Electric pump

An electric pump and component technology, applied in the field of electric pumps, can solve problems such as damage to the insulating paint layer, and achieve the effect of reducing extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0022] The electric pump in the following embodiments can provide flow power for the working medium of the automobile thermal management system. The working medium can be 50% ethylene glycol aqueous solution or clear water, and of course the working medium can also be other substances.

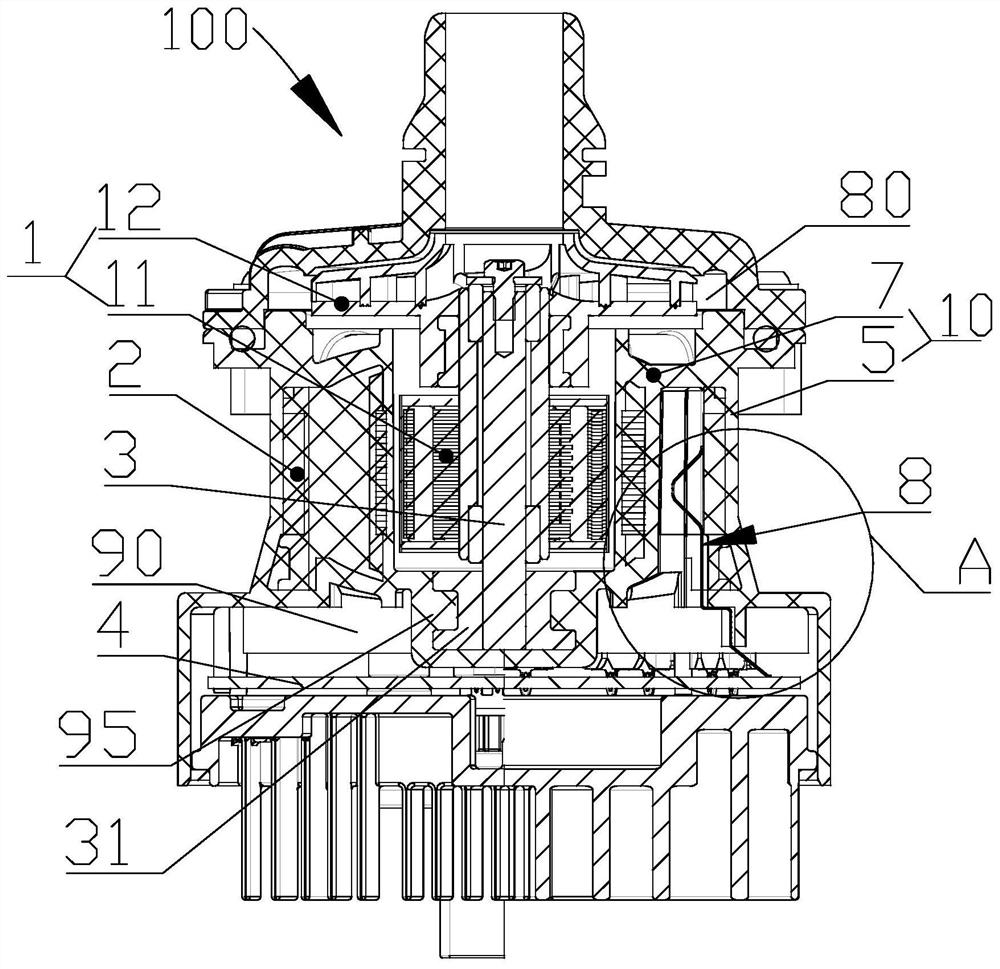

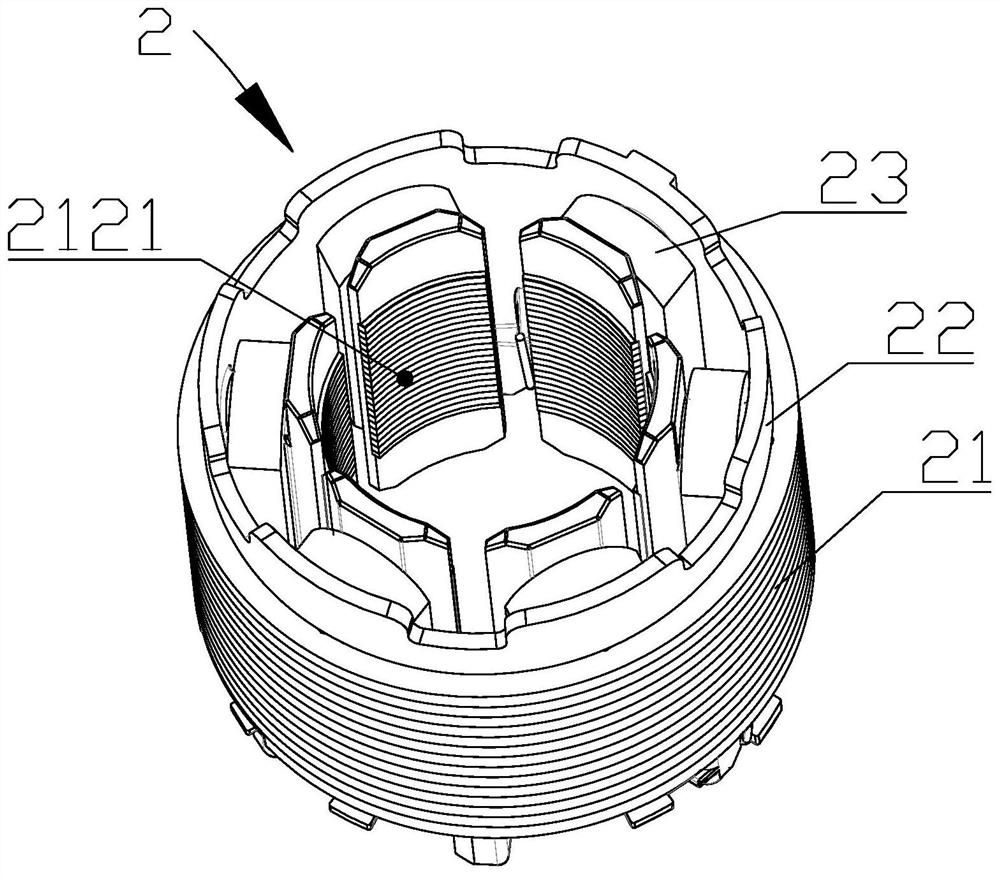

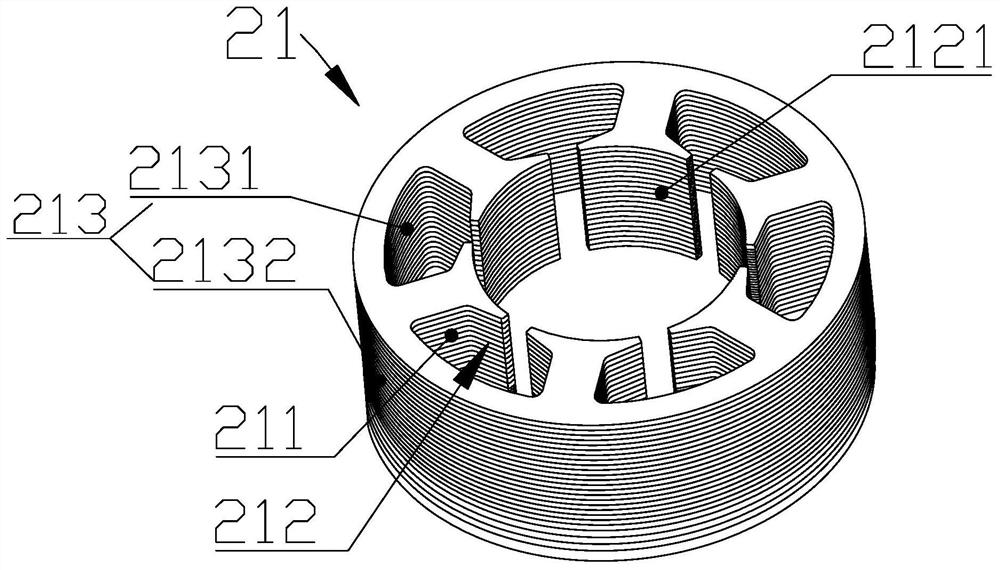

[0023] see figure 1 , the electric pump 100 includes a pump casing, a rotor assembly 1, a stator assembly 2, a pump shaft 3 and an electric control board assembly 4, the rotor assembly 1 is sleeved on the outer periphery of the pump shaft 3; the pump casing can form a pump inner cavity, and the electric pump 100 also includes an isolation part 7, the isolation part 7 divides the inner cavity of the pump into a first cavity 80 and a second cavity 90, the first cavity 80 can flow through the working medium, the second cavity 90 does not directly contact the working med...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap