Shockproof heat dissipation structure, storage device and heat dissipation structure mounting method

A technology of heat dissipation structure and heat source, which is applied in the direction of record carrier structure parts, information storage, record information storage, etc. It can solve the problems that heat is not easy to dissipate or cool down, there can be no heat transfer structure, and heat dissipation is difficult to overcome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

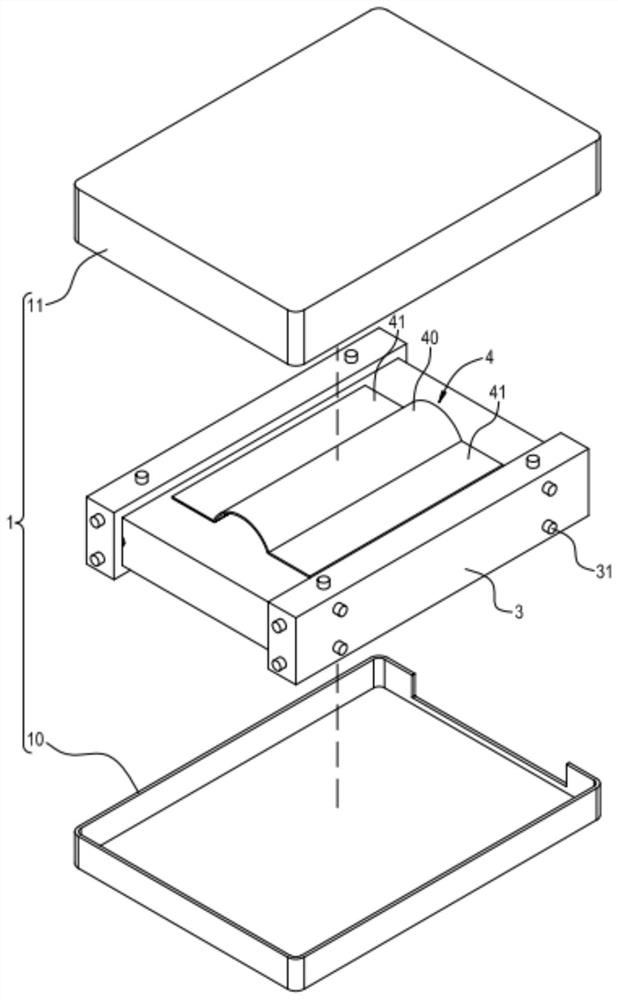

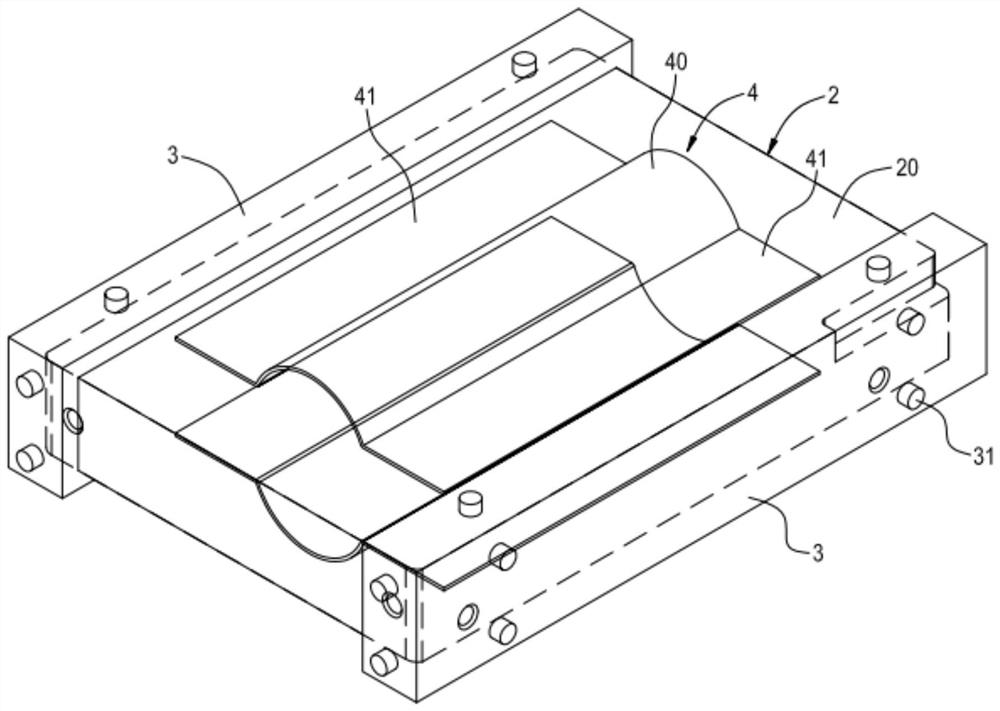

[0041] figure 1 It is a schematic diagram of the explosion of the heat conduction shell in the heat dissipation structure combined with shockproof provided by Embodiment 1 of the present invention; figure 2 It is a schematic diagram of the explosion of the hard disk, the shock-absorbing member and the heat transfer element in the anti-vibration heat dissipation structure provided by Embodiment 1 of the present invention; image 3 It is a schematic diagram of mutual cooperation of a hard disk, a shock-absorbing member, and a heat-transfer member in a heat dissipation structure combined with shock resistance provided by Embodiment 1 of the present invention.

[0042] Such as figure 1 , figure 2 and image 3 , the present embodiment provides a combined anti-vibration heat dissipation structure, which includes a heat-conducting shell 1 , a hard disk 2 , a shock-absorbing member 3 and a heat transfer element 4 .

[0043] Wherein, the heat-conducting shell 1 is mainly used to ...

Embodiment 2

[0051] Figure 7 A schematic cross-sectional view of a shock-proof heat dissipation structure provided in Embodiment 2 of the present invention, as shown in Figure 7 shown. Wherein, the flexible section 40 of the heat transfer element 4 can also be attached to the hard disk 2 or the heat source 20 , while the two fixed sections 41 are glued to the inner wall of the heat conduction shell 1 . With such a change in shape, the heat transfer element 4 can still be twisted and arranged in the spacing space 100 to realize heat conduction between the hard disk 2 or the heat source 20 and the heat conduction casing 1 .

[0052] This embodiment also provides a storage device, including the above-mentioned heat dissipation structure combined with shockproof, capable of realizing heat dissipation of the hard disk 2 or the heat source 20 . Among them, a hard disk 2 operates to generate a heat source 20 . The heat conduction element 4 that can be deformed by gravity is arranged between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com