Automatic mounting device for network cable crystal head

A network cable crystal head, automatic installation technology, applied in circuit/collector parts, electrical components, contact members with insulating cutting edges, etc., can solve the problems of high cost, error-prone, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

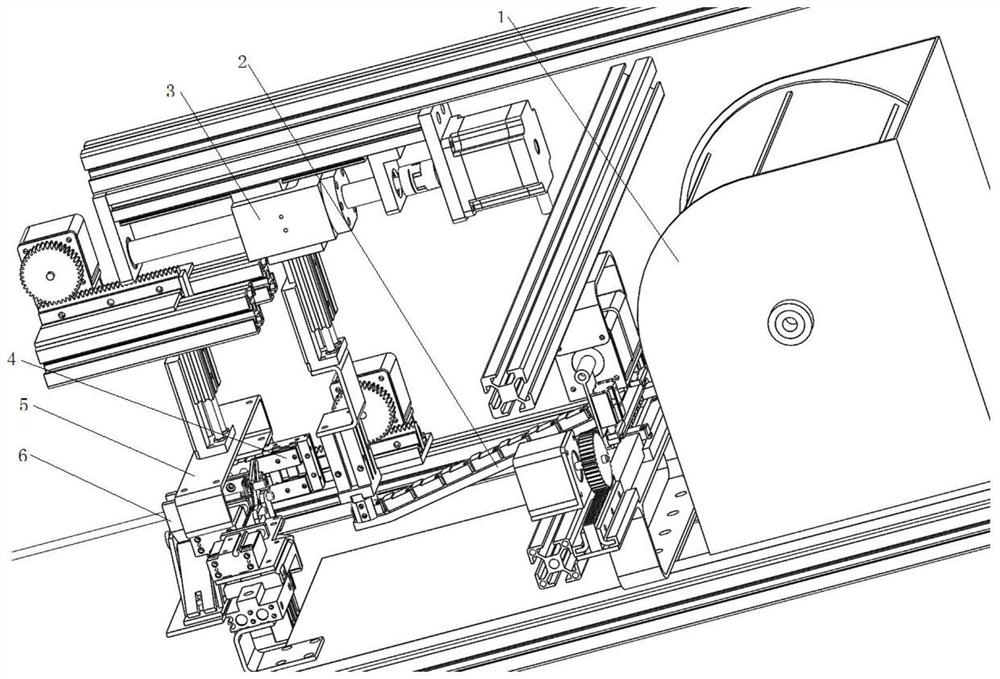

[0045] An automatic installation device for crystal heads of network cables, comprising a control system, a workbench, a rotating cage 1, a crystal head transmission mechanism 2, a crystal head installation mechanism 3, a core wire arrangement mechanism 5 and a clamp 6 installed on the workbench in sequence.

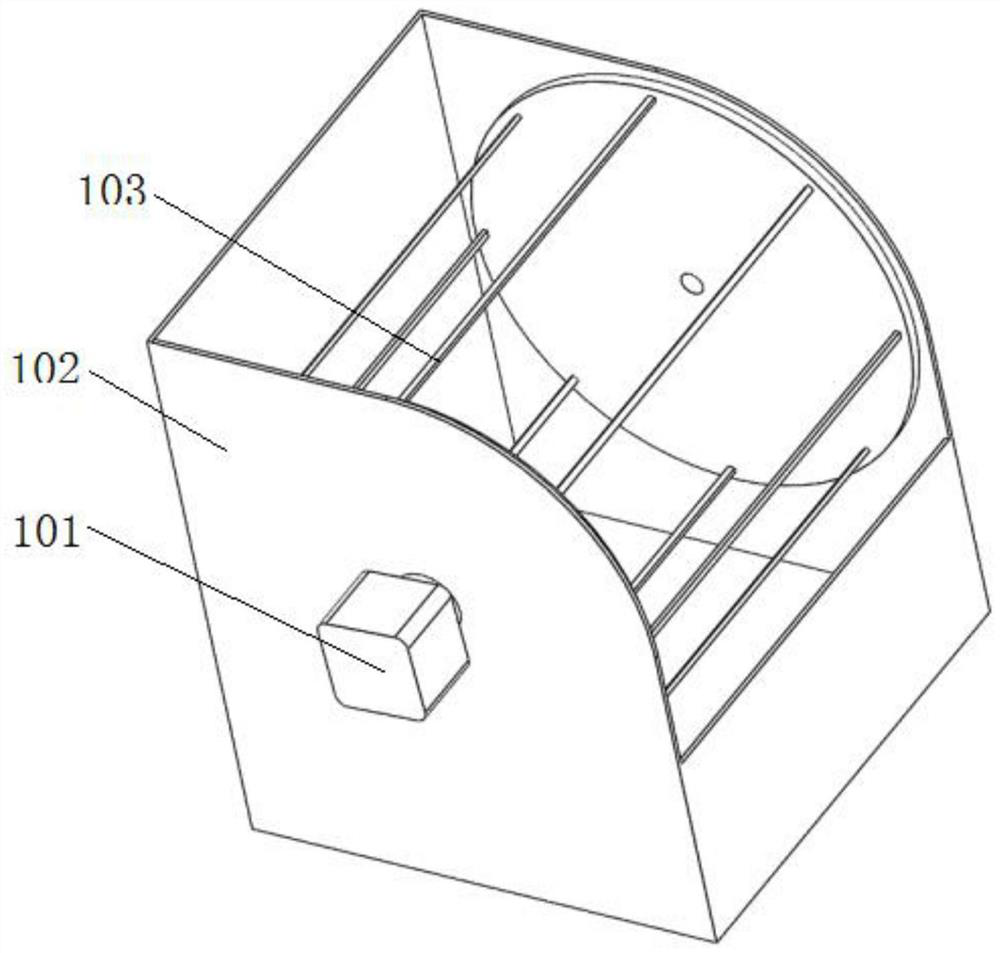

[0046] The rotating cage 1 includes a cage 102 and a rotating cage installed in the cage 102. The rotating cage is composed of two circular rotating plates and a hook rod 103 evenly installed between the two rotating plates. The rotating plate is installed on the cage 102. On the side wall, a first motor 101 is installed outside the side wall of the cage 102 .

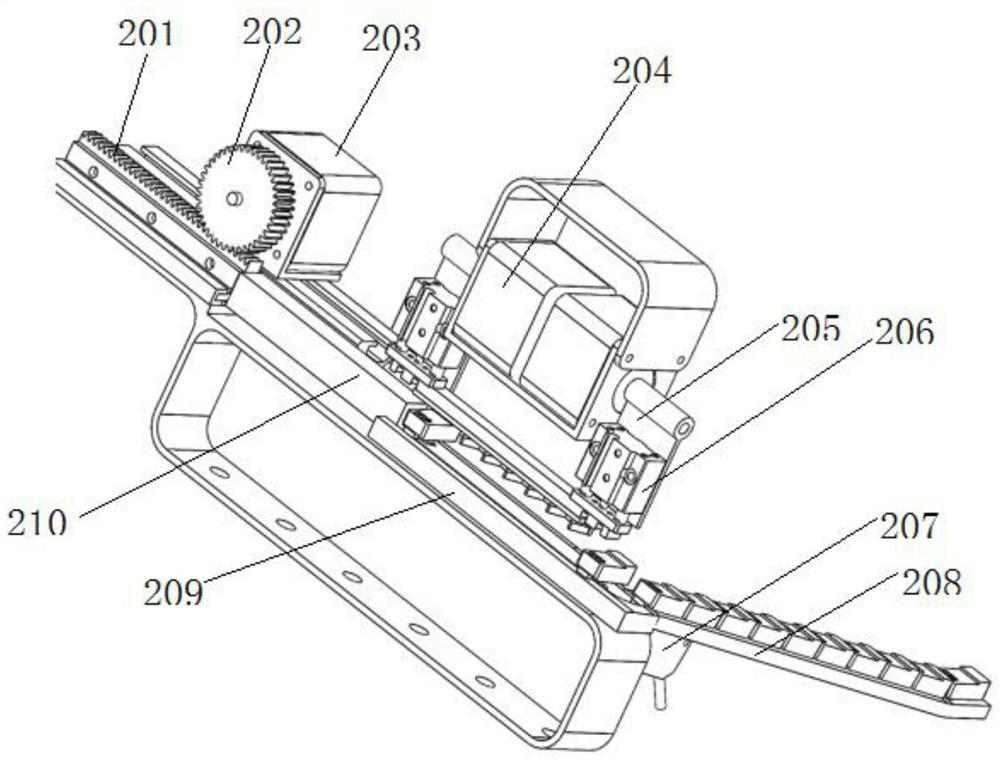

[0047] The crystal head transfer mechanism 2 includes a transfer station and a push station arranged side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com