Goaf coal spontaneous combustion partition isolation prevention method based on coal face advancing degree

A technology of coal mining face and prevention method, applied in the direction of dust prevention, mining equipment, mining equipment, etc., can solve the problems of fire, limited, limited effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

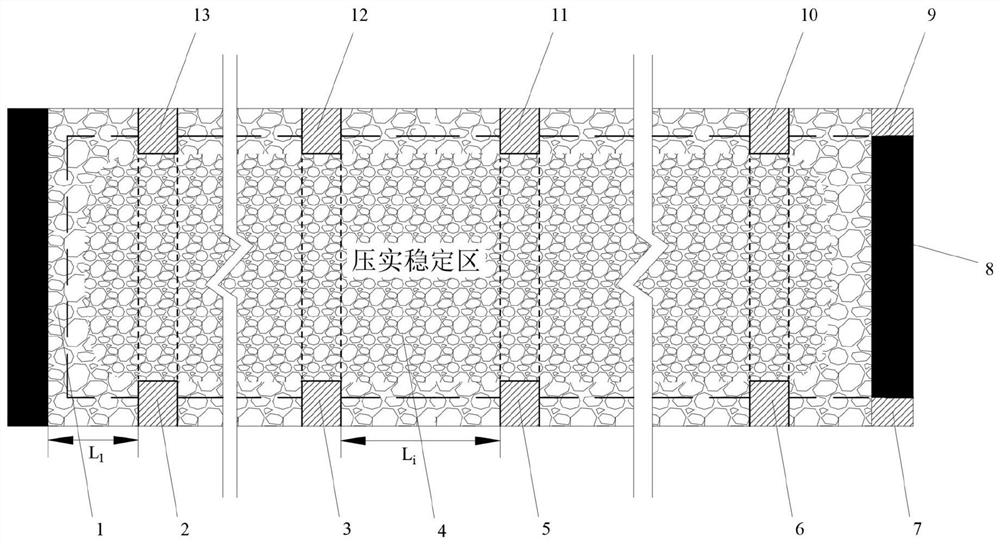

[0029] Step 1, such as figure 1 As shown, after the coal mining face is arranged, it is pushed forward by the cut hole 1 L 1 After m, the flexible formwork is hung on the goaf side of the end of the coal mining face and the goaf side of the lower end respectively, and fixed with anchor rods, and then micro-expansion concrete is poured into the flexible formwork for filling to form a filling body. After the filling body condenses, the first upper partition wall 13 and the first lower partition wall 2 are formed respectively, and the first upper partition wall 13 and the first lower partition wall 2 form the first partition wall. The coal working face continues to advance, and the first upper isolation wall 13, the first lower isolation wall 2, and the collapsed and compacted coal rock mass in the corresponding goaf remaining coal compaction and stability zone 4 form a first isolation zone;

[0030] Step 2: The coal mining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com