A Vacuum Lost Foam Valve Casting Process with Inorganic Machining

A technology of vacuum lost foam and casting process, applied in manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problem of different effects, and achieve the effect of simplifying the construction process, saving site labor, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the drawings and specific embodiments. The following embodiments are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

[0028] An inorganic processing vacuum lost foam valve casting process,

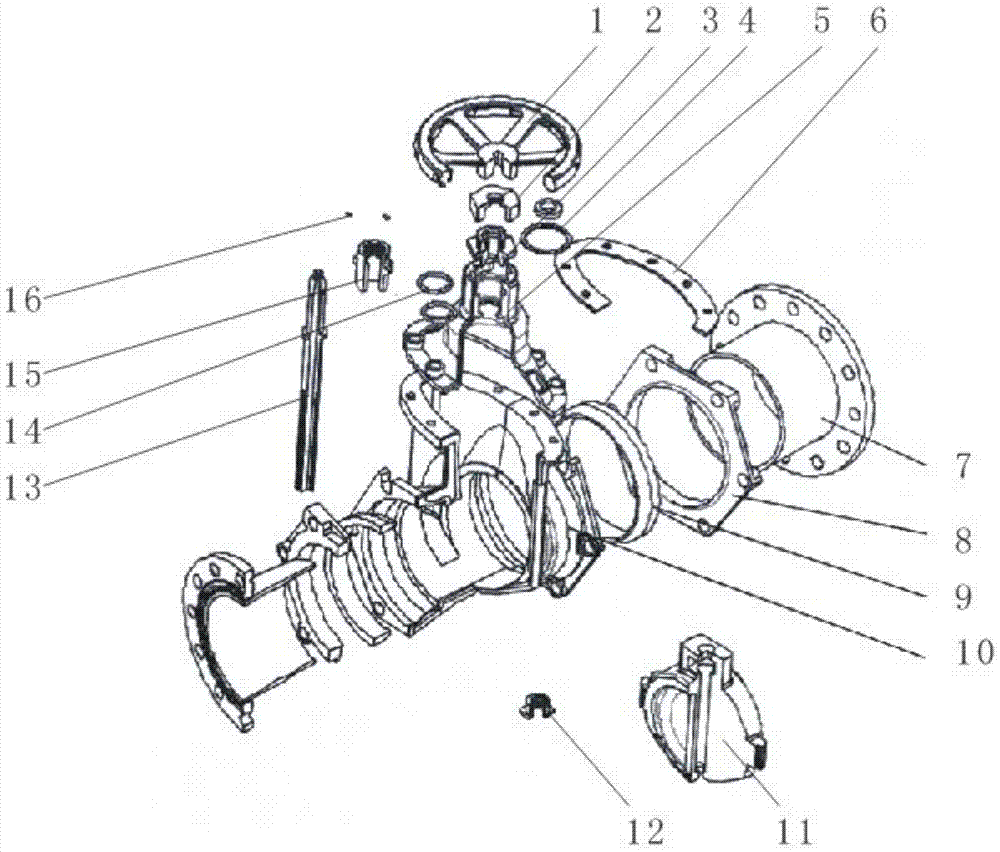

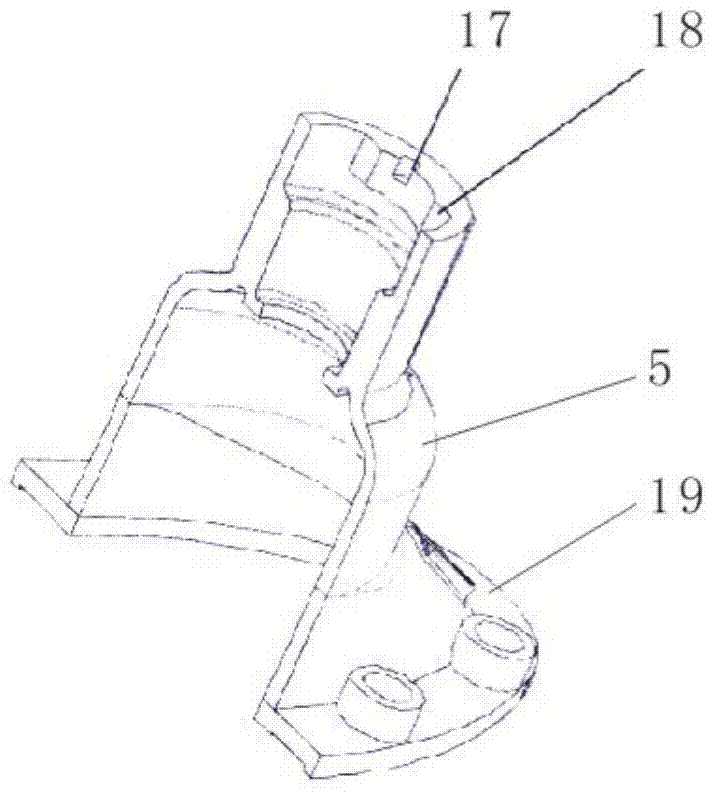

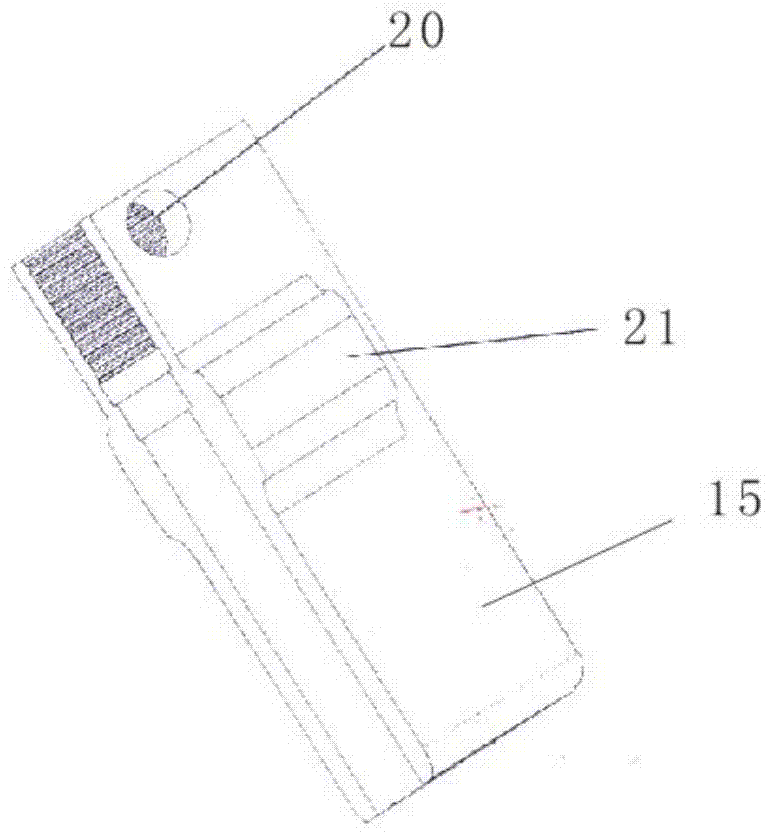

[0029] For the specific structure of the valve made in this embodiment, please refer to the accompanying drawings in the specification, and it is attached for ease of description. figure 1 In the direction shown in the illustration, the upper end of the valve body 10 is sealed and fixed with a valve cover 5, and a transversely through flow channel is formed in the valve body. A gate 11 for blocking the flow channel is guided and installed in the middle of the valve body. The upper end is fixedly mounted with a valve stem 13 through the gate female 12, the valve stem extends upwards from the valve cover, and a hand wheel 1 is installed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com