Steel ladle long nozzle installation system and method

An installation system and long nozzle technology, applied in metal processing equipment, manufacturing tools, casting melt containers, etc., can solve the problems of low installation efficiency, time-consuming and laborious, and achieve the effect of high work efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

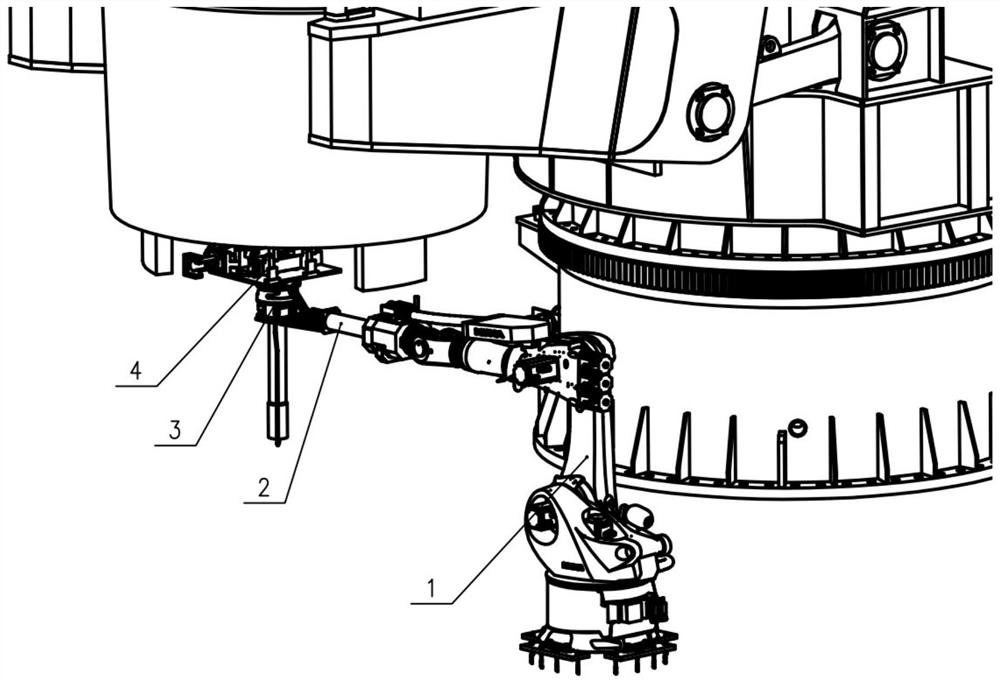

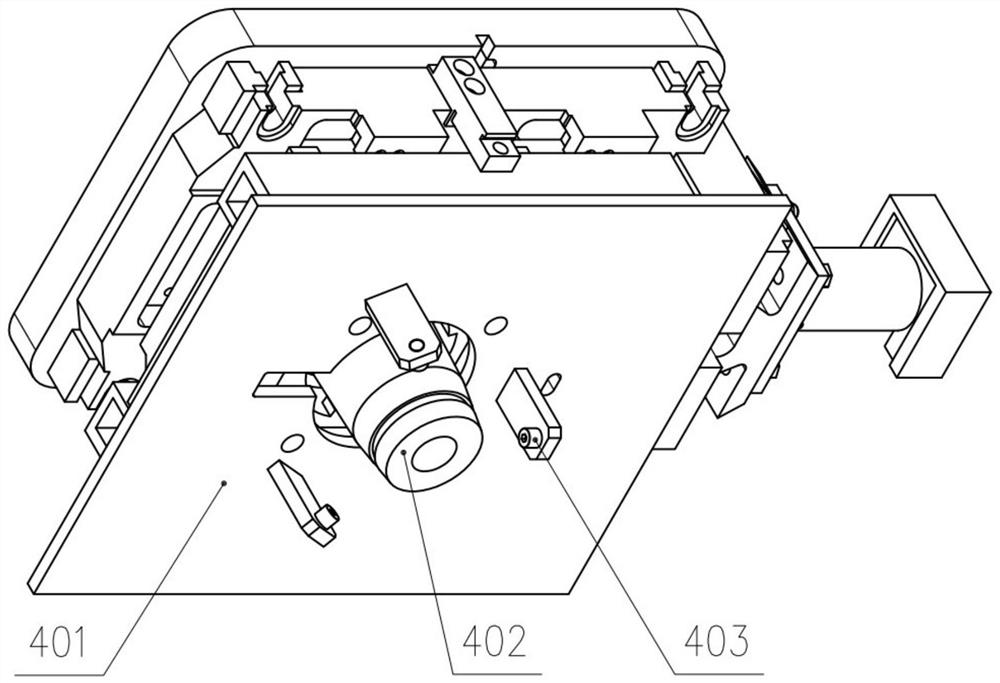

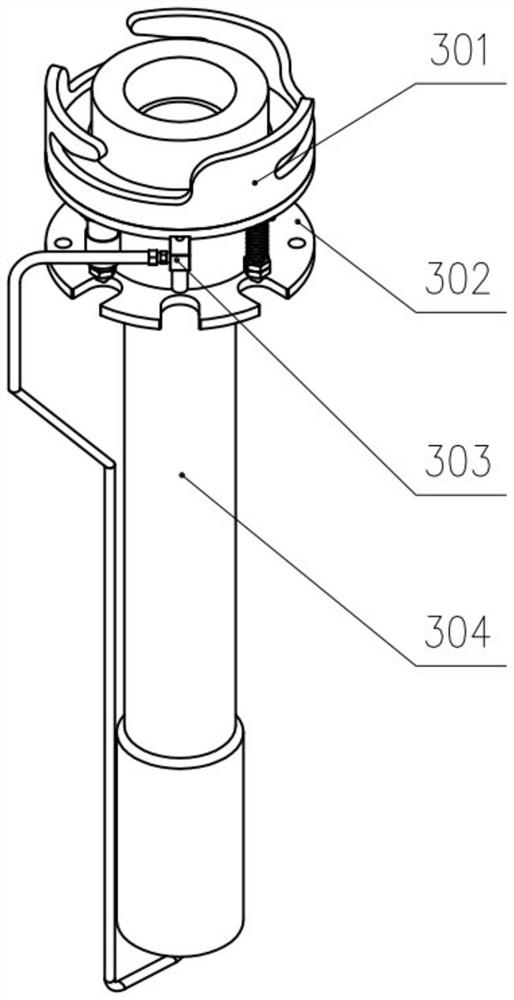

[0030] Such as Figure 1 to Figure 8 As shown, this embodiment provides a ladle shroud installation system, including a robot, a suspension tool 3 used to connect with the slide mechanism 4, and a lifting tool 2 driven by the robot 1, and the robot 1 is connected with a visual positioning device . The lifting tool 2 is used to support the shroud 304 and the hanging tool 3 to lift the shroud 304 and the hanging tool 3 to move as a whole. In addition, the visual positioning device in this solution includes a camera, which collects the position information of the slide mechanism 4 through the camera and sends it to the robot 1, and the robot 1 adjusts the relative positions of the suspension tool 3 and the slide mechanism 4 according to the position information collected by the camera, so as to realize the long nozzle 304 and the slide mechanism 4. Accurate docking installation of the slide mechanism 4. Since the action of the robot 1 according to the data collected by the came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com