Nondestructive detection device and detection method for barrel-shaped complex curved surface workpiece

A complex surface, non-destructive testing technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of vertical transillumination, the inability to realize the arbitrary surface position of complex curved workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

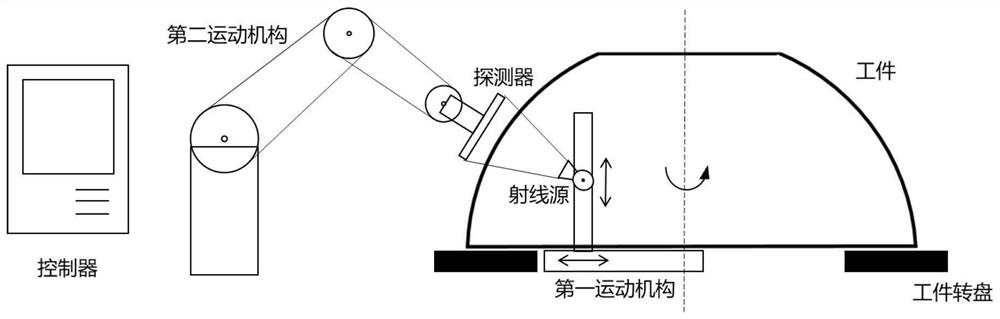

[0058] A specific embodiment of the present invention discloses a non-destructive testing device for barrel-shaped complex curved surface workpieces, such as figure 1 shown. The device includes: a detector, a ray source, a first motion mechanism, a second motion mechanism, a workpiece turntable, and a controller;

[0059] The workpiece turntable is a ring structure, and the workpiece to be detected is a barrel-shaped structure. The workpiece to be detected is placed on the workpiece turntable undercut, and the detection in the circumferential direction of the detected workpiece is realized through the rotation of the turntable;

[0060] The ray source adopts the way of directional radiation and is assembled on the first motion mechanism inside the detected workpiece;

[0061] Specifically, the first motion mechanism is a 3-degree-of-freedom motion mechanism, which can move in the horizontal direction and the vertical direction, and the pitch angle can be adjusted, so as to re...

Embodiment 2

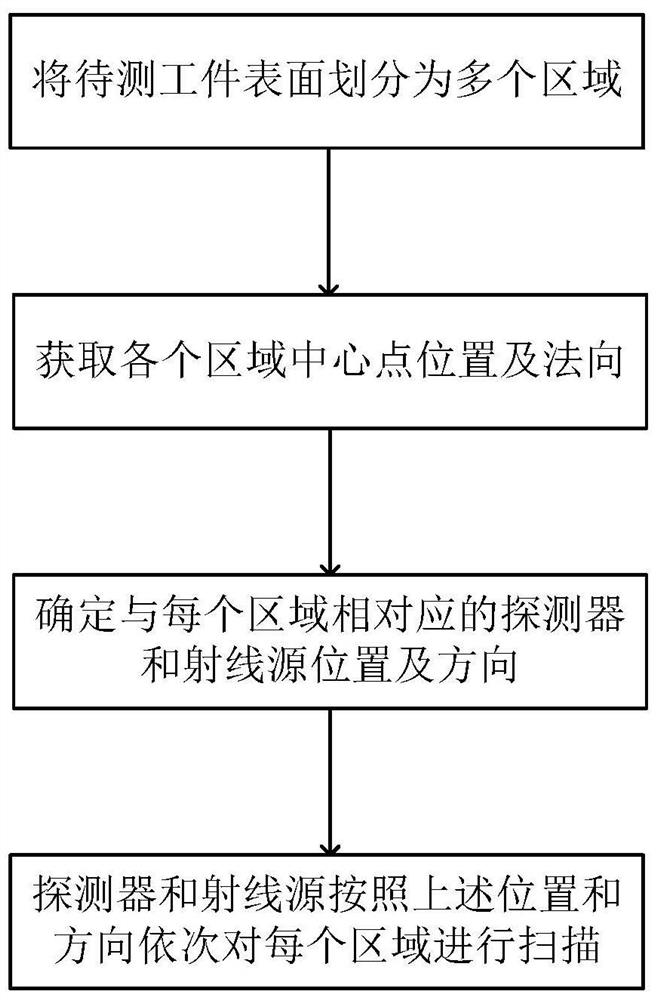

[0072] Another specific embodiment of the present invention discloses a method for non-destructive testing of barrel-shaped complex curved surface workpieces, such as figure 2 shown, including the following steps:

[0073] S1. Dividing the surface of the workpiece to be measured into multiple regions;

[0074] According to different workpiece inspection requirements, different area division methods can be used on the surface of the workpiece to be inspected.

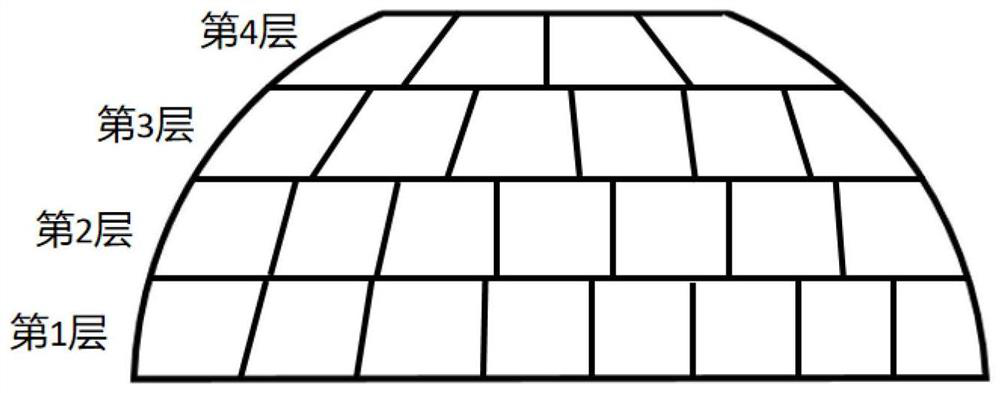

[0075] Since the imaging field of view of digital ray inspection is limited by factors such as the size of the detector plane, the radiation angle of rays, and the imaging magnification ratio, in order to meet the full coverage inspection of large-sized workpieces, it is necessary to perform partition inspection on the entire surface of the workpiece. The partition scheme is as follows: image 3 shown. According to the design of the motion scanning method of the present invention, the workpiece is first layered from b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com