Lamp heat conduction arm and heat conduction method thereof

A technology of lamps and heat conducting sheets, which is applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., which can solve the problems of space occupation, cumbersome disassembly and assembly of profile radiators, large installation positions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

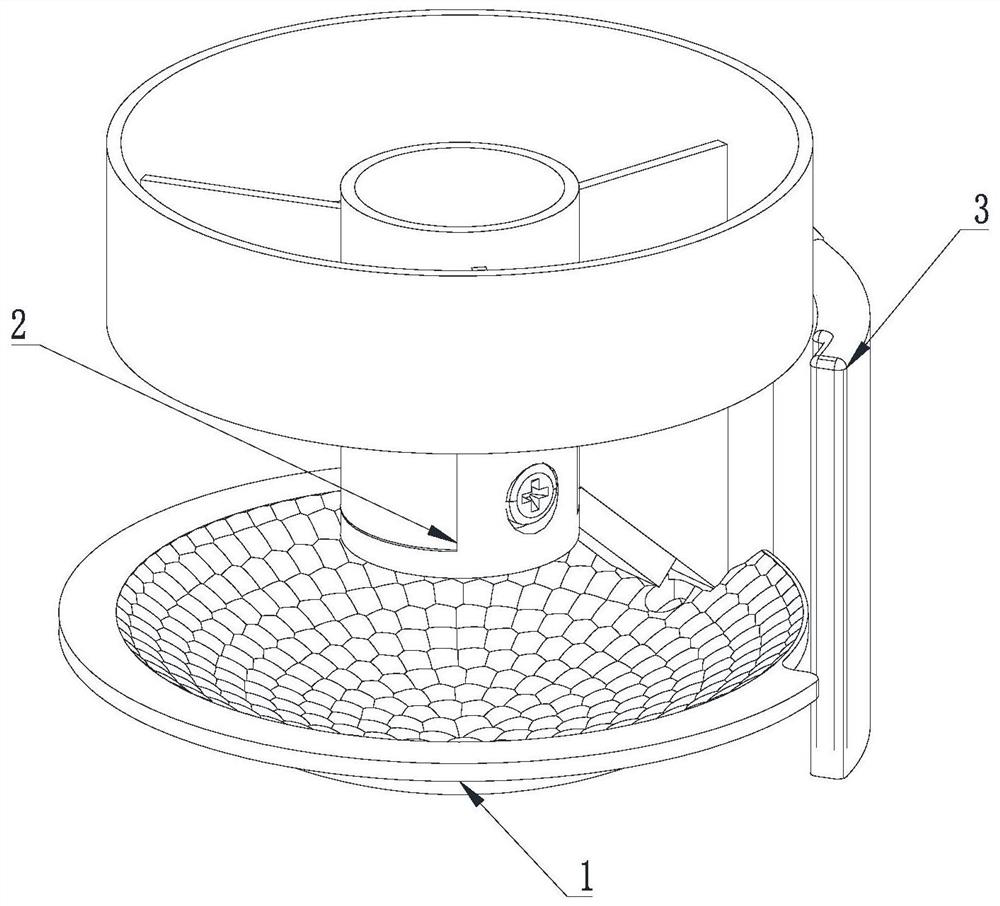

[0124] like Figure 1 ~ 2 As shown, a luminaire thermally conductive arm extends by a light source to the side surface of the lamp to achieve lateral extension heat.

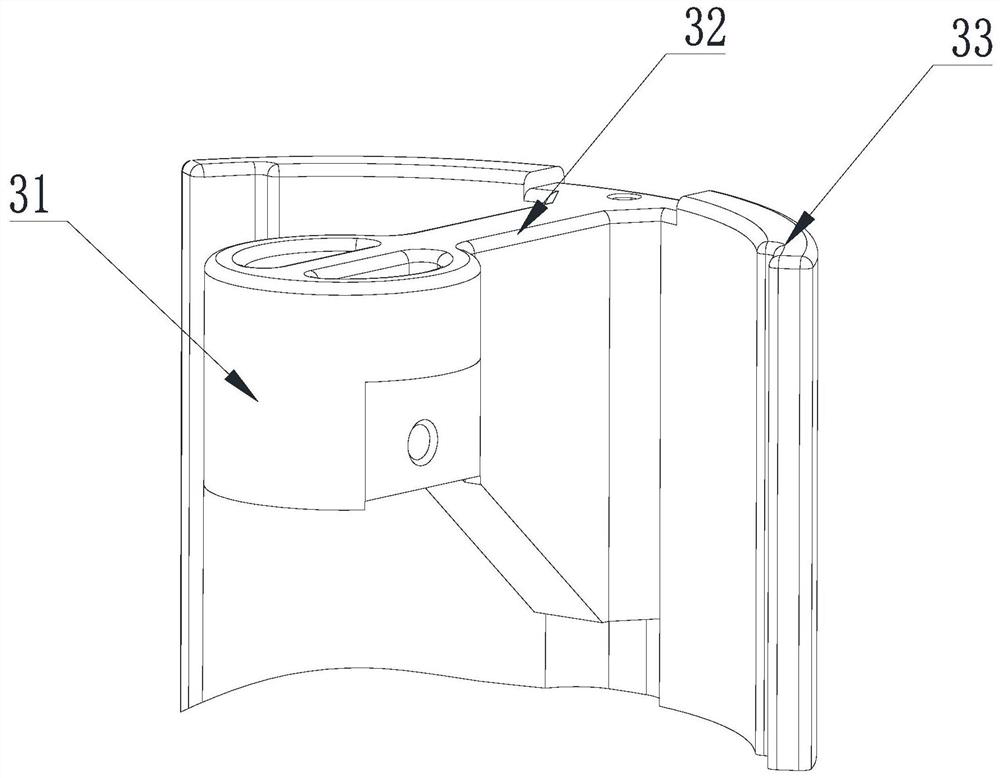

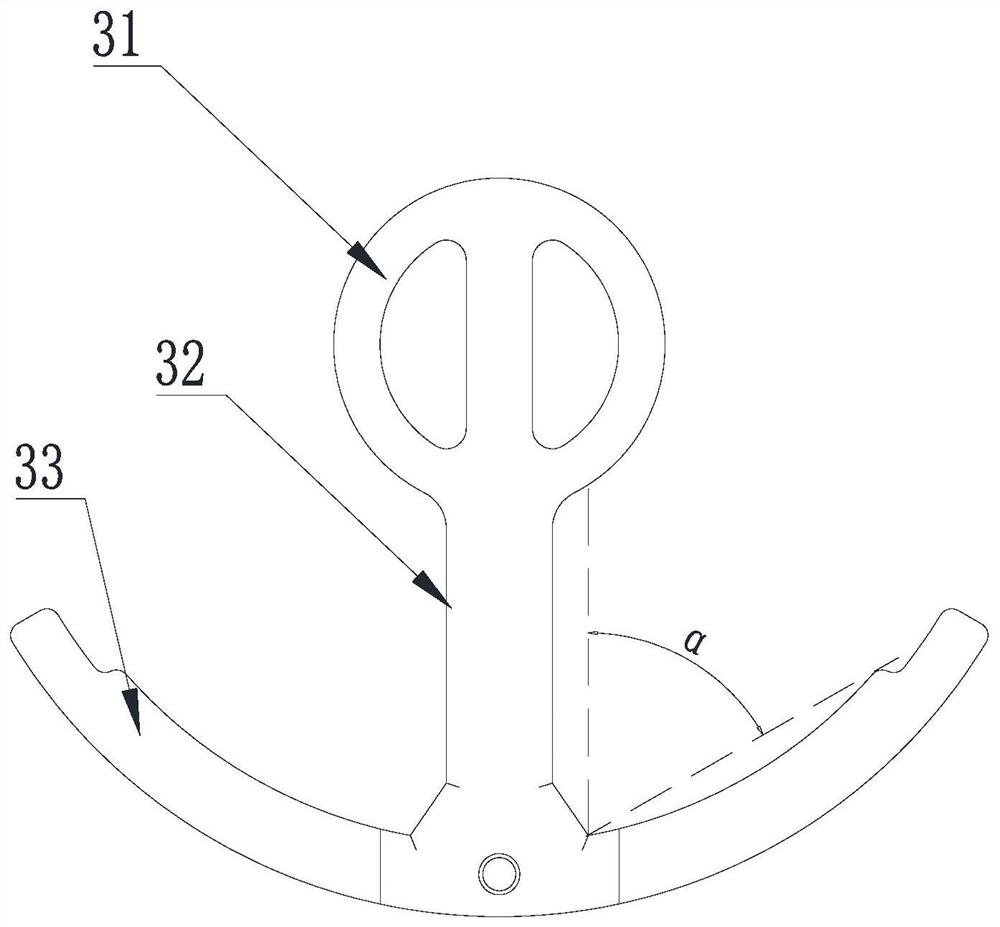

[0125] Further, the heat transfer arm 3 includes a thermally conductive end portion 31 and a thermally conductive extension portion 32 extending from the guiding end portion 31, the thermal extension portion 32 near the passage of the heat transfer end portion 31 is proximally, away from the heat conductive end portion 31 end For the distal end, the heat arm 3 further includes a heat conductive sheet 33 that extends from the distal ends of the heat transfer extension portion 32.

[0126] Further, the heat transfer sheet 33 is a circular thermally conductive sheet 33 or an arcuate thermally conductive sheet 33 or a rectangular thermally conductive sheet 33.

[0127] Further, the heat transfer end portion 31 is hollow, and one end of the heat transfer extension portion 32 extends from one side of the heat conductive end ...

Embodiment 2

[0132] like figure 2 As shown, the present embodiment provides a mixing integrated module, including the reflector 1 and the light source assembly 2 disposed above the reflector 1, further comprising a thermally conductive arm 3 disposed over the light source assembly 2, the The heat transfer arm 3 extends laterally extending heat through the side surface of the upper direction mixing integrated module of the light source assembly 2.

[0133] Further, such as figure 1 As shown, the heat transfer arm 3 includes a thermally conductive end portion 31 that is fixedly coupled to the light source assembly 2 and a thermally conductive extension portion 32 extending from the guiding end portion 31, the heat transfer extension portion 32 adjacent to the conductive end portion 31. The proximal end, away from the heat transfer end portion 31 is the distal end, and the heat transfer arm 3 further includes a heat transfer sheet 33 extending from the distal end of the heat transfer extension po...

Embodiment 3

[0151] The present embodiment differs from the first embodiment in that, as Figure 9 As shown, the heat transfer sheet is closed, so that the heat conducting end portion is placed in a circular space.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com