Sanding equipment based on horizontal machine tool

A machine tool and sanding technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of increased work intensity, large space, and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

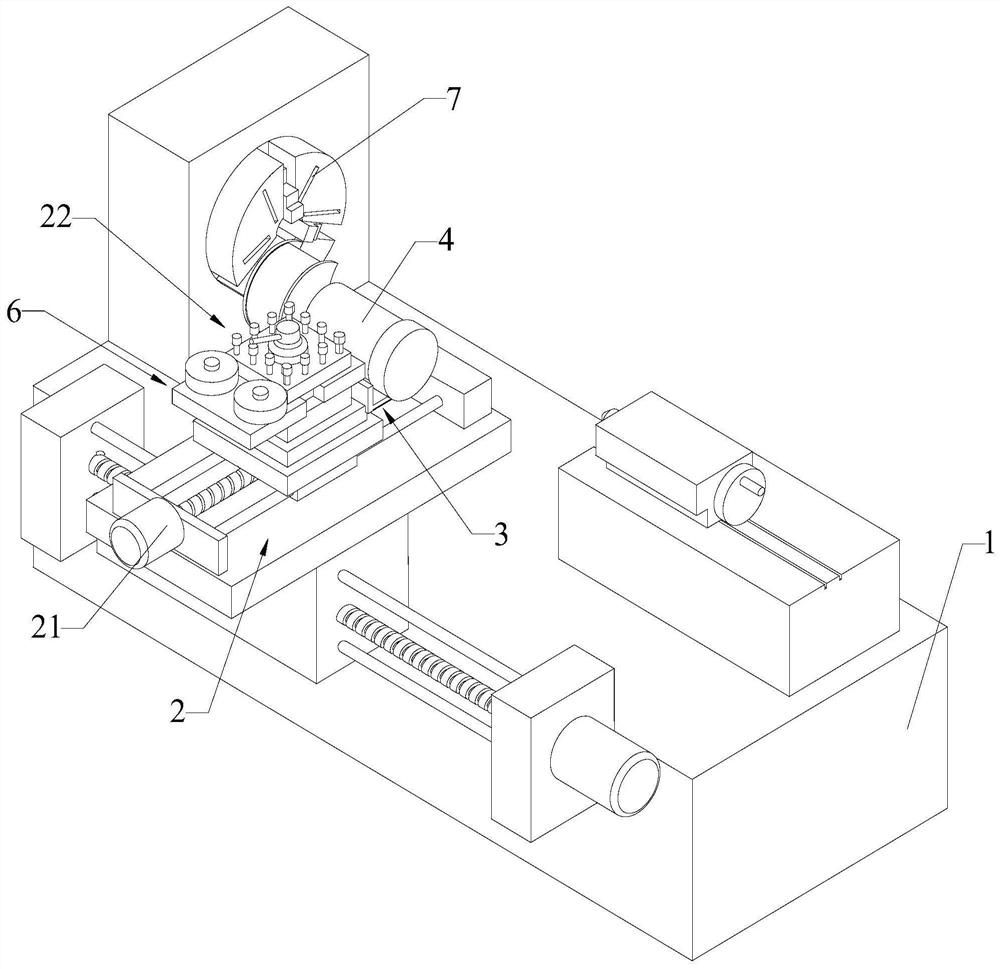

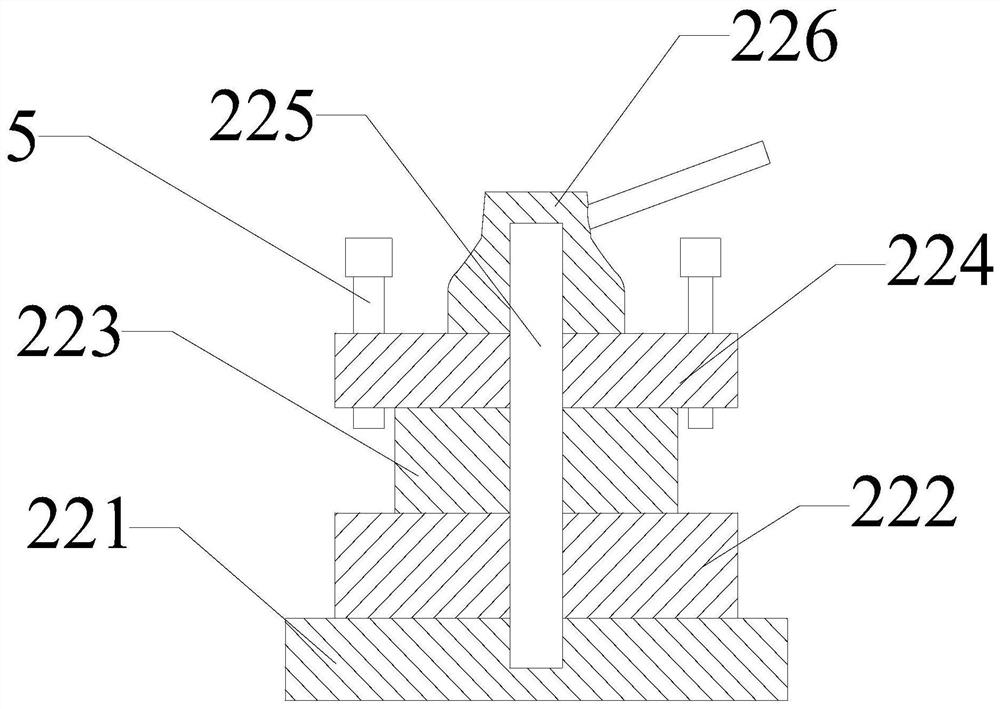

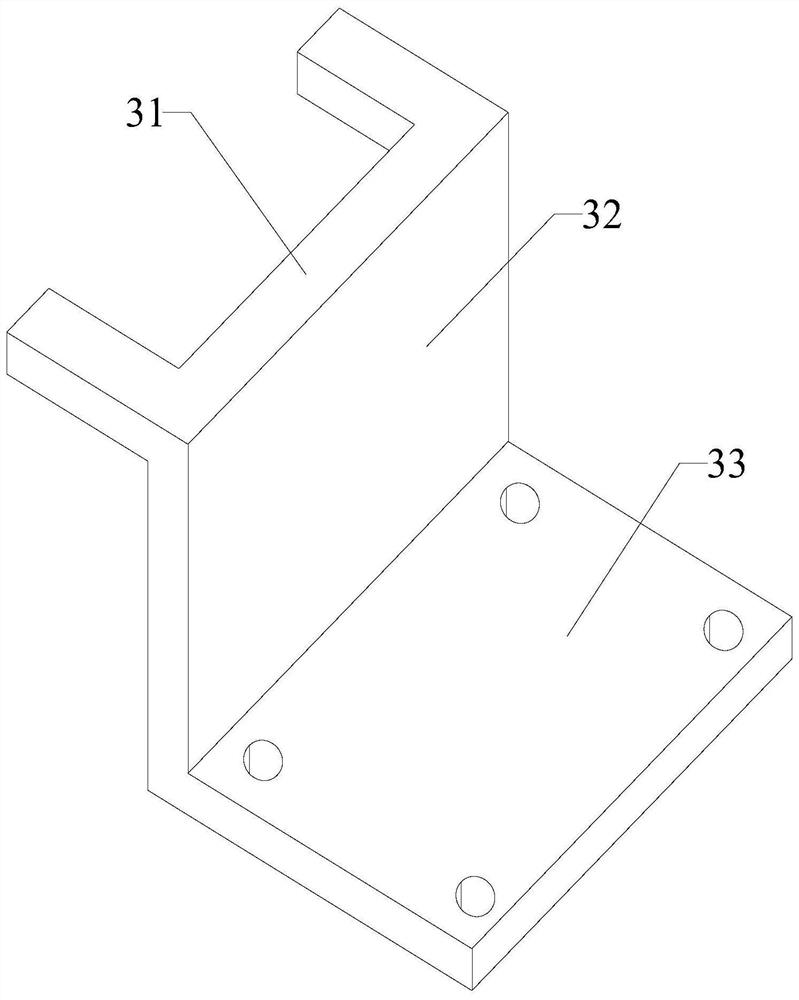

[0060] Please refer to Figure 1 to Figure 3 As shown, a sanding equipment based on a horizontal machine tool includes a lathe body 1, a support hanger 2, a mounting frame 3 and a sander 4; the support hanger 2 is arranged on the slide box of the lathe body 1, The support hanger 2 includes a linear slide 21 and a clamp 22, and the travel direction of the slide 21 of the linear slide 21 is perpendicular to the travel direction of the slide box of the lathe body 1; the clamp 22 includes a base 221 and a rotating seat 222 , a support block 223, a clamping plate 224, a threaded rod 225 and a threaded handle 226; the base 221 is arranged on the slide table of the linear slide table 21; the rotating seat 222 is placed on the top surface of the base 221; the The support block 223 is fixedly connected on the upper surface of the rotating seat 222; the lower surface of the clamping plate 224 is fixedly connected with the support block 223, and the clamping plate 224 is provided with a ...

Embodiment 2

[0062] Please refer to figure 1 and Figure 4 As shown, the sanding equipment based on the horizontal machine tool also includes a balance device 6, the balance device 6 includes a load plate 61 and a weight block 62, one side of the load plate 61 can be inserted between the rotating seat 222 and the clamping plate 224 between, and tighten the fastening bolts 5 to fix on the support hanger 2; the weight block 62 can be placed on the load plate 61. The grinding wheel of the sander 4 is provided with a grinding wheel guard. The chuck of the lathe body 1 is provided with reserved installation grooves 7 at radial intervals. The lower end surface of the fastening bolt 5 is provided with a rubber pad.

[0063] To sum up, the present invention provides a sanding equipment based on a horizontal machine tool. A support hanger is added to the horizontal machine tool, and the installation frame is inserted between the rotating seat and the clamping plate, and then the fastening bolt i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com