Method and system for testing cleanliness of cleaned packaging container

A packaging container and testing method technology, applied in the direction of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the residue detection, the method and system for the cleanliness test of packaging containers that have not been retrieved, and the impact on packaging The healthy development of the container cleaning industry, etc., to achieve the effect of improving the accuracy and improving the flushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

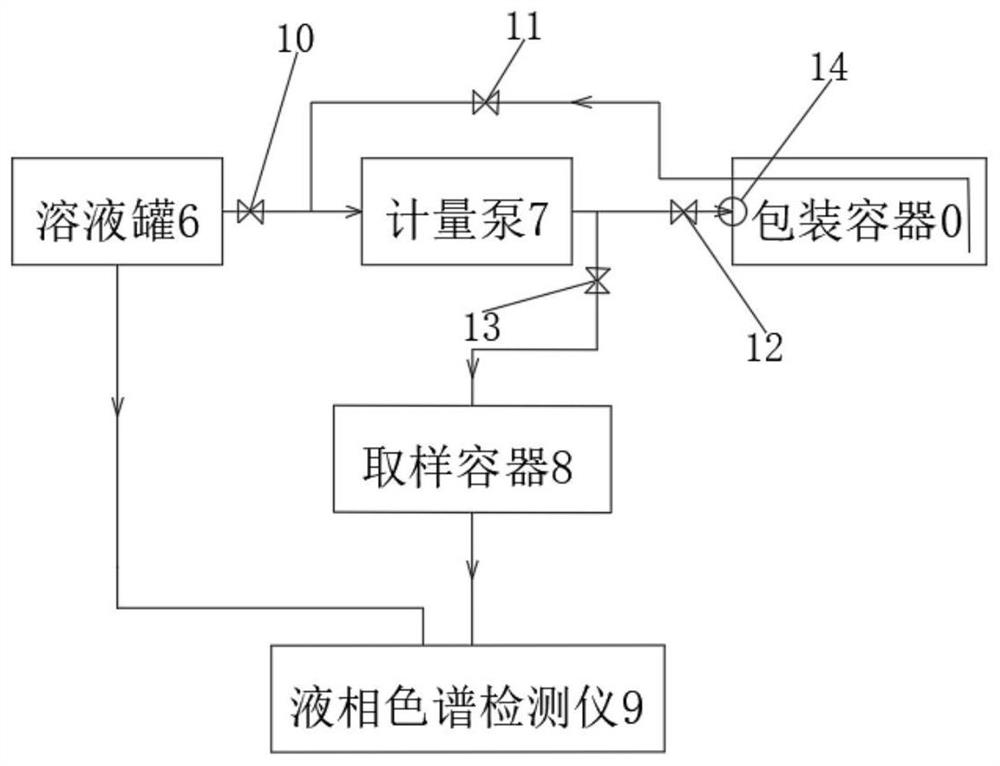

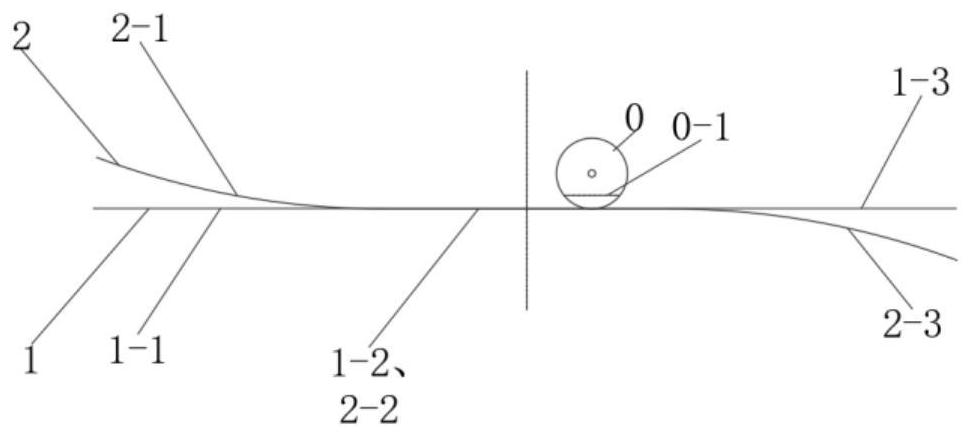

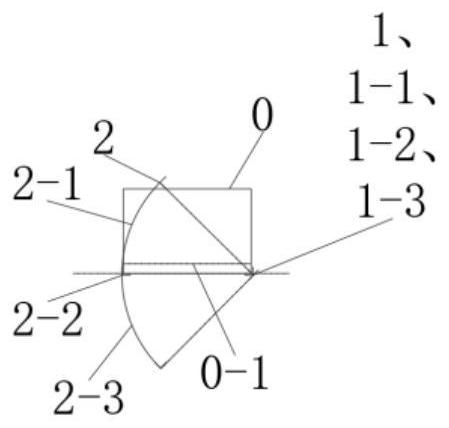

[0133] like figure 1 As shown, this embodiment provides a method for testing the cleanliness of a packaging container after cleaning. First, the concentration of the cleaning agent in the cleaning agent solution before washing is detected, and then the cleaning agent solution is injected into the cleaned packaging container O, so that the packaging The cleaning agent solution in the container 0 flushes the residue on the inner wall of the packaging container, the cleaning agent solution containing the residue in the packaging container 0 is discharged, and then the cleaning agent concentration of the cleaning agent solution containing the residue after washing is detected. , the ratio of the concentration of the cleaning agent before washing to the concentration of the cleaning agent after washing is the cleanliness of the packaging container 0 .

[0134]In this embodiment, the pre-washing cleaning agent concentration of the cleaning agent solution is detected first, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com