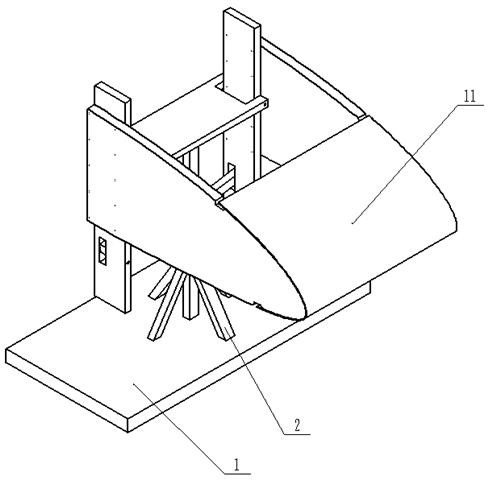

Front edge bending test tool and method

A bending test and leading edge technology, applied in the field of aircraft structure, can solve problems such as poor versatility, inconsistent with real working conditions, and unintuitive test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

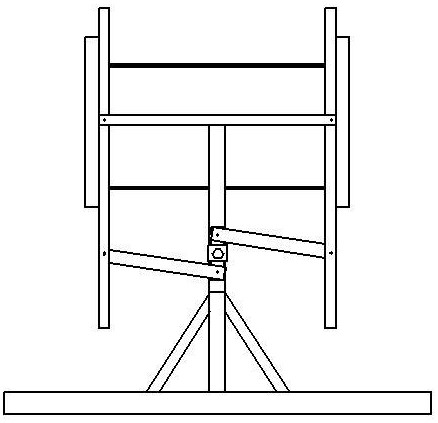

Examples

Embodiment

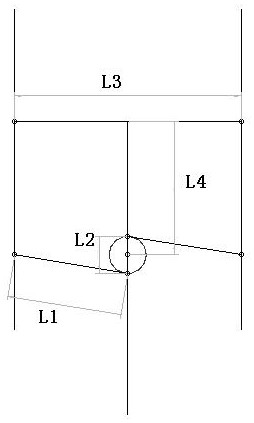

[0090] 1. The design method of the leading edge bending test tooling, the steps are as follows:

[0091] 1) Determine the shape of the ribbed plate 10 according to the cross-sectional shape of the front edge. When the front edge is a structure with a gradual change in cross-section, the shapes of the two ribbed plates 10 can be different;

[0092] 2) Determine the distance of the riser according to the length of the leading edge;

[0093] 3) According to the deformation requirements, determine the size and relative position of the long rotating rod and the short rotating rod through the calculation of the schematic diagram;

[0094] 4) Determine the torque wrench to be selected according to the size of the load, and determine the size of the hexagonal side of the loading end 7 according to the specifications of the torque wrench socket, and determine the size of the square side of the loading end 7 according to the size of the short rotating rod. It is also possible to make m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com