Anti-swing shock isolation device

An anti-sway and shock-isolation technology, which is applied in the direction of shockproof, building components, building structures, etc., can solve the problems of large swing, overturning, and torsional vibration of the protected structure, so as to enhance the effect of shock isolation and avoid torsional vibration or overturning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

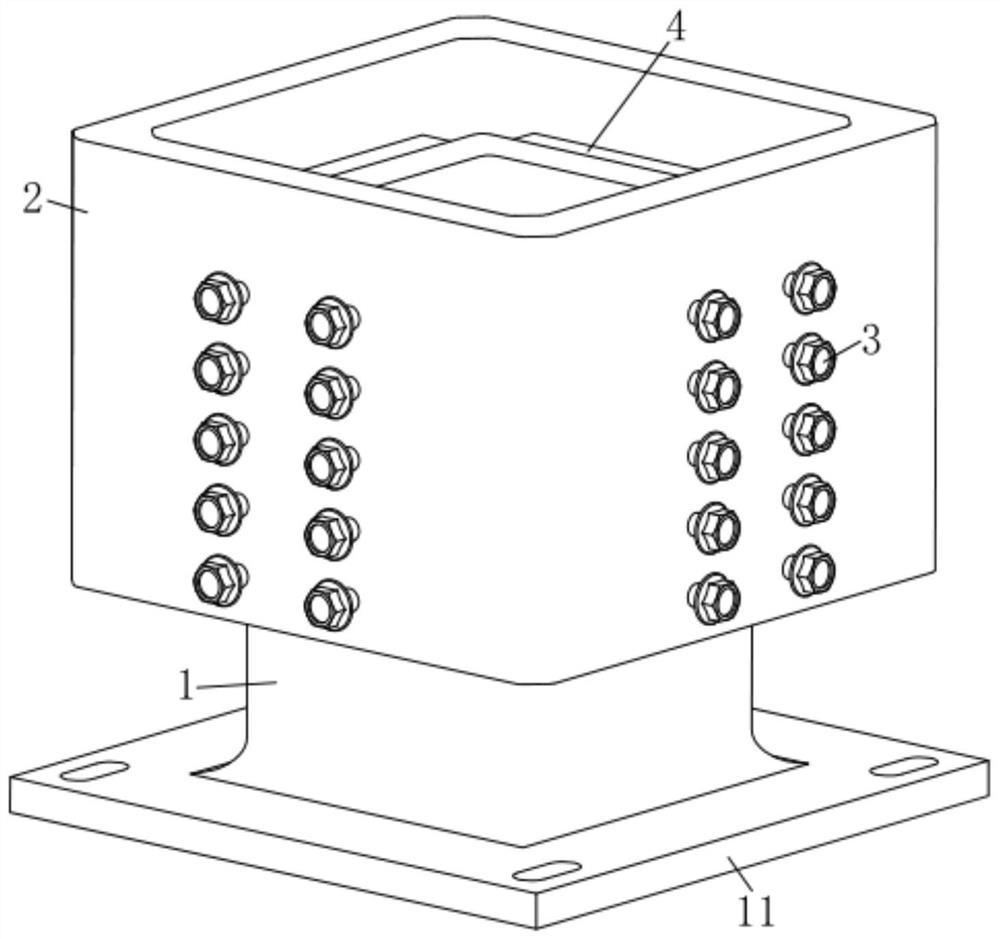

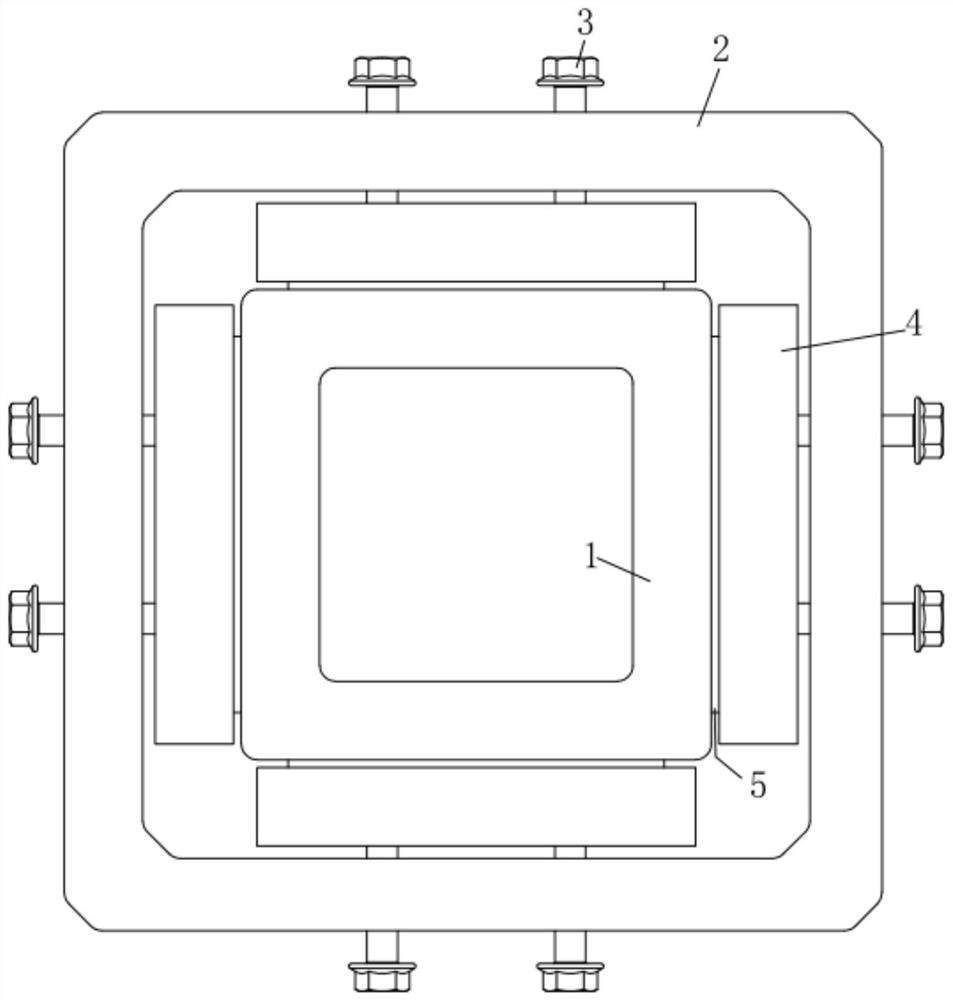

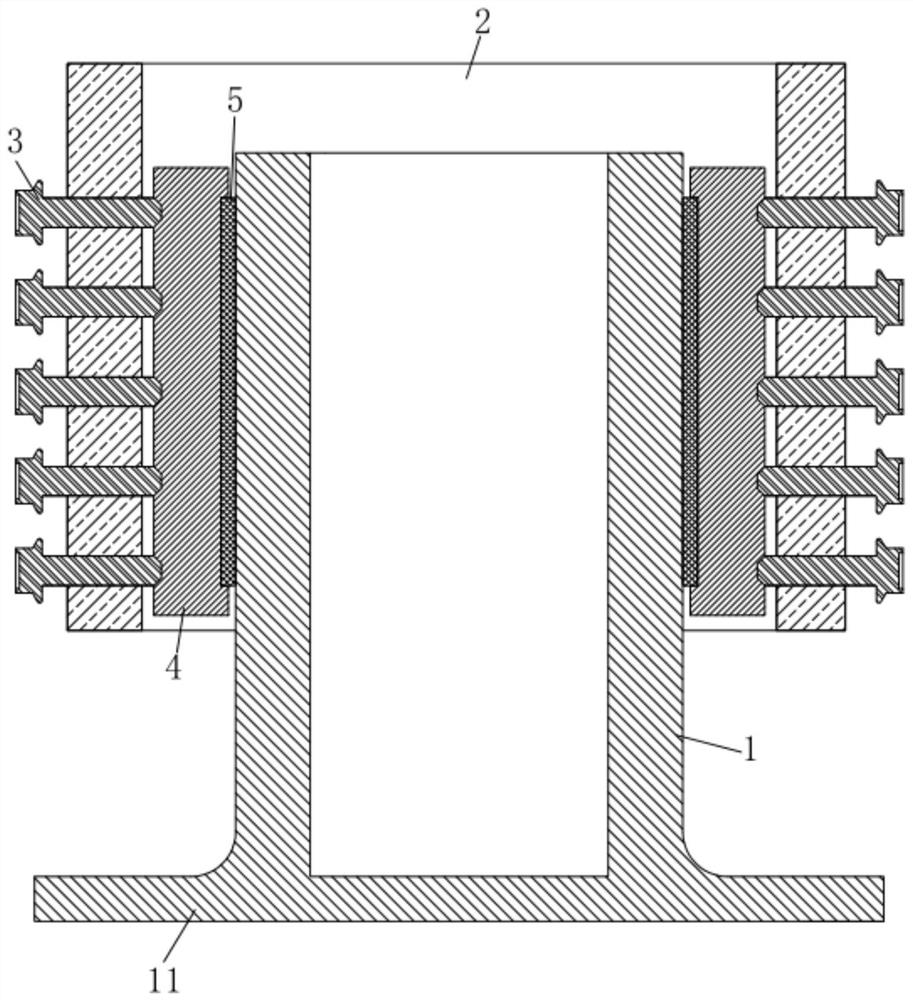

[0059] An anti-sway vibration isolation device includes an inner cylinder 1, a hollow outer cylinder 2, a movement mechanism, prestressed bolts 3, and a fixed plate 11, such as figure 1 shown. Both the inner cylinder 1 and the outer cylinder 2 are arranged in a cylindrical structure and are arranged in a vertical direction. The fixed plate 11 is arranged in a plate-shaped structure. The lower end surface of the inner cylinder 1 is welded to the fixed plate 11. The structure is fixed and connected by bolts. The outer cylinder 2 is sleeved outside the inner cylinder 1. When vibration occurs or not, the upper surface of the outer cylinder 2 is higher than the upper surface of the inner cylinder 1, and the lower surface of the outer cylinder 2 is higher than the inner cylinder. The lower surface of the cylinder 1. The movement mechanism is arranged between the inner cylinder 1 and the outer cylinder 2, and the prestressed bolt 3 horizontally passes through the side plate of the o...

Embodiment 2

[0069] When the movement mechanism is the laminated rubber bearing 6, bolts can also be threaded from the inner side of the inner cylinder 1 to the outer surface, so that the bolts are threaded with the connecting plate on the side of the laminated rubber bearing 6 close to the inner cylinder 1, so that The laminated rubber bearing 6 will not slide relative to the inner tube 1 .

[0070] Each side plate of the inner cylinder 1 is provided with a through hole, and each through hole has a bolt installed from the inner surface of the inner cylinder 1 to the outside, until the bolt and the laminated rubber support 6 face the connecting plate on the side of the inner cylinder 1 threaded connection.

Embodiment 3

[0072] Protected when the pressure provided by the protected structure against sway vibration isolation devices is greater than the maximum lateral support force of the laminated rubber bearing 6, or greater than the friction between the laminated rubber bearing 6 and the outer side of the inner cylinder 1 Vertical vibration isolation components are installed under the structure.

[0073] The structure and number of vertical shock-isolation components are not limited, and can provide vertical restoring force, so that the protected structure can return to the normal use state after the vibration occurs and the vibration is over. In this embodiment, the vertical shock-isolation assembly includes an upper connection structure, a steel spring, and a lower connection structure that are sequentially fixedly connected as an example, such as Figure 7 shown. Both the upper connection structure and the lower connection structure are made of rigid materials and are arranged in a plate-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com