Side support connecting structure for vibration reduction of towering equipment

A technology of connecting structures and side supports, which is applied in the direction of mechanical equipment, supporting machines, building components, etc., can solve the problems of limiting thermal expansion of towering equipment, large additional bending moment, etc., and achieve the effect of avoiding torsional vibration and reducing local stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

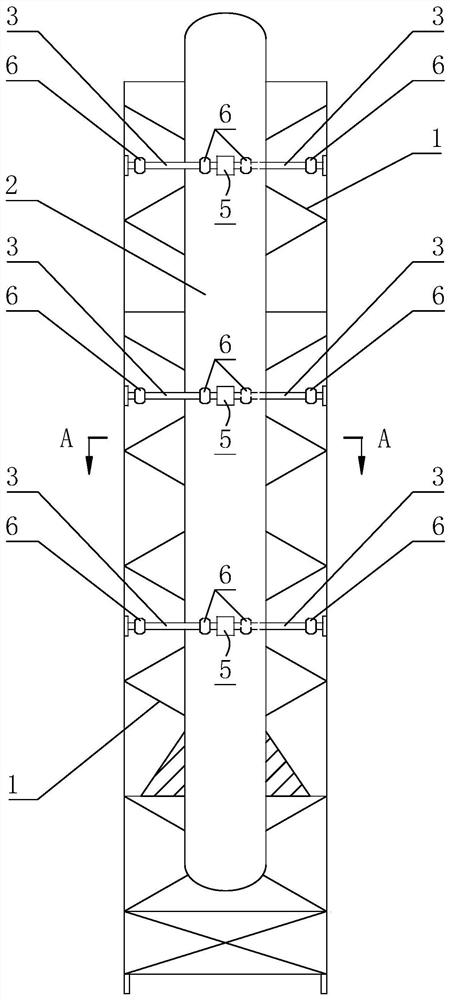

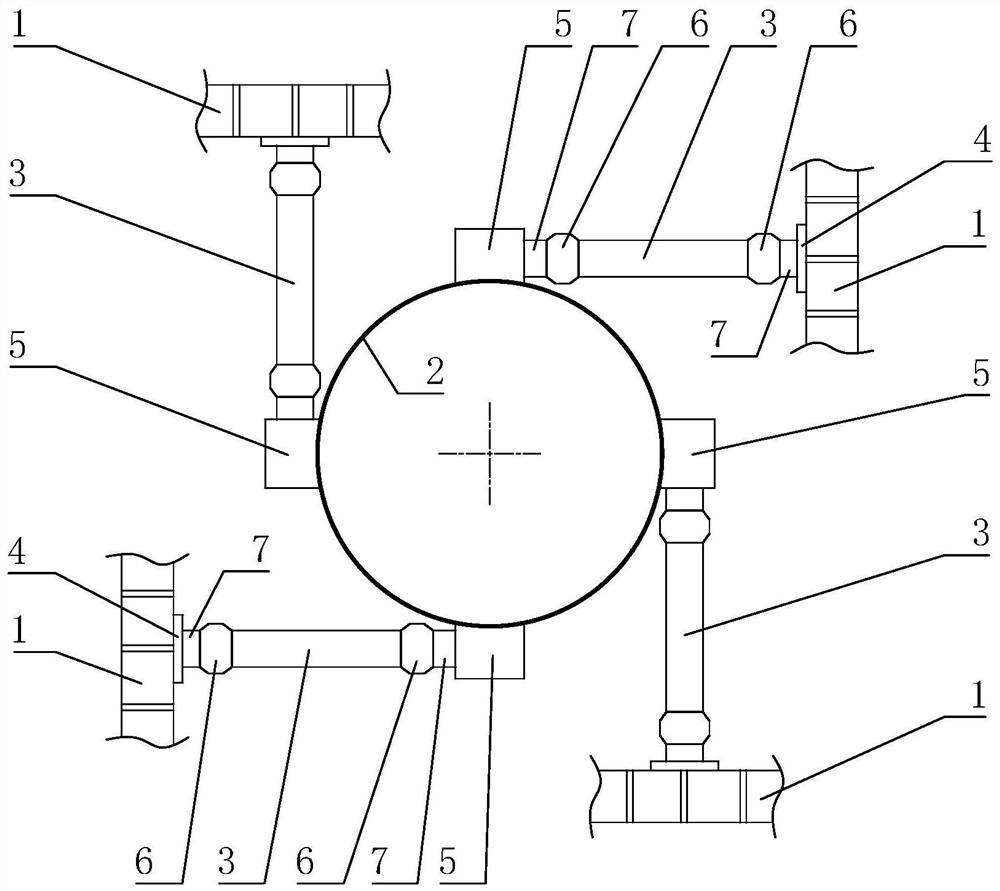

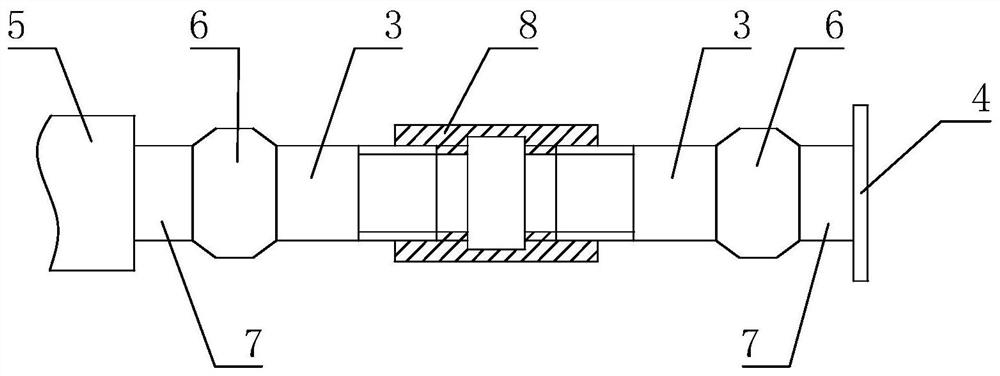

[0017] see figure 1 and figure 2 , a side support connection structure for high-rise equipment vibration damping (abbreviated as side support connection structure) of the present invention includes a connecting rod 3, and the connecting rod 3 is arranged along the tangential direction of the high-rise equipment 2 cylinder. Both ends of each connecting rod 3 are respectively connected (welded) with a universal joint 6, wherein one universal joint 6 is connected with the equipment end support 5 through a connecting piece 7, and the other universal joint 6 The connecting piece 7 is connected to the support 4 at the frame end, and the universal joint 6 is flexibly connected to the connecting piece 7 . The connecting piece 7 can be a steel pipe or rod, etc.; it can be provided with the universal joint 6, or it can be added by the user. The equipment end support 5 is fixed on the cylindrical body of the towering equipment 2 , the frame end support 4 is fixed on the frame 1 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com