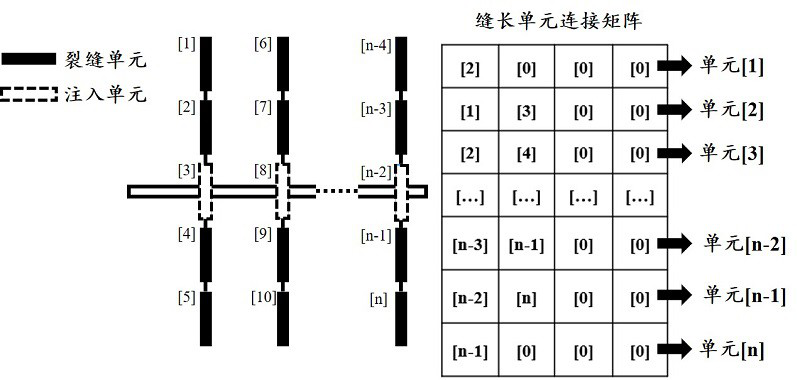

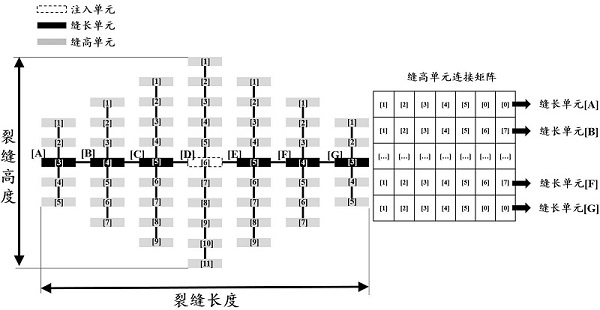

[0022] Specifically, formation parameters and construction parameters include: horizontal maximum principal stress, horizontal minimum principal stress, Young's modulus of reservoir rock, Poisson's ratio of reservoir rock, fracture toughness of reservoir rock, tensile strength of reservoir rock, reservoir rock Average thickness, fluid loss coefficient of reservoir matrix, stress difference between reservoir and caprock, stress difference b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com