Circulating powder scattering device

A powder-spraying device and circulating conveying technology, applied in printing, rotary printing presses, printing presses, etc., can solve the problems of affecting the thermal transfer effect of images, error-prone manual duty, and low degree of automation, achieving a high degree of automation and practicality. The effect of strong and market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

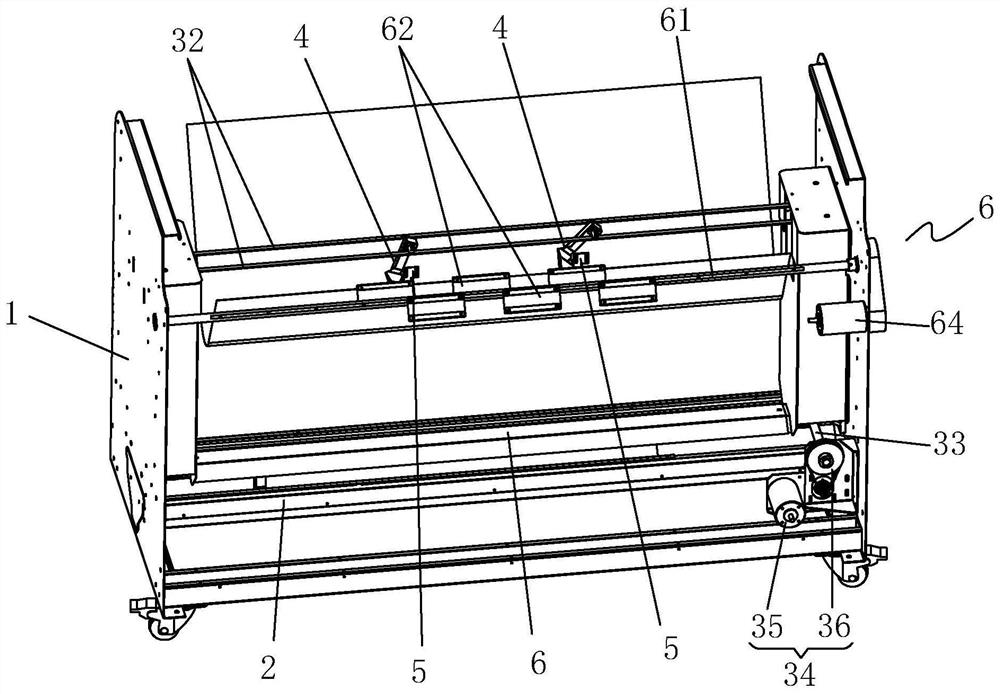

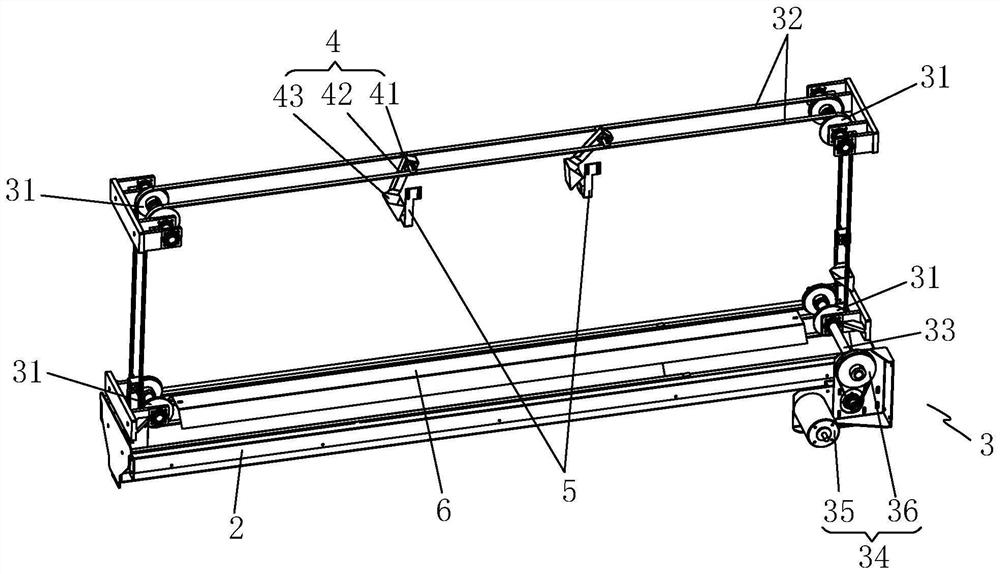

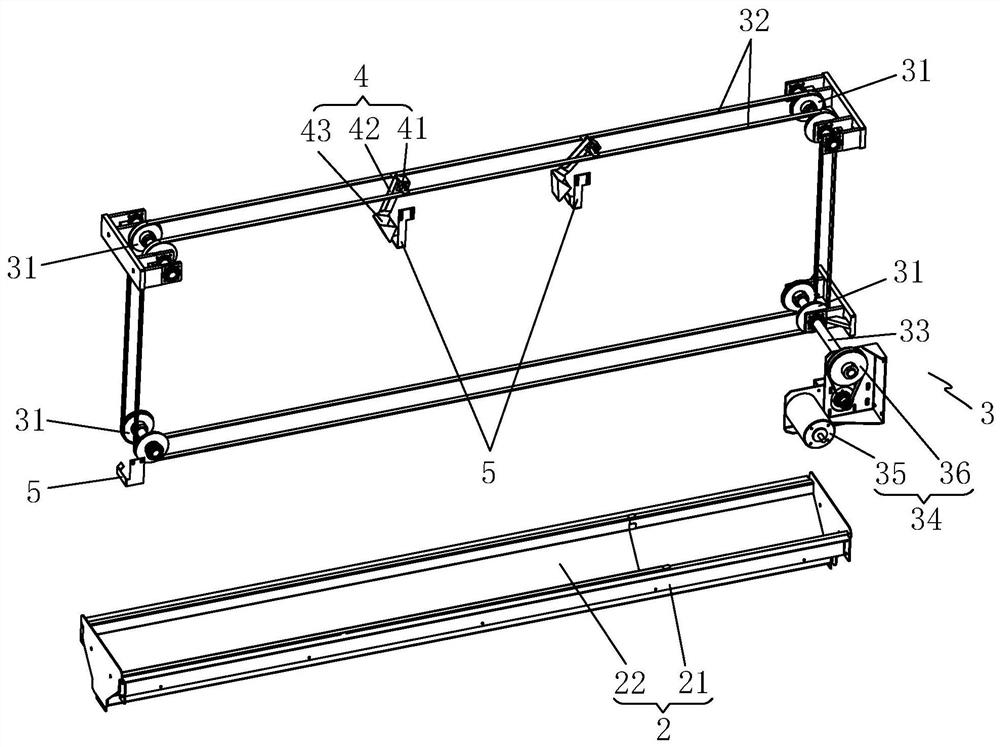

[0029] Such as Figure 1-3 As shown, a circulating powder spreading device includes a frame 1, which is provided with a powder loading mechanism 2 for loading and collecting excess hot-melt powder, a circulating conveying mechanism 3 through which thermal transfer substrates pass, At least one powder feeding mechanism 4 that moves with the circulation conveying mechanism 3 to transport the hot melt powder in the powder loading mechanism 2 to the thermal transfer substrate, and at least one is arranged above the thermal transfer substrate to tilt the powder feeding mechanism 4 A blocking mechanism 5 for sprinkling hot-melt powder on the thermal transfer substrate.

[0030] The circulation conveying mechanism 3 drives the powder feeding mechanism 4 to move. When the powder feeding mechanism 4 passes through the powder loading mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com