Asynchronous motor structure

A technology for asynchronous motors and motor units, which is applied in the field of electric motors and can solve the problems of inconvenient replacement of a single iron core and other components, easy burning, and prone to sweeping accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

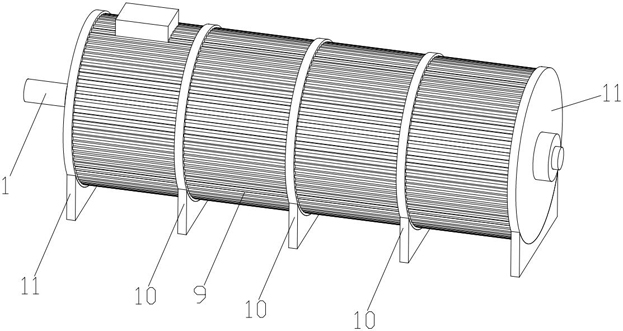

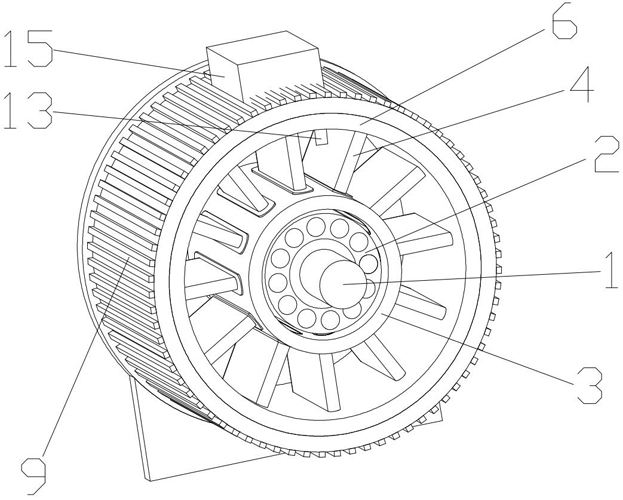

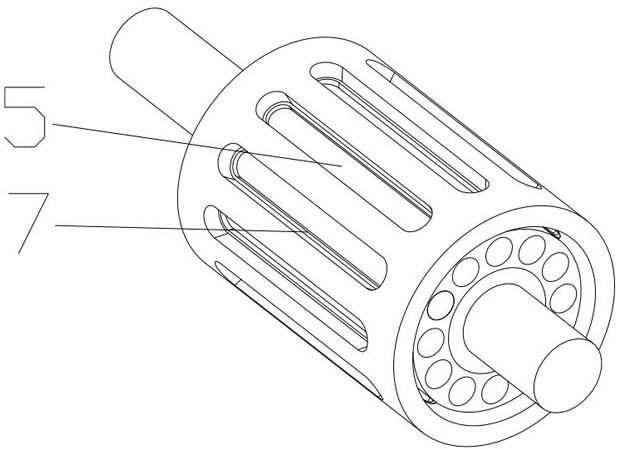

[0025] like Figure 1-5 As shown, an asynchronous motor structure includes a rotating shaft 1, on which several groups of motor units are arranged, and the motor unit includes a rotor 2 fixed on the rotating shaft 1, and an inner ring 3 is sleeved on the outer side of the rotor 2 , there is a gap between the inner ring 3 and the rotor 2; the inner ring 3 is provided with a slot 5 for inserting the silicon steel sheet 4, the outer side of the silicon steel sheet 4 is provided with an outer magnetic ring 6, the outer end of the silicon steel sheet 4 is connected The inner side walls of the magnetic ring 6 are in contact but not connected, and the silicon steel sheet 4 is wound with a coil.

[0026] Preferably, the bottom of the slot 5 is provided with a stop bar 7 , the bottom of the silicon steel sheet 4 is provided with a silicon steel sheet base 8 , and the silicon steel sheet base 8 is matched with the slot 5 . The silicon steel sheet is set in the form of insertion and pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com