Multi-torque integrated loading device for spline hub detection equipment

A technology for testing equipment and loading devices, which is applied in measuring devices, testing material strength by applying repetitive force/pulsation force, testing mechanical parts, etc. It can solve the problems of time-consuming and labor-intensive, low detection repeatability, low detection efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

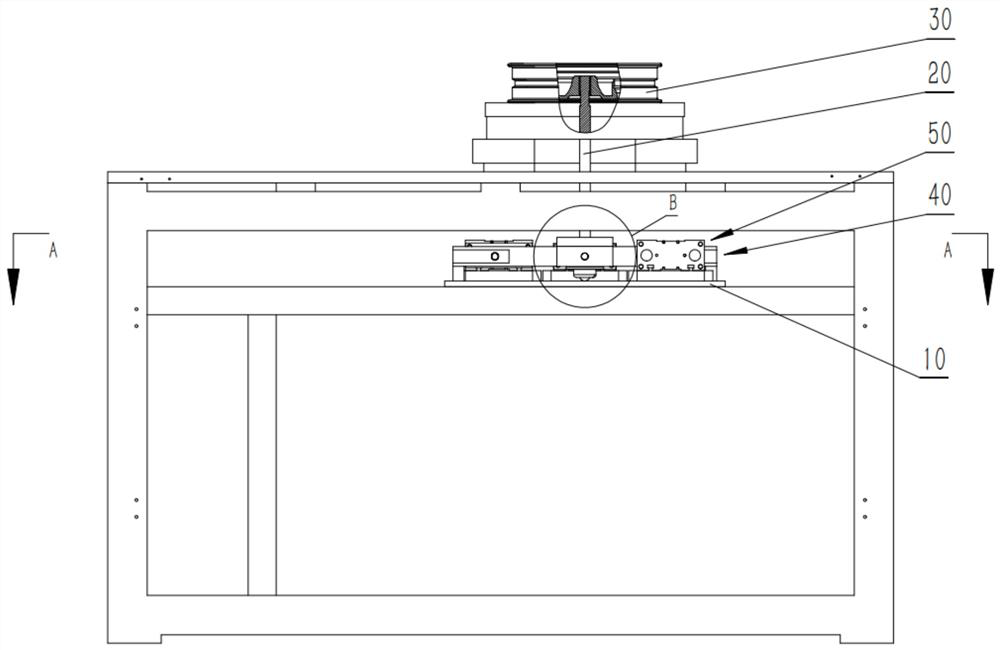

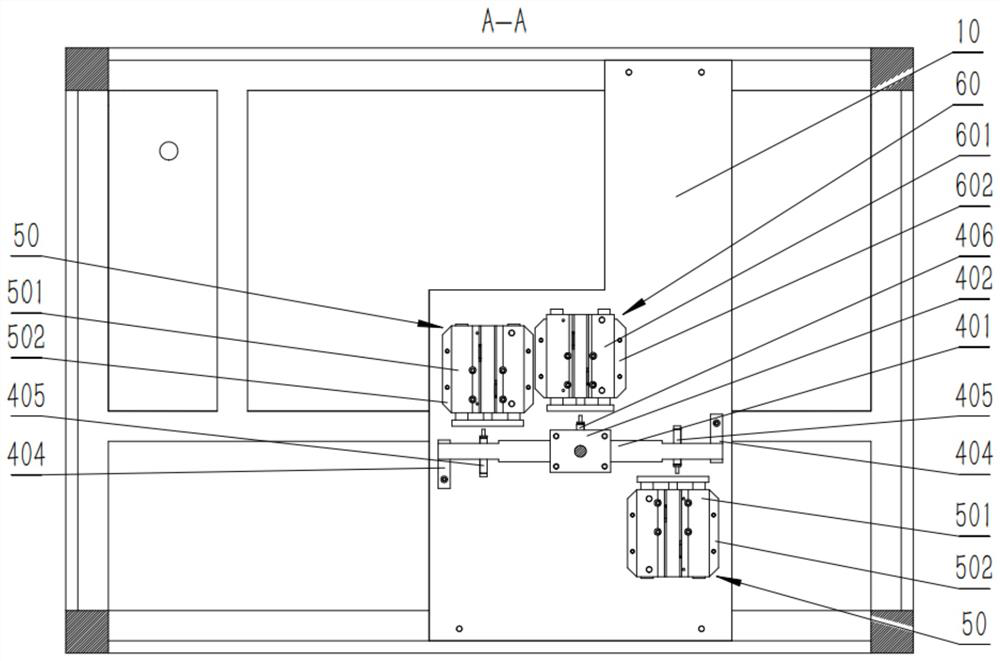

[0020] Such as Figures 1 to 6 As shown, a multi-moment integrated loading device of the present invention includes a worktable 10, and also includes a test bar assembly 40, a torsional loading assembly 50, a swing loading assembly 60 and a spline shaft 20 arranged on the worktable 10; One direction is Figure 4 The middle Z-axis direction, which is perpendicular to the worktable surface 10; the second direction is Figure 4 In the X-axis direction, it is parallel to the working surface 10 .

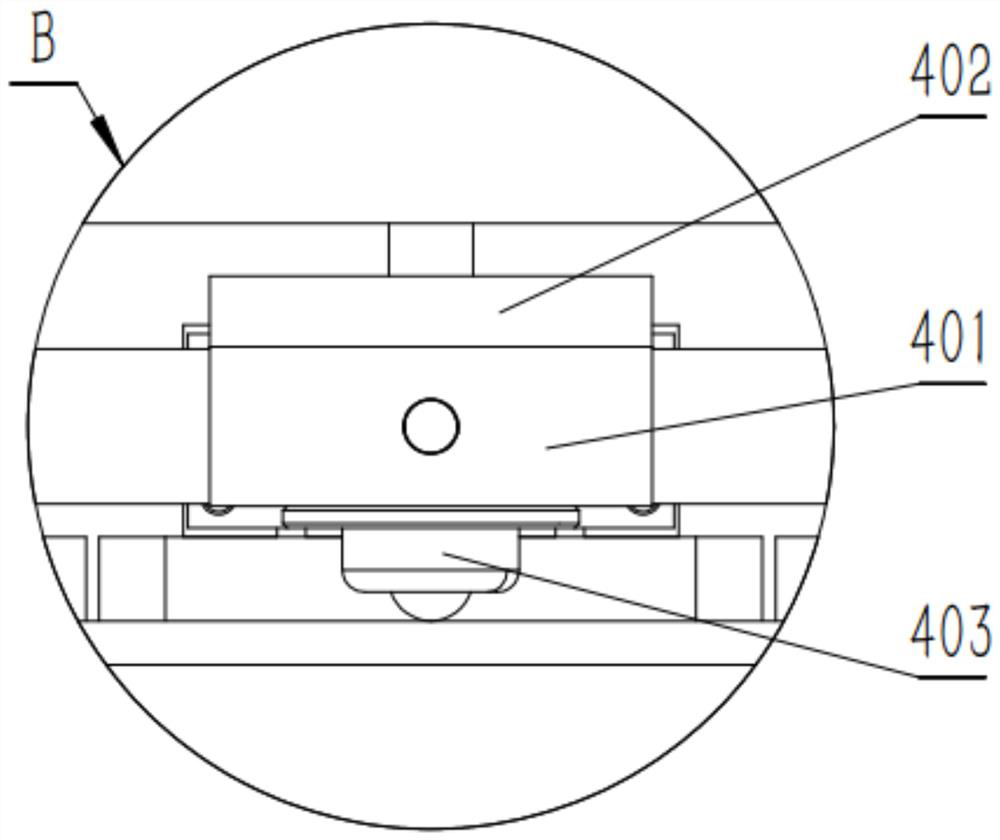

[0021] One end of the spline shaft 20 is a spline, and the other end is square; the middle part of the test bar 401 is in the shape of a cuboid; the spline shaft pad 402 is fixed on the upper side of the middle cuboid part of the test bar 401 through bolt connection, and the center of the spline shaft pad 402 is There is a square hole, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com