Efficient energy-saving air compressor

An energy-saving, air compressor technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as inability to monitor working conditions, troublesome control operations, and prone to noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

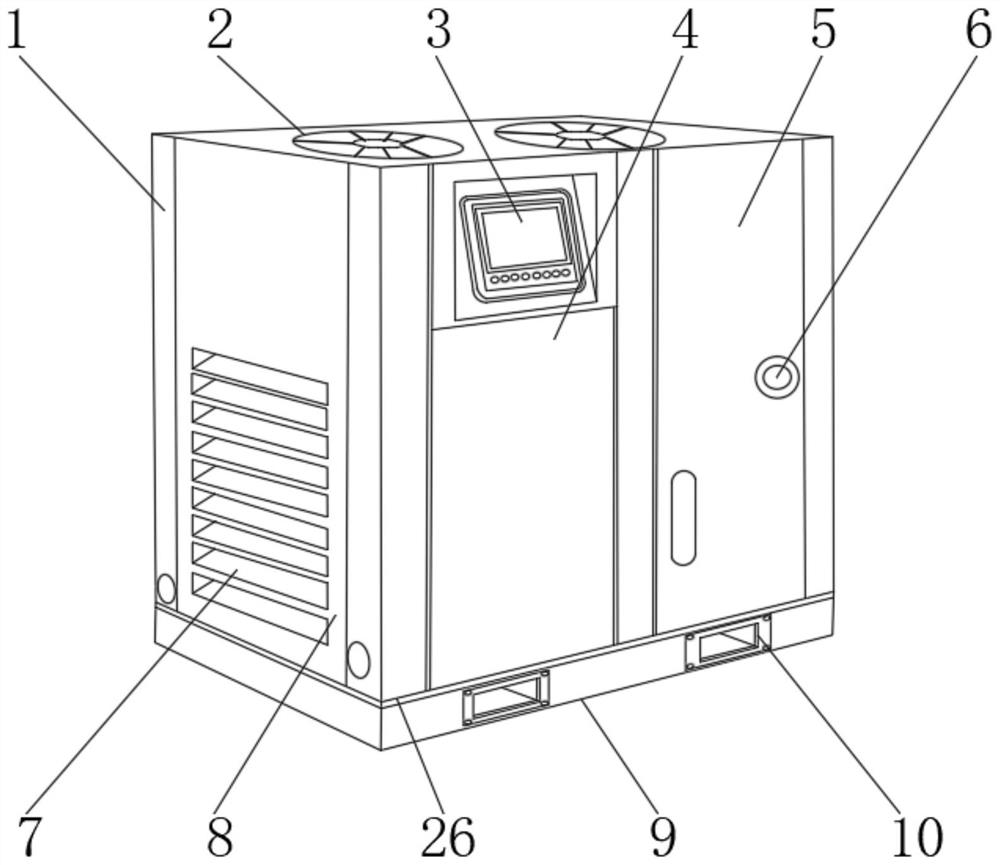

[0028] Such as Figure 1-4 As shown, a high-efficiency energy-saving air compressor includes a device main body 1, a positioning base 9 is installed on the bottom of the device main body 1, and a positioning connection seat 26 is fixedly connected between the device main body 1 and the positioning base 9. A control box 3, a motor box 4 and a compression chamber 5 are installed inside, an oil filling mechanism 6 is installed at the front end of the compression chamber 5, a cooling fan 2 is installed on the upper end of the device main body 1, and an inspection door 8 is installed outside the device main body 1.

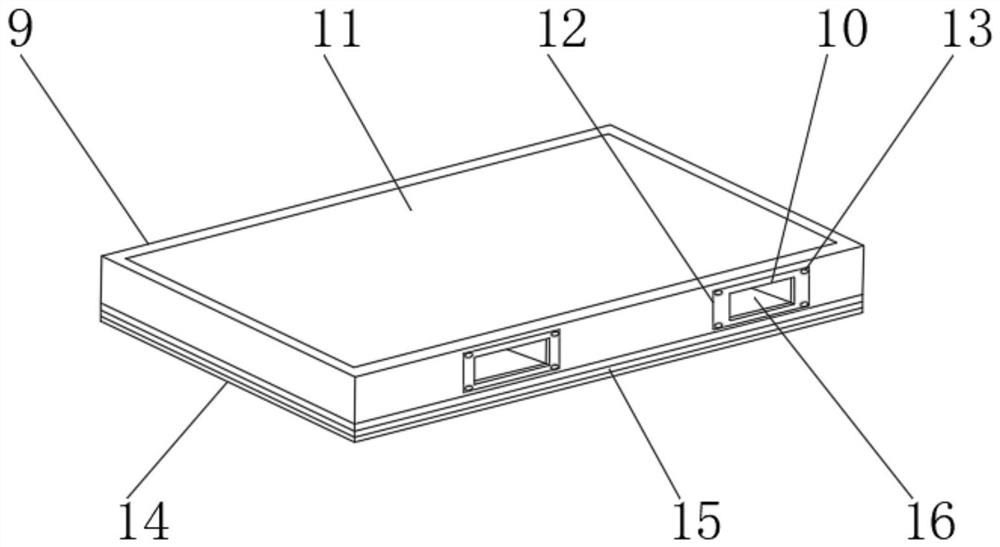

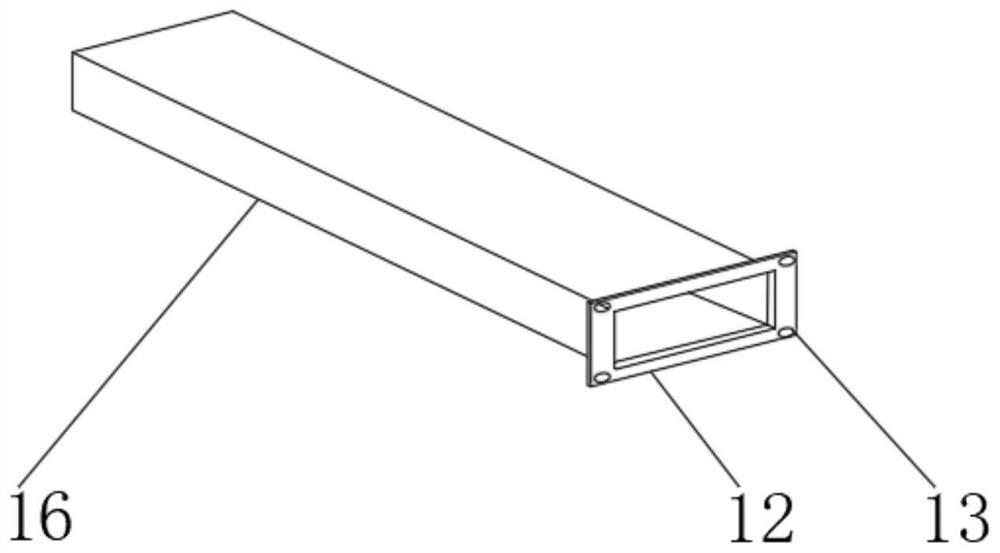

[0029] The outer surface of the upper end of the positioning base 9 is fixedly connected with a connection pad 11, the outer surface of the lower end of the positioning base 9 is fixedly connected with a shock absorber 14, the inside of the shock absorber 14 is fixedly connected with a moisture-proof bottom pad 15, and the inside of the positioning base 9 is provided with...

Embodiment 2

[0033] On the basis of Example 1, as figure 1 , 5 As shown, a high-efficiency energy-saving air compressor includes a device main body 1, a positioning base 9 is installed on the bottom of the device main body 1, and a positioning connection seat 26 is fixedly connected between the device main body 1 and the positioning base 9. A control box 3, a motor box 4 and a compression chamber 5 are installed inside, an oil filling mechanism 6 is installed at the front end of the compression chamber 5, a cooling fan 2 is installed on the upper end of the device main body 1, and an inspection door 8 is installed outside the device main body 1.

[0034] The middle part of the inspection door 8 is equipped with a cooling seat 7, and the front end of the inspection door 8 is equipped with a handle 18 and an adjustment member 20. The outer surface of the inspection door 8 is fixedly connected with a sound-absorbing pad 19, and the outer side of the inspection door 8 is provided with a chute ...

Embodiment 3

[0037] On the basis of Example 2, such as figure 1 , 6 As shown, a high-efficiency energy-saving air compressor includes a device main body 1, a positioning base 9 is installed on the bottom of the device main body 1, and a positioning connection seat 26 is fixedly connected between the device main body 1 and the positioning base 9. A control box 3, a motor box 4 and a compression chamber 5 are installed inside, an oil filling mechanism 6 is installed at the front end of the compression chamber 5, a cooling fan 2 is installed on the upper end of the device main body 1, and an inspection door 8 is installed outside the device main body 1.

[0038] The interior of the control box 3 is provided with an air monitoring sensor module, a pressure monitoring sensor module, a screw speed monitoring sensor module, an rs485 serial port communication module, a PLC intelligent control module, a power supply module, a display module and a working state control module, and an rs485 serial po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com