Processing equipment for jewelry handicrafts

A technology for processing equipment and handicrafts, applied to processing models, decorative arts, cleaning methods and utensils, etc., can solve the problems of poor fixing effect, time-consuming, and affecting the viewing effect of jewelry handicrafts for sale, so as to achieve convenient clamping and avoid direct contact , convenient and fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

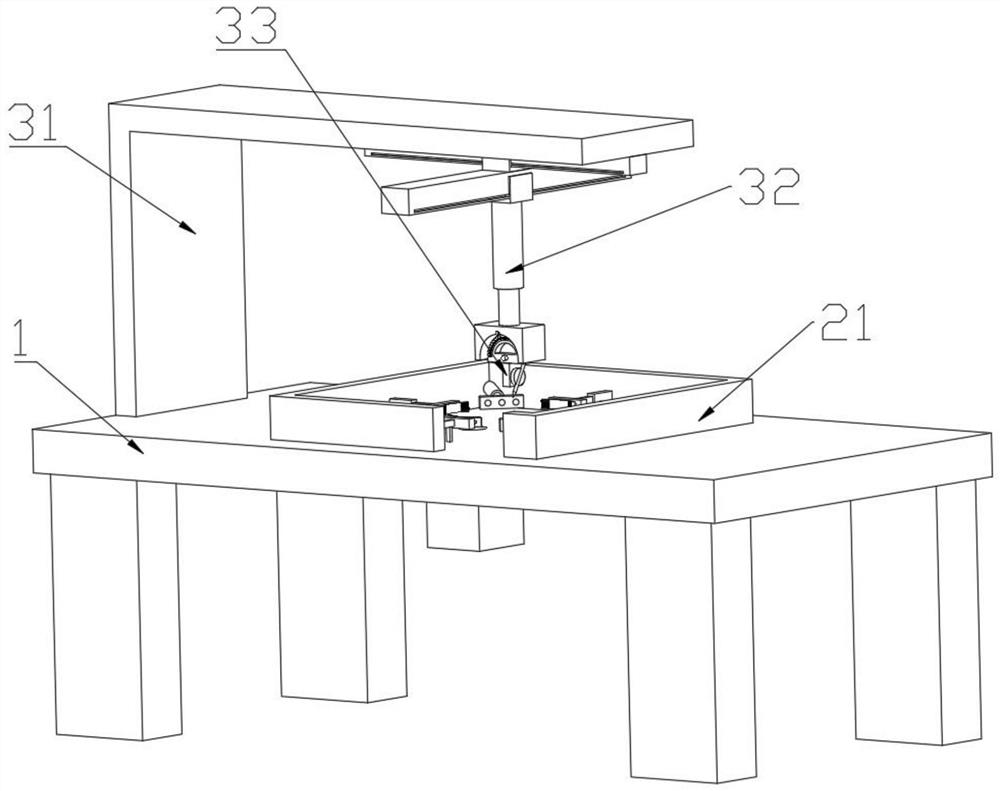

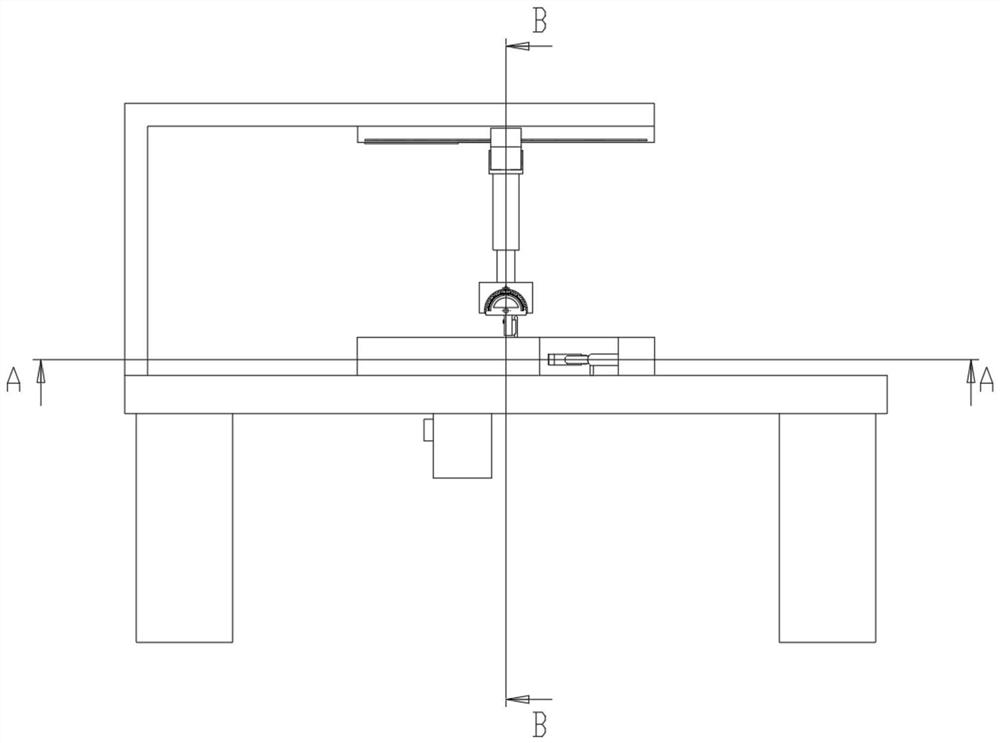

[0045] Such as Figure 1 to Figure 15 As shown, the processing equipment based on jewelry handicrafts provided by the embodiment of the present invention includes an operating table 1, a holding device for jewelry fixing and an engraving device for jewelry modification. 1, the fixed plate 21 on the fixed plate 21 is at least three sets of the first telescopic plate 22, the second telescopic plate 23 matched with the first telescopic plate 22, the first telescopic plate 23 for pushing the second telescopic plate 23 Cylinder 24, the clamping part arranged on the first telescopic plate 22 and the pre-fixed part used to improve the fixing effect, the multiple sets of the first telescopic plate 22 are centrally symmetrical;

[0046] Described clamping member comprises the clamping plate 251 that is located on the second telescopic plate 23, is located at the clamping piece 252 on the clamping plate 251, is connected with the clamping piece 252 fixed bar 253, is located at two sides...

Embodiment 2

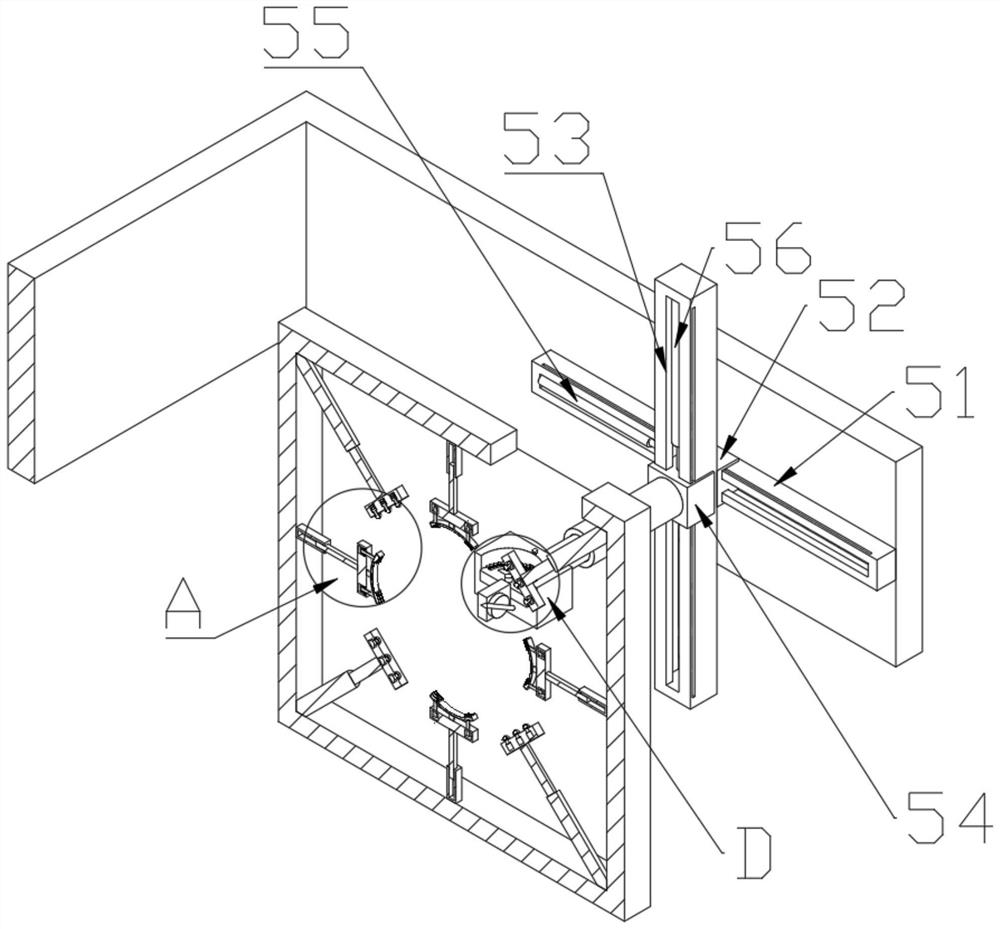

[0067] refer to image 3 , other structures remain unchanged, and the difference from Embodiment 1 is that an adjustment device for controlling the position of the drill bit 34 is provided between the bracket 31 and the second telescopic rod 32, and the adjustment device includes a first Slide rail 51, the first slide block 52 that is located on the first slide rail 51, the second slide rail 53 that links to each other with the first slide block 52, the second slide block 54 that is located on the second slide rail 53, is used for The second cylinder 55 that drives the first slider 52 to slide and the third cylinder 56 that is used to drive the second slider 54 to slide, the second telescopic rod 32 is fixedly connected with the second slider 54, and the first slide rail 51 and the second slide rail 53 are perpendicular to each other, so that the drill bit 34 can be accurately adjusted to a designated position, thereby improving applicability.

Embodiment 3

[0069] refer to Figure 13 , other structures remain unchanged, and the difference from Embodiment 1 is that the bottom of the end of the second telescopic plate 23 is fixedly connected with a baffle 61, and the baffle 61 is connected with the end of the first cylinder 24, and the baffle 61 The bottom of the bottom is provided with a spherical groove 62, and the inside of the spherical groove 62 is provided with a first ball 63 and a second ball 64, the diameter of the first ball 63 is larger than that of the second ball 64, and the diameter of the first ball 63 and the second ball 64, the second ball 64 is in contact with the inner wall of the spherical groove 62, and the console 1 is provided with a chute 65 matched with the first ball 63, by setting the baffle plate 61, the spherical groove 62, the first ball 63. The second ball 64 and the chute 65. The baffle plate 61 is located at the bottom of the second telescopic plate 23 and can support the second telescopic plate 23....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap