Wire harness pay-off device with automatic pay-off function

A technology of pay-off device and wire harness, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, etc. Line efficiency, uncoiling convenience, and the effect of reducing pay-off resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

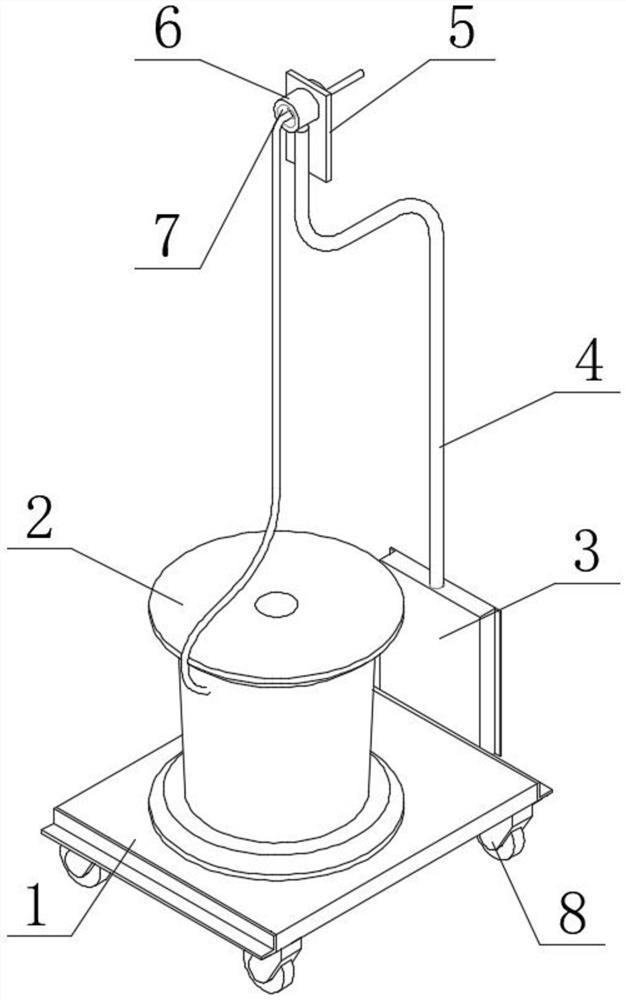

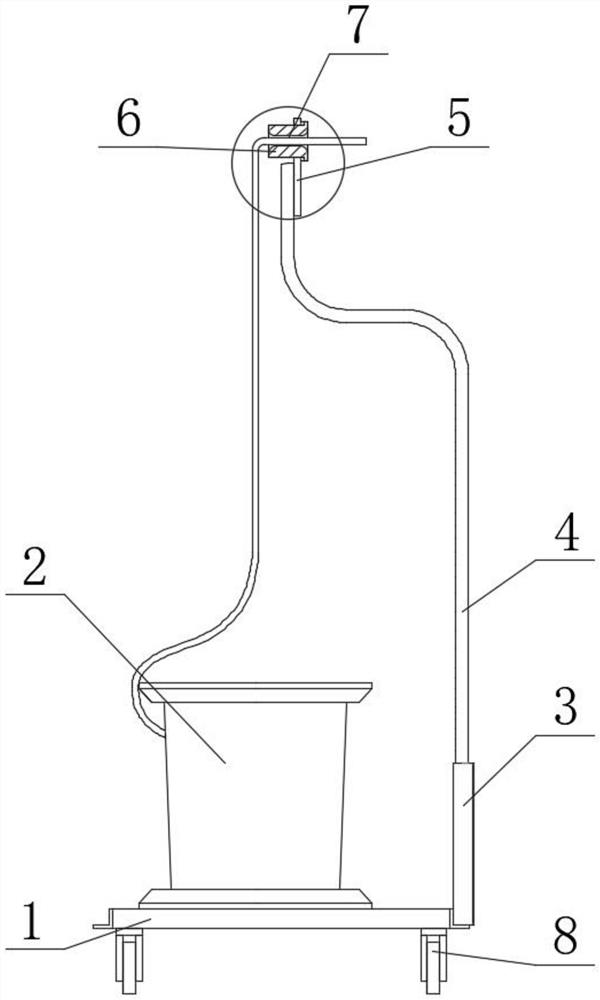

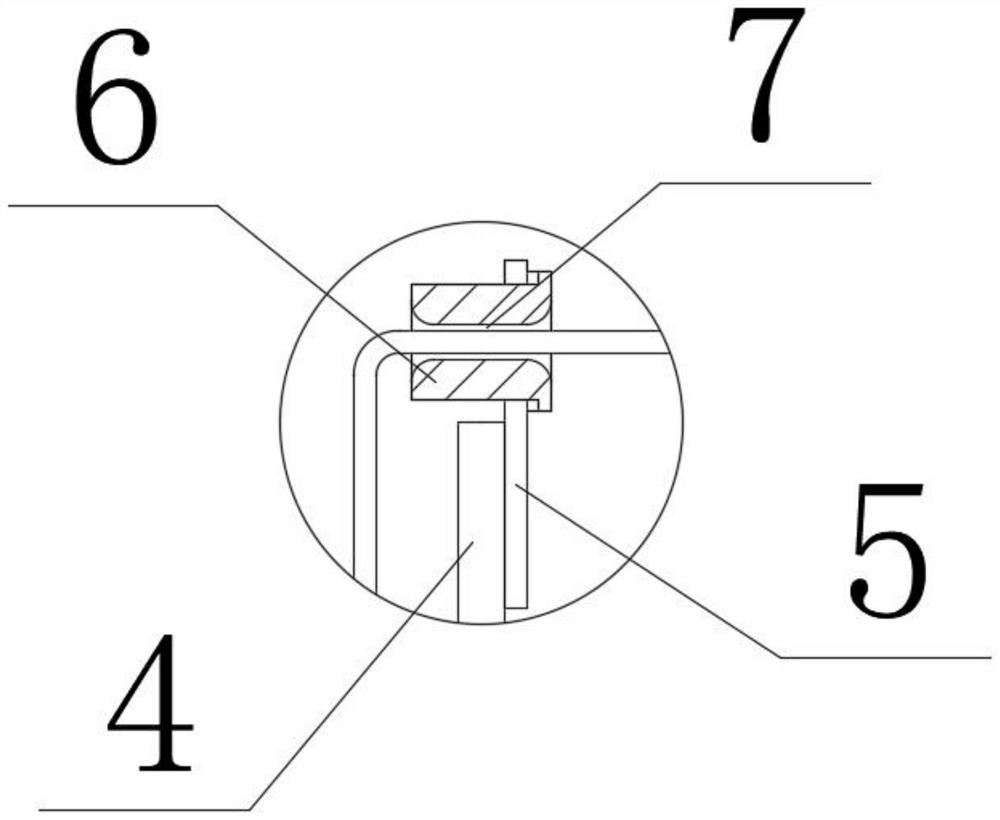

[0018] See Figure 1-3 The present invention provides a technical solution: automatic wire pay-off apparatus having a discharge line function, comprising a holder and an angle iron frame provided at one end of an angle iron frame 3, the top surface of an angle iron frame placed there payout reel 2, the holder 3 is detachably connected to the support bar 4 and some specific, the top of the support rod 4 is bent, and the tip portion near the vertical axis of the payout reel 2, the the bottom end of the support rod 4 through the holder 3, and the holder 3 are connected by bolts, to the top of the support bar 4 is detachably connected to the positive ceramic eye 6, specifically, the ceramic eyes located 6 payout reel 2 after the top, and the wire harness 6 into the eye ceramics, naturally drawn closer to the axial central portion of the payout reel 2, to avoid kinks, the discharge wire harness reel 2 is disposed through ceramic eye 6, the ceramic eye 6 Actinobacillus for payout reel 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com