Glass staple fiber training shoe production mold and production equipment using the mold

A technology of short glass fiber and production equipment, which is applied in the field of production equipment and short glass fiber training shoe production molds. It can solve the problems of low assembly efficiency and inability to ensure uniform quality, so as to improve assembly efficiency, change manual assembly methods, and ensure The effect of assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

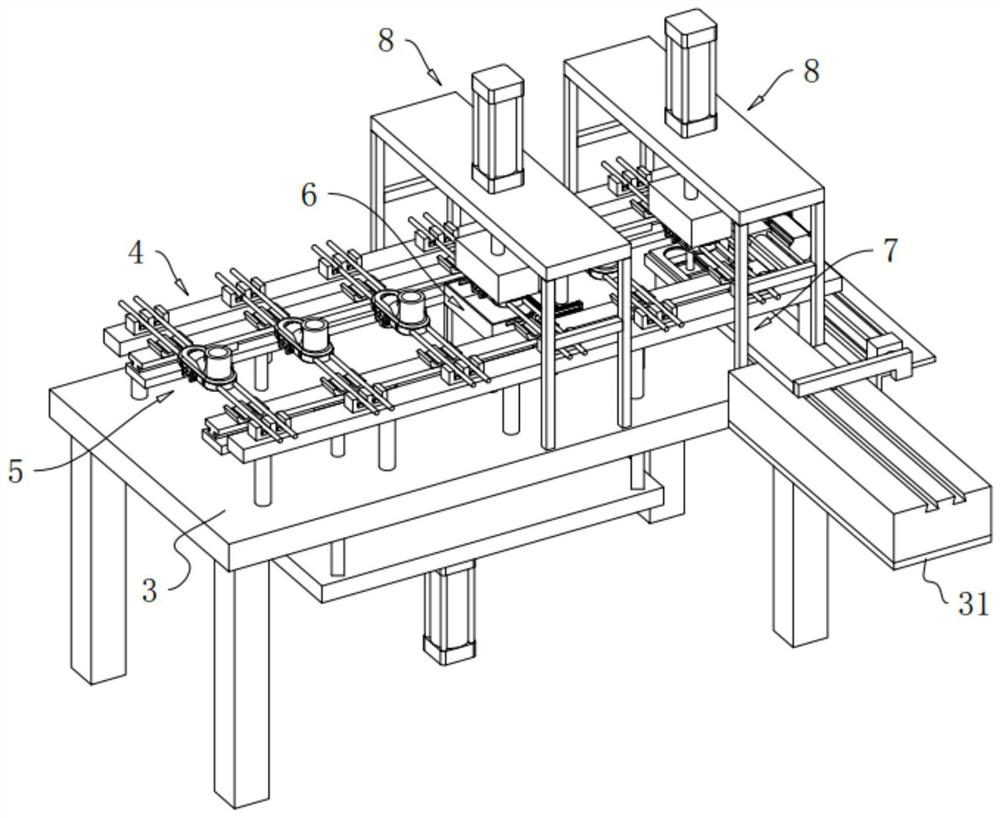

[0042] The following is attached Figure 1-10 The application is described in further detail.

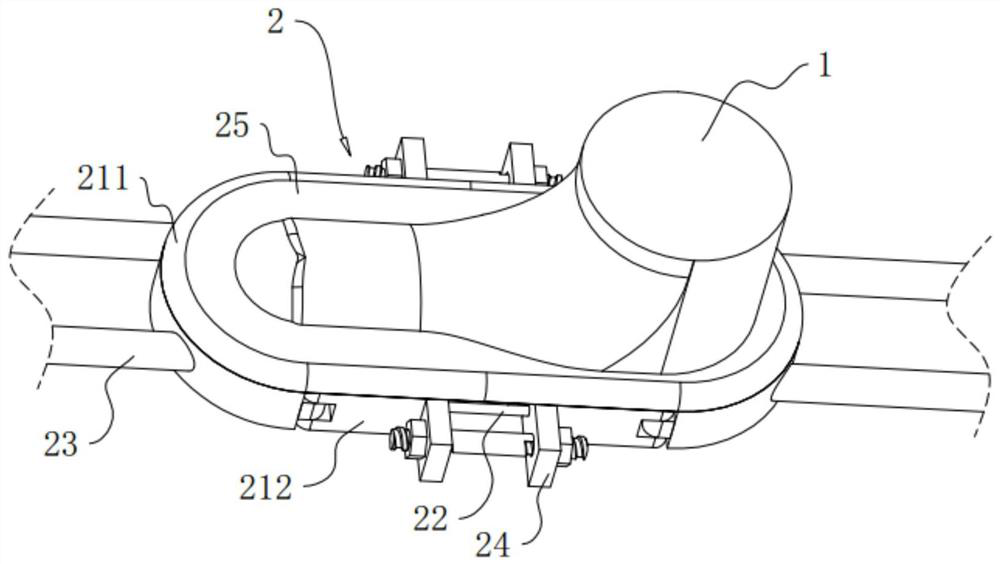

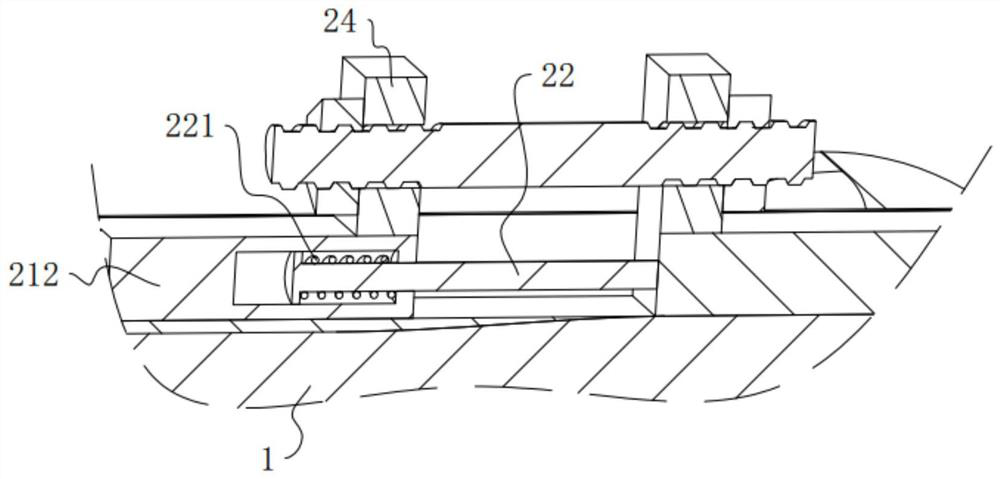

[0043] The embodiment of the present application discloses a production mold for short glass fiber training shoes, refer to figure 1 with figure 2 , including a mold body 2 for clamping the shoe 1, the mold body 2 includes a clamping portion, and the clamping portion includes an arc plate 211 for clamping the front end or rear end of the shoe 1, and the arc plate 211 Side plates 212 are hinged at both ends, and two sets of clamping parts are provided. The end faces of the side plates 212 in the two sets of clamping parts are oppositely arranged and connected to each other, and a connecting part is arranged between the side plates 212 in the two sets of clamping parts. , the connection part includes an insertion rod 22 fixedly connected to one of the side plates 212, the insertion rod 22 can be set as a T-shaped bar, and the insertion rod 22 is made of a deformable material to ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com