A method and device for measuring the rotational speed of an aero-engine

An aero-engine and rotational speed measurement technology, which is applied to measurement devices, engine testing, devices using electrical/magnetic methods, etc. Robustness and stability are improved, and the sensing accuracy is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

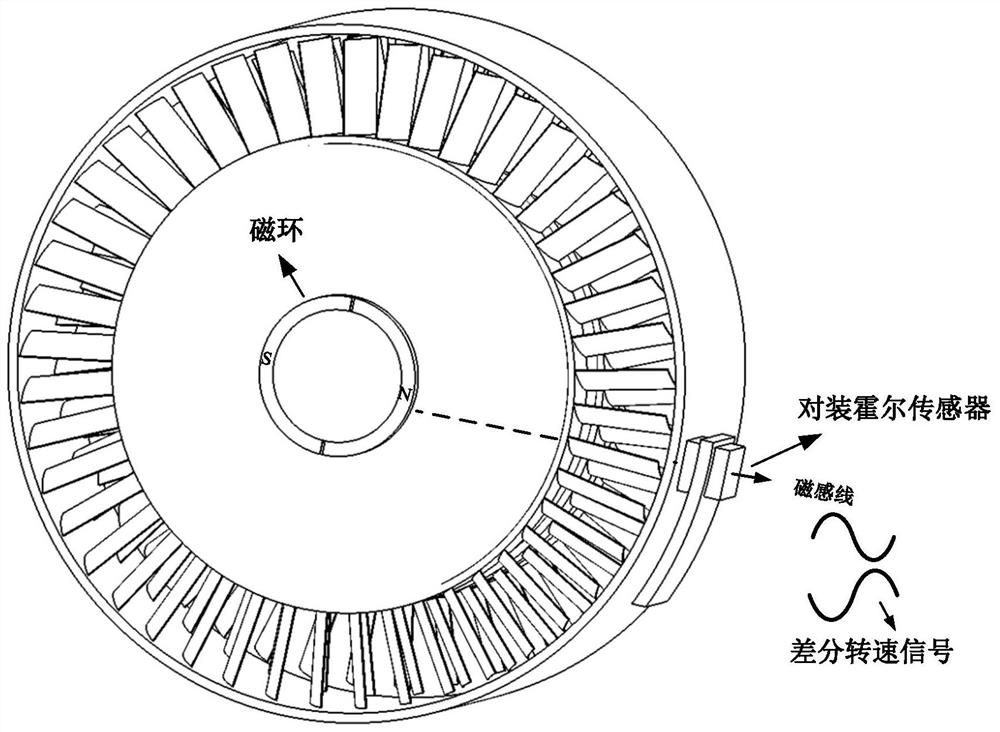

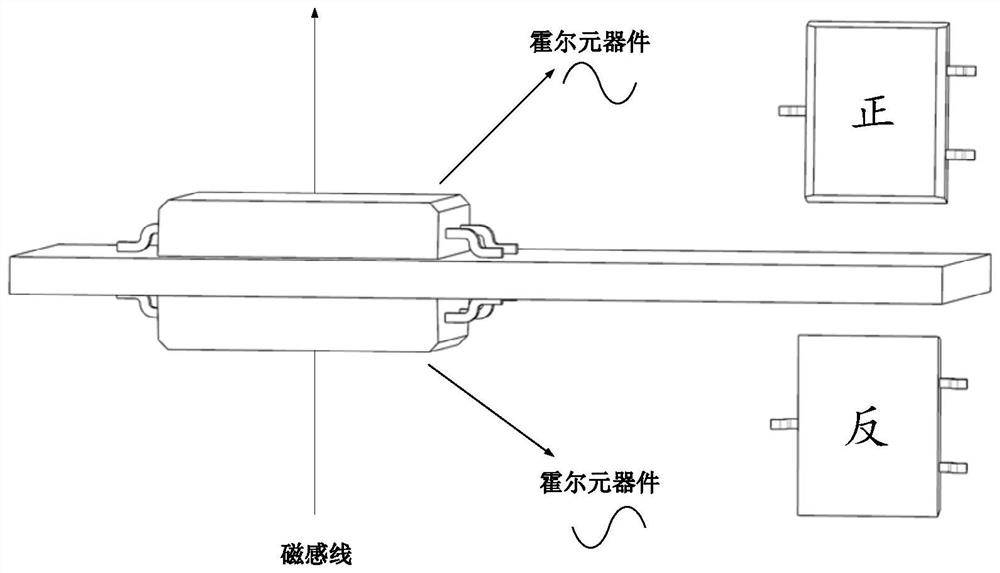

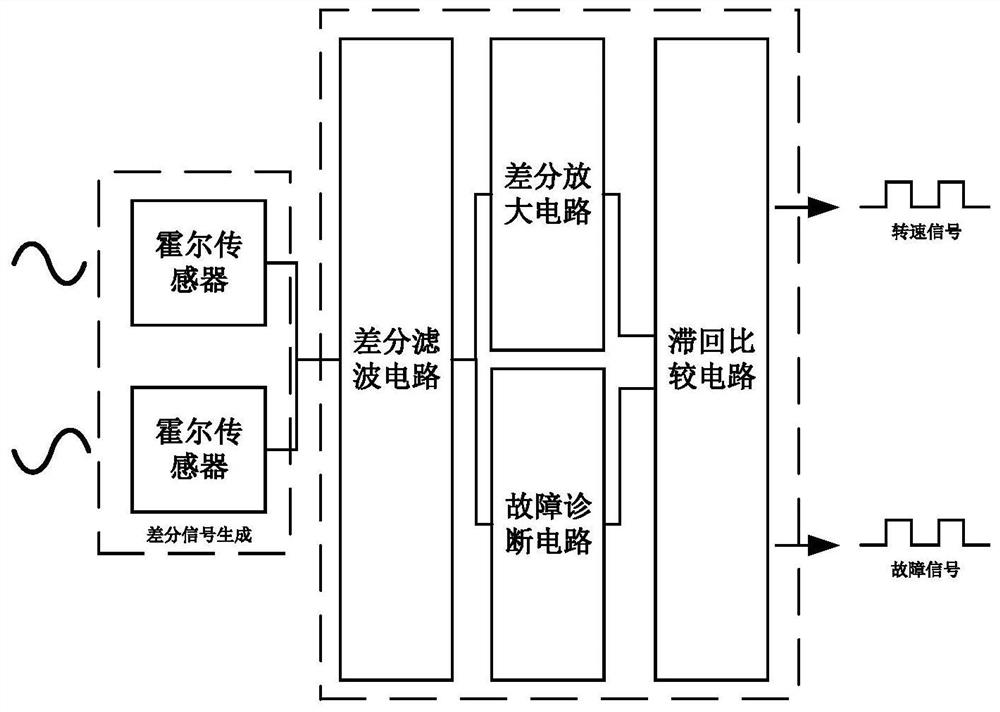

[0026] The working environment of aero-engine is harsh, such as high temperature, vibration, complex electromagnetic environment, etc. These problems will affect the speed measurement of aero-engine, and for the signal with weak amplitude such as the speed signal, these external noise interference will be directly superimposed On the original signal, the original signal is submerged in the noise signal; and these external noise signals often exist in the form of differential mode signals, and it is necessary to suppress this differential mode noise by generating a differential speed signal; However, when a single Hall sensor or a differential Hall sensor is used for speed acquisition in the traditional way, the amplitude of the generated speed signal is small and it is easily disturbed by environmental noise. The impact is also becoming more and more serious, which has an immeasurable impact on the control of the aero-engine. Moreover, due to the limitation of the signal acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com