Machining Technology of Shaft Seal Main Pump Impeller Cover in Nuclear Power Plant

A processing technology and impeller cover technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as low processing efficiency, impeller scratches, impeller cover deformation, etc., to solve clamping problems and prevent damage to workpieces , Guarantee the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A processing technology for the impeller cover of the shaft seal main pump of a nuclear power plant, using a vertical machine tool with non-standard tools for lathe sequence, using a five-axis machining center with an angle head, combined with a three-sided blade tool, and performing numerical control programming. The above method includes the following steps:

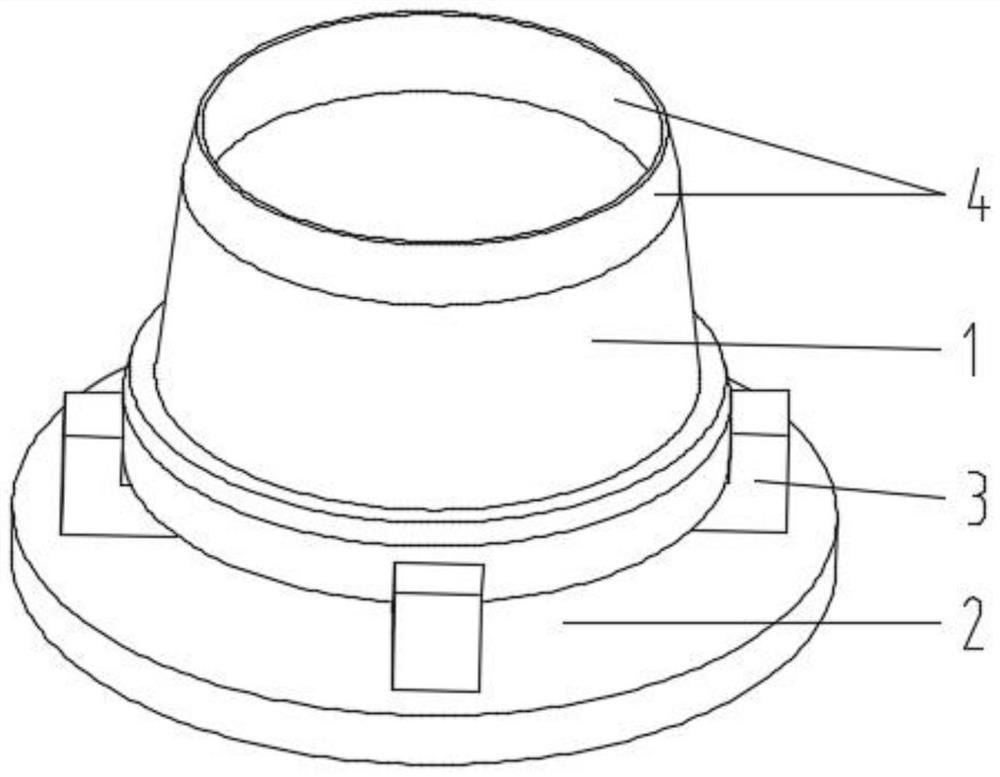

[0018] 1) After placing the impeller cover blank 1 on the lathe workbench 2 for alignment, fix the impeller cover blank 1 with the worktable claws 3, and turn the upper position 4 of the inner and outer circles of the impeller cover blank 1, as shown in figure 1 shown;

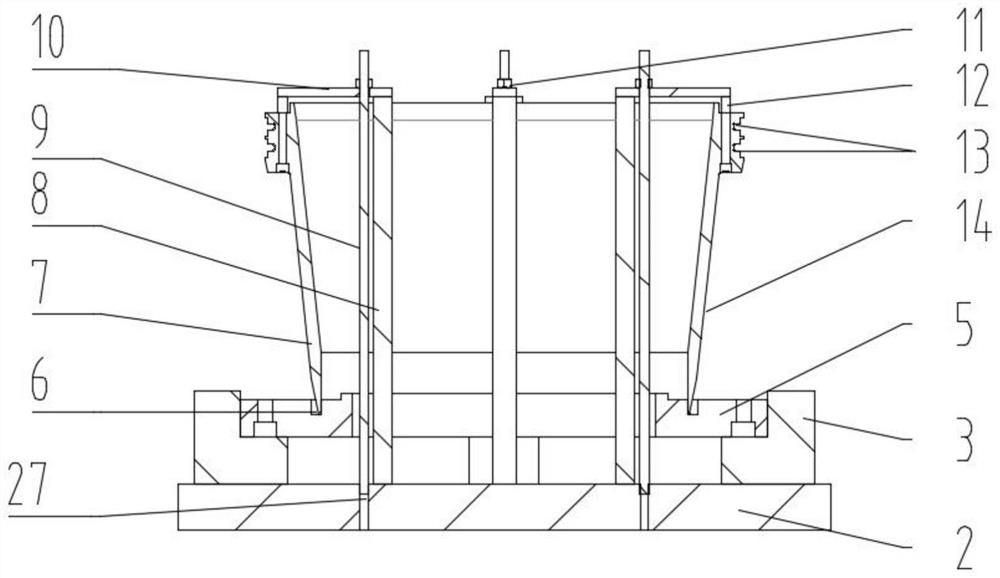

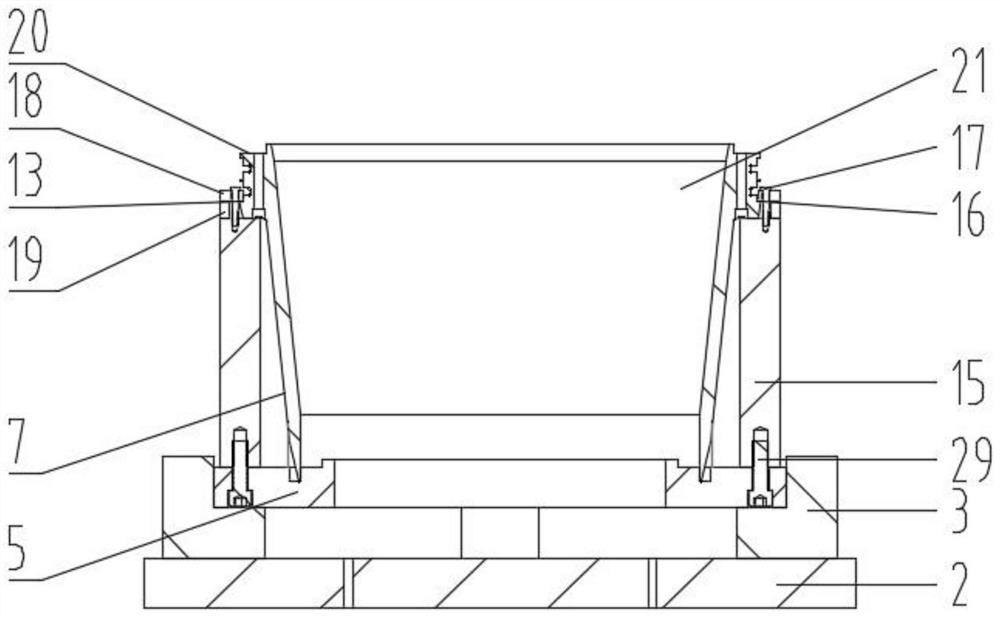

[0019] 2) Place the tire 5 on the lathe workbench 2 for alignment, fix the tire 5 with the claws 3 of the workbench, turn the impeller cover 7 into the seam 6 of the tire 5, and put the threaded pull rod 9 at both ends Put it into the threaded hole 27 of the lathe workbench 2, pass the first pressure plate 10 through the tie rod 9, place the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com