Low constant-force disc spring support hanger

A support hanger and disc spring technology, which is applied in the hanger field, can solve problems such as project design and construction impact, and achieve the effects of simple structure, wide application range, and reduced types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

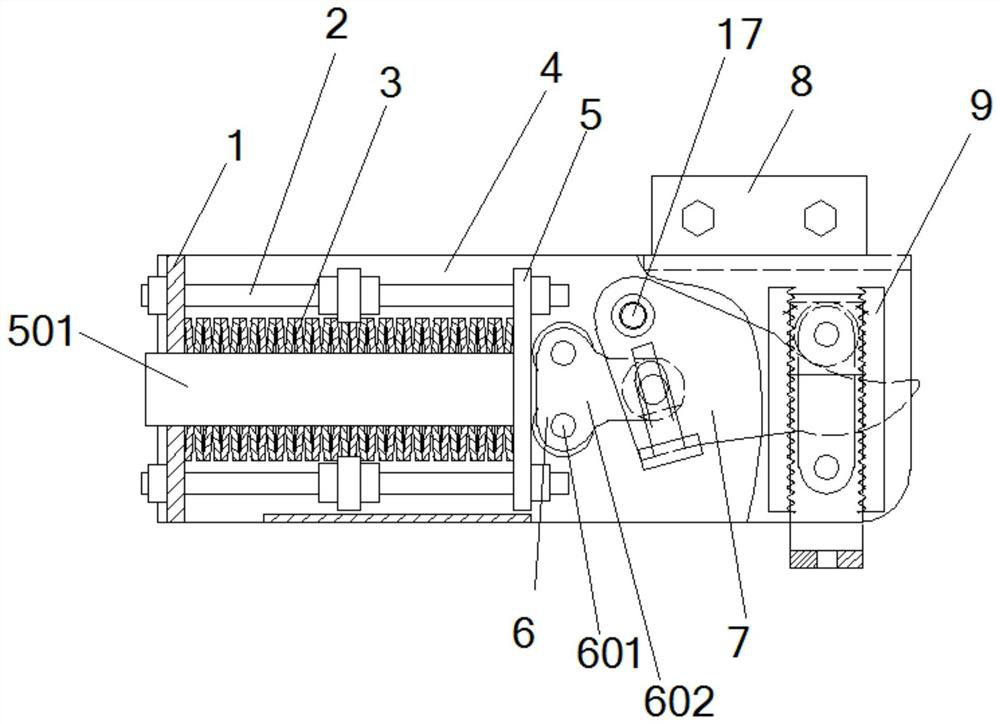

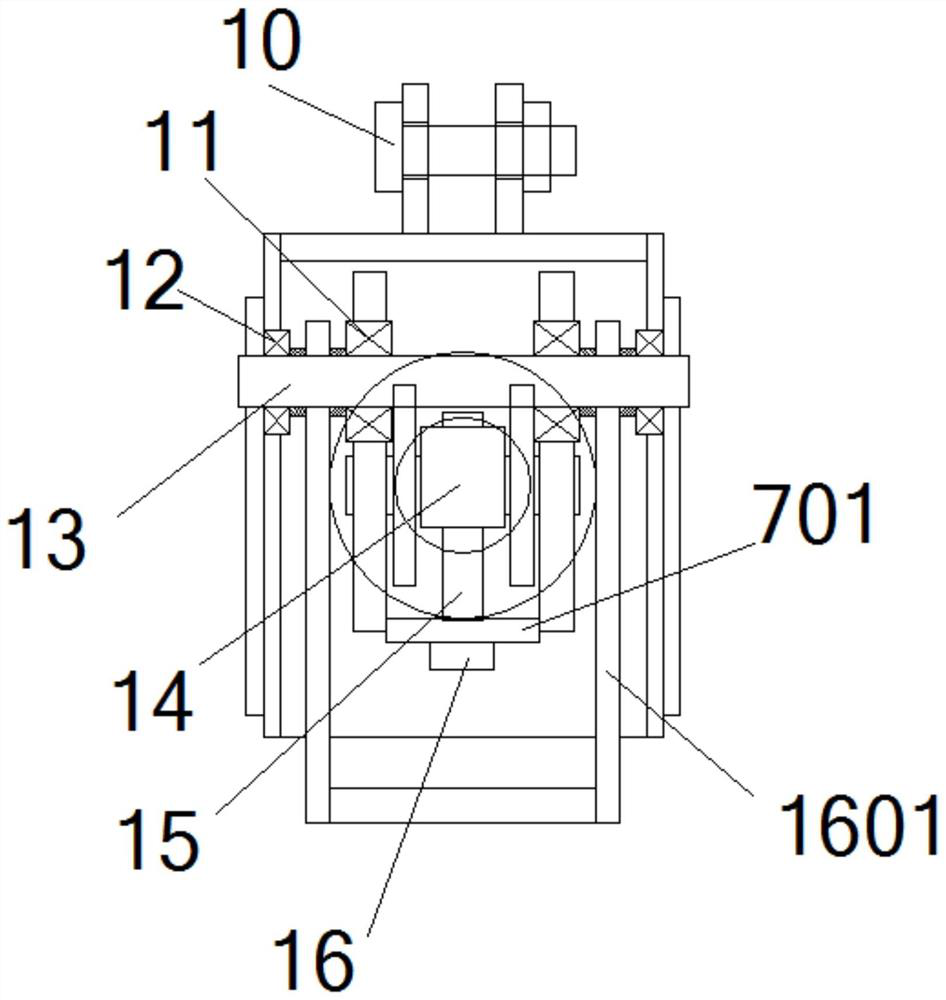

[0015] Embodiment 1: as figure 1 , 2 As shown, the present embodiment provides a low profile constant force disc spring support and hanger, including a fixed frame 4, a disc spring structure, a pressure roller assembly 6 corresponding to the disc spring structure, and a pressure roller assembly 6 are arranged in the fixed frame 4. The slewing frame 7 connected with the roller assembly 6, the hoisting assembly corresponding to the slewing frame 7, and the locking plate 9 corresponding to the hoisting assembly, the slewing frame 7 is hinged to the fixed frame 4 through the main shaft 17, and the pressing roller assembly 6 includes pressing rollers 601. Install the pressure roller plate 602 of the pressure roller. The pressure roller plate 602 is hinged with the rotary frame 7 through the adjustment shaft 14. The disc spring structure includes the disc spring rear pressure plate 1 and the disc spring front pressure plate 5 corresponding to the pressure roller 601. , the disc spr...

Embodiment 2

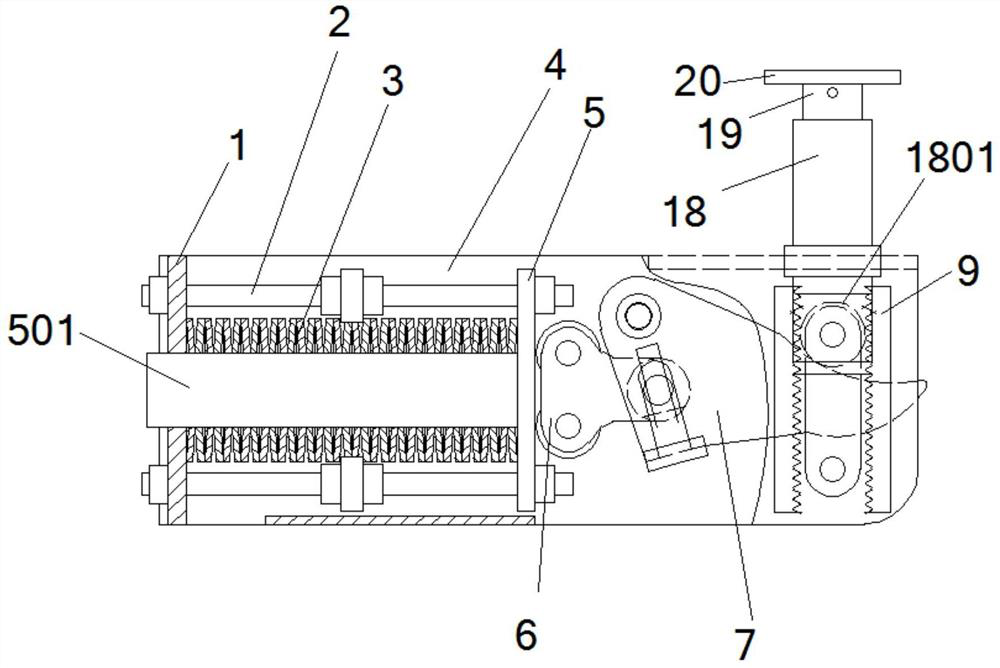

[0017] Embodiment 2: as image 3 , 4 A low-profile constant force disc spring support and hanger, including a fixed frame 4, a disc spring structure, a pressure roller assembly 6 corresponding to the disc spring structure, and a rotary frame connected to the pressure roller assembly 6 are arranged in the fixed frame 4 7. The support assembly corresponding to the revolving frame 7 and the locking plate 9 corresponding to the hoisting assembly, the revolving frame 7 is hinged to the fixed frame 4 through the main shaft 17, the pressure roller assembly 6 includes a pressure roller 601, a pressure roller for installing the pressure roller Roller plate 602, the pressure roller plate 602 is hinged with the rotary frame 7 through the adjustment shaft 14, the disc spring structure includes a disc spring rear pressure plate 1, a disc spring front pressure plate 5 corresponding to the pressure roller 601, and the disc spring rear pressure plate 1. The disc spring front pressure plate 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com