Transmission thermal sprocket chain plate tensioning hydraulic device

A technology of hydraulic device and wheel chain, applied in the direction of transmission device, friction transmission device, transmission device parts, etc., can solve the problems of easy change of upper and lower rail clearance, inability to perform online real-time adjustment, etc., to increase heat transfer coefficient and enhance heat dissipation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific embodiments.

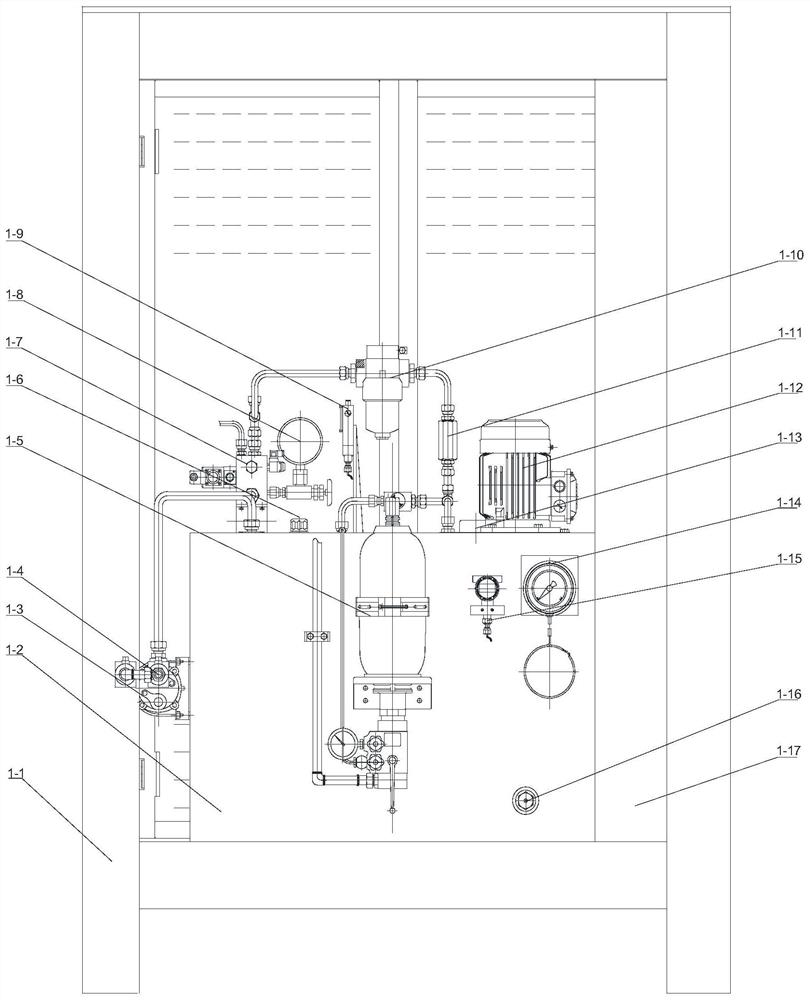

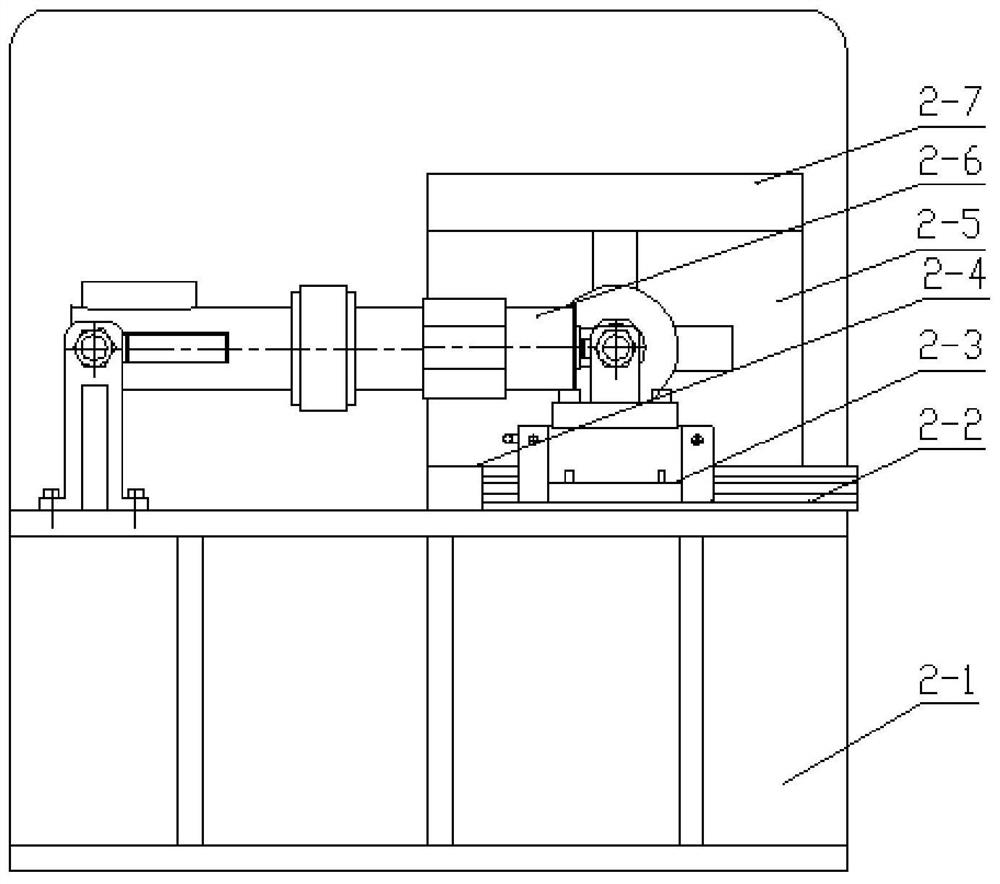

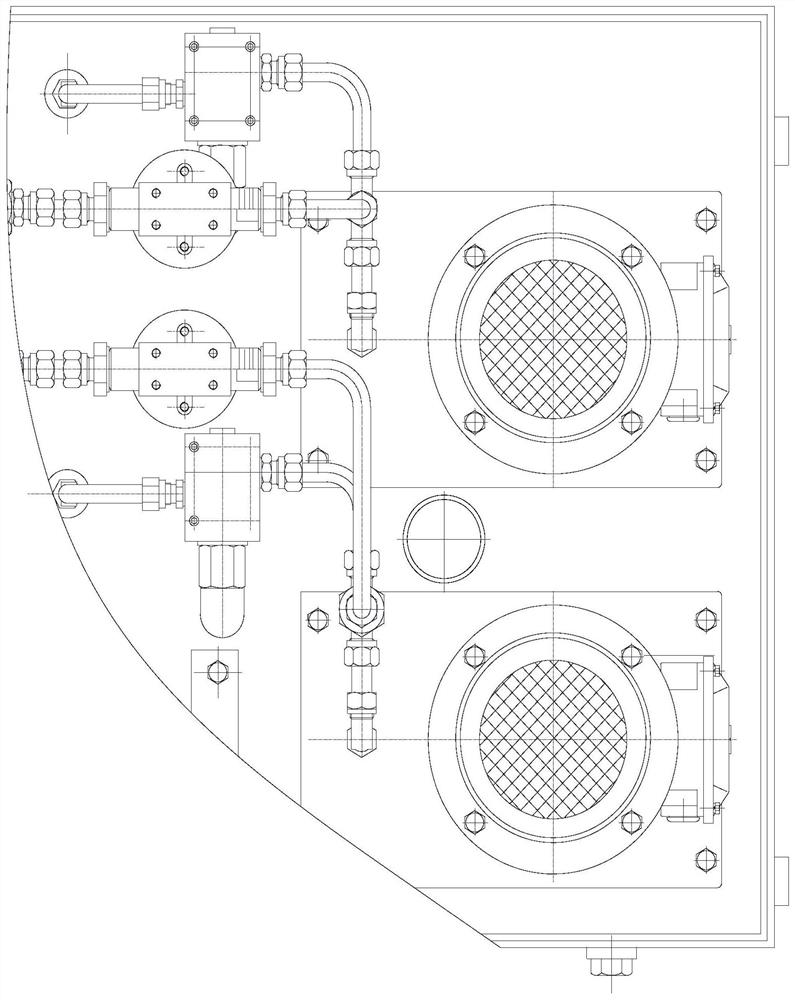

[0035] Such as figure 1 and figure 2 As shown, the present invention includes a protective outer frame 1-1, an oil tank 1-2, an automatic temperature control system, a control system, a hydraulic power system, a hydraulic control system, and an oil cylinder assembly. The protective outer frame 1-1 is a rectangular steel pipe and a steel plate weldment, and doors are installed on the left, right, front, rear, and four sides, and vent holes are opened on the doors to protect the body; the fuel tank 1-2 is arranged in the protective outer frame 1-1, The automatic temperature control system, hydraulic power system, and hydraulic control system are arranged around the oil tank 1-2 and inside the protective outer frame 1-1; the control system is arranged in the electric control collection cabinet 1-17, and the electric control collection cabinet 1-17 is set In the protective o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com