Tobacco leaf stem and leaf separation equipment

A technology for separating stem leaves and tobacco leaves, which is applied in the field of tobacco leaf raw material processing equipment, can solve the problems of large equipment footprint, high labor costs, and different separation quality, so as to reduce equipment investment, reduce production costs, and achieve good separation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

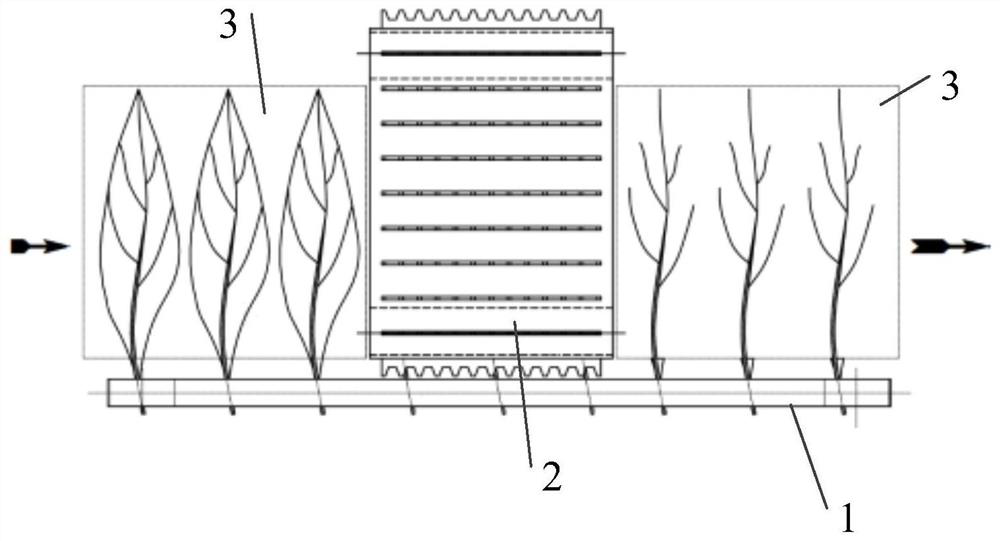

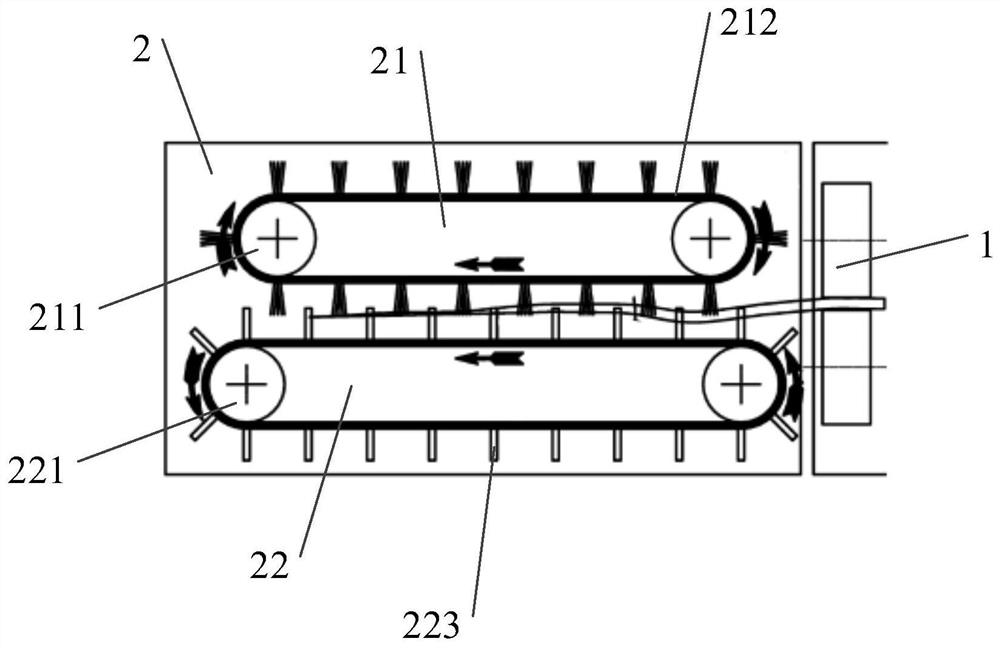

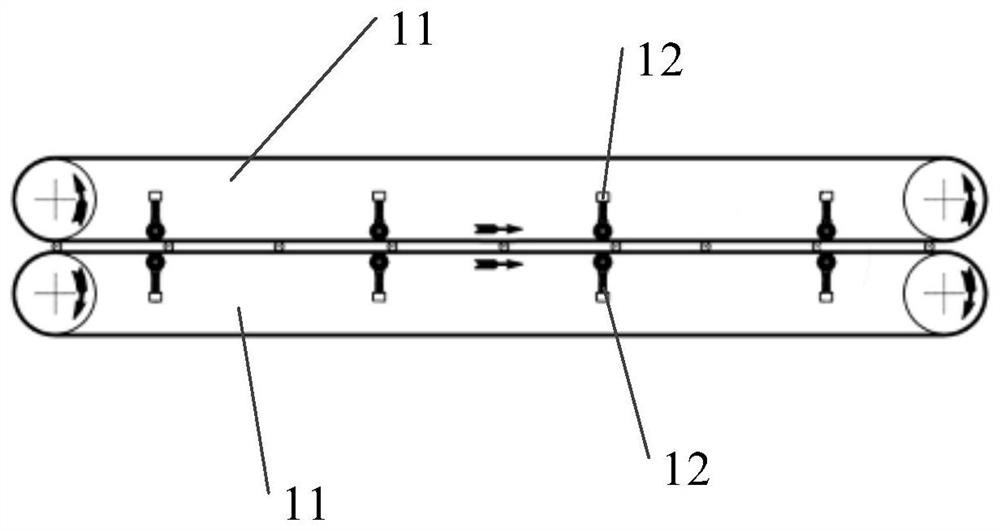

[0025] Such as Figure 1-2 As shown, the present invention provides a tobacco leaf stem separation device, comprising: a tobacco leaf clamping device 1, a stem leaf separation device 2 and an auxiliary platform 3, and the tobacco leaf clamping device 1 is located on one side of the auxiliary platform 3 for clamping The petiole of the tobacco leaves and transport the tobacco leaves; the stem leaf separation device 2 is located between the left and right auxiliary platforms 3. Specifically, as image 3 As shown, the tobacco leaf clamping device 1 includes two oppositely arranged conveying mechanisms 11, each conveying mechanism 11 is provided with a plurality of elastic pressing members 12, and the two elastic pressing members at opposite positions on the two conveying mechanisms 11 12 constitutes a compression mechanism, after the compression mechanism clamps the petiole, the tobacco leaves are transported to the stem-leaf separating device 2 by two conveying mechanisms 11, an...

Embodiment 2

[0030] Such as Figure 6 As shown, the present invention also discloses a tobacco leaf stem separation device, comprising: a tobacco leaf clamping device 1 and a stem leaf separation device 2, the tobacco leaf clamping device 1 is located above the stem leaf separation device 2, a tobacco leaf limit mechanism 21 and a tobacco leaf The tearing mechanism 22 is arranged left and right, so that the tobacco leaves are suspended and vertical to the ground to separate the stalks and leaves, without the need for an auxiliary platform 3. The layout is reasonable and the site investment is effectively reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com