A kind of municipal drainage pipeline construction technology

A technology for pipeline construction and municipal drainage, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as disturbance of concrete pipes, water leakage at joints, cracking of cement mortar, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

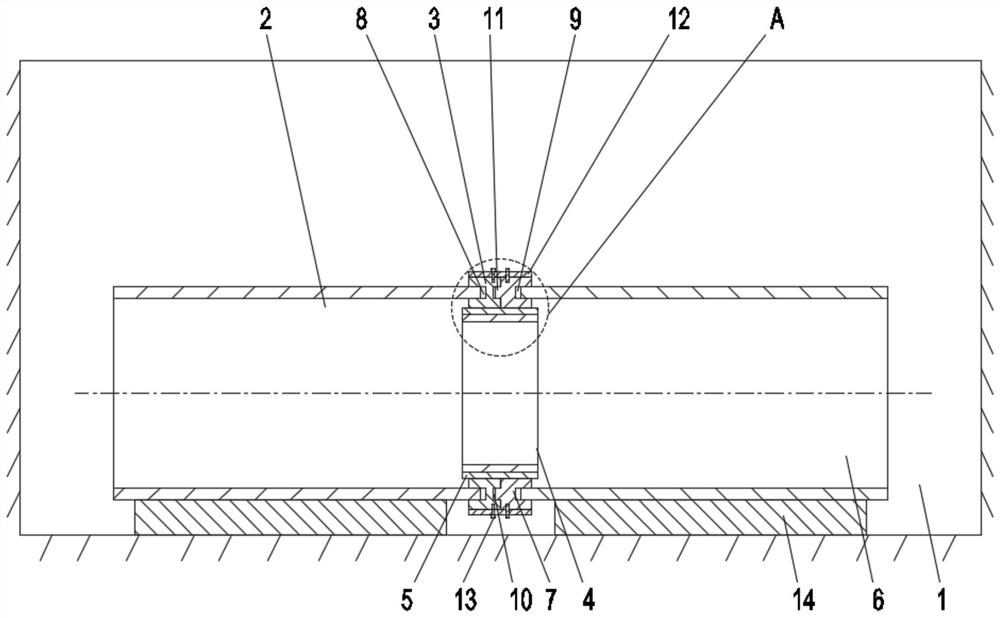

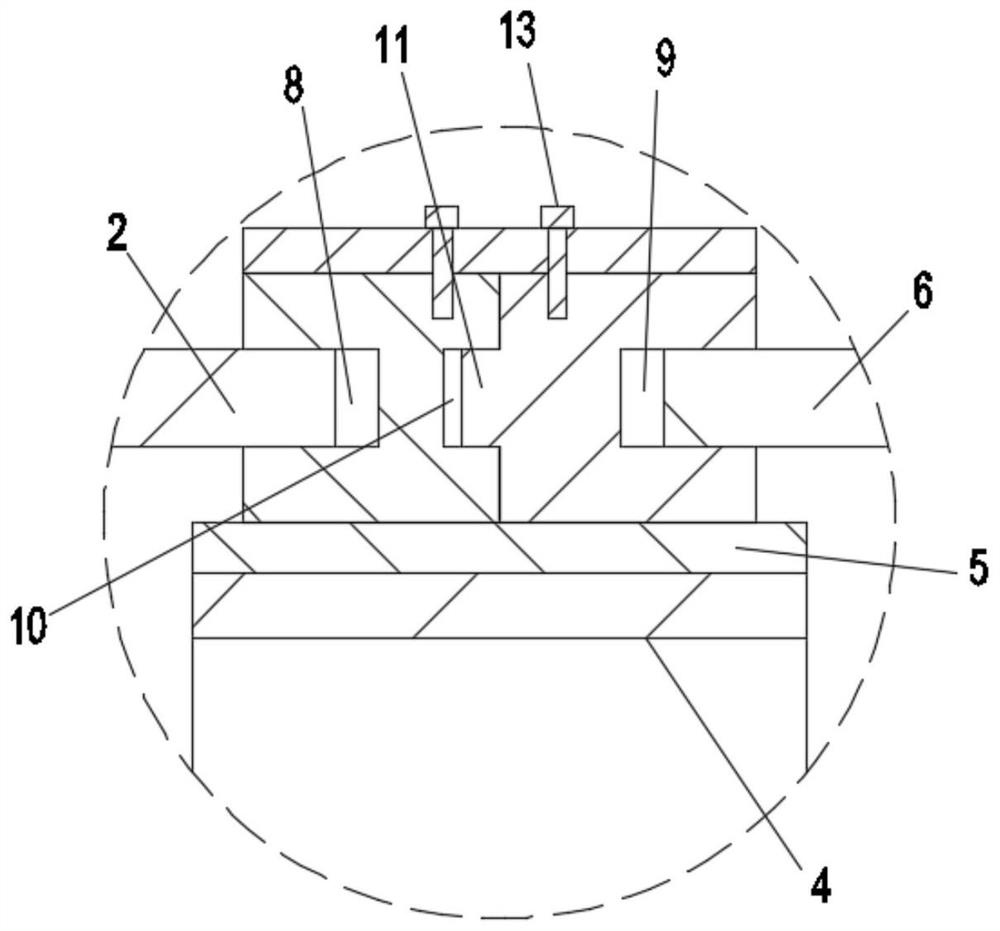

[0022] The technical solutions in the present invention will be further described below with reference to the accompanying drawings and embodiments.

[0023] like figure 1 and figure 2 As shown, a municipal drainage pipeline construction process includes the following steps:

[0024] S1. Excavate the trench 1 according to the design requirements, remove the debris and floating soil in the trench 1, compact the foundation at the bottom of the trench 1 and level the foundation;

[0025] S2. Place the first concrete pipe 2 in the groove 1, and clamp the first elastic sealing ring 3 at the end of the first concrete pipe 2 along the circumferential direction of the end. The upper edge of the first sealing ring 3 is A first clamping groove 8 is opened in the circumferential direction, the inner wall of the first clamping groove 8 is coated with adhesive, and the end of the first concrete pipe 2 is clamped and connected with the first clamping groove 8 and the two are sealed;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com