Permanent magnet stepless speed reducer

A continuously variable speed reducer technology, applied in the direction of electromechanical devices, control mechanical energy, electromechanical transmission devices, etc., can solve the problems of smooth leakage and oil leakage of the output shaft of the reducer, avoid shaft torsional vibration, high transmission efficiency, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

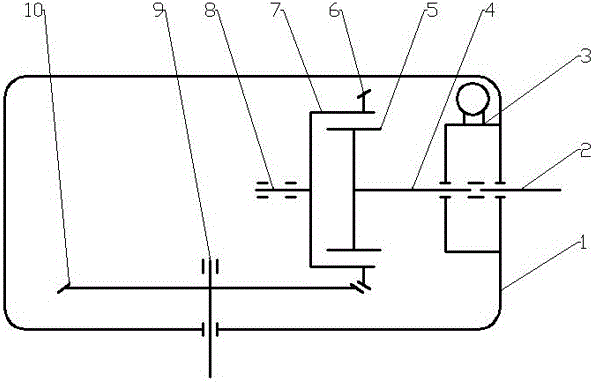

[0031] Such as figure 1 Shown: a permanent magnet continuously variable speed reducer, including a box body 1, a regulator 3 fixedly installed on the box body 1, and an input shaft 2, an adjustment shaft 4, a transmission shaft 8 and movably supported on the box body 1 The output shaft 9, the regulator 3 and the adjustment shaft 4 constitute the adjustment mechanism. The input shaft 2 is installed horizontally on the box body 1. The end of the input shaft 2 is sleeved with the adjustment shaft 4. The other end of the adjustment shaft 4 is connected to the cylindrical The permanent magnet rotor 5 is connected and the permanent magnet rotor 5, the adjustment shaft 4 and the input shaft 2 rotate synchronously. Specifically, the adjustment shaft 4 is sleeved on the input shaft 2 through a spline, so that the permanent magnet rotor 5 and the adjustment shaft 4 are in the position of the regulator. 3 slides left and right along the axial direction of the input shaft 2; the correspon...

Embodiment 2

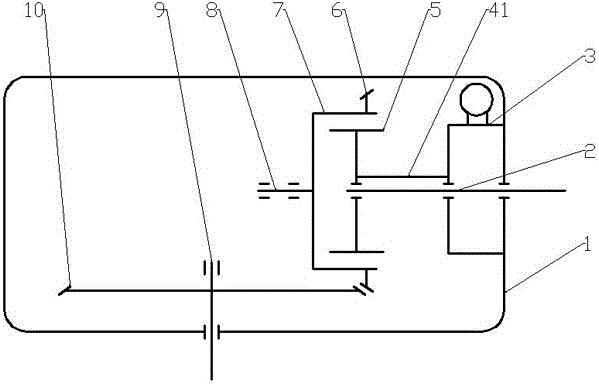

[0033] Such as figure 2Shown: a permanent magnet continuously variable speed reducer, including a box body 1, a regulator 3 fixedly installed on the box body 1, and an input shaft 2, a transmission shaft 8 and an output shaft 9 movably supported on the box body 1, The regulator 3 and the adjusting rod 41 form an adjusting mechanism, the input shaft 2 is installed horizontally on the box body 1, and the end of the input shaft 2 is provided with a permanent magnet rotor 5 which rotates together with it, and the permanent magnet rotor 5 is directly connected to one end of the adjusting rod 41. The other end of the adjustment rod 41 is connected to the regulator 3, and the permanent magnet rotor 5 is installed on the input shaft 2 through a spline, so that the permanent magnet rotor 5 and the input shaft 2 rotate together. Under the action, it slides left and right along the axial direction of the input shaft 2; the corresponding part of the permanent magnet rotor 5 is provided w...

Embodiment 3

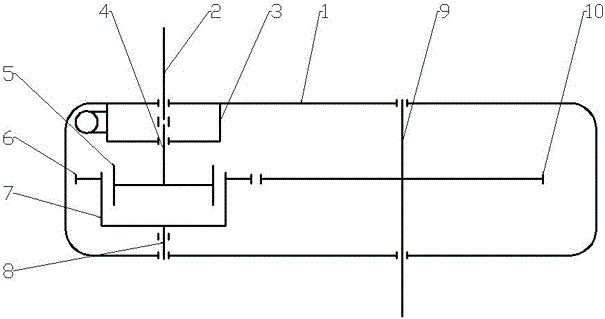

[0035] Such as image 3 Shown: a permanent magnet continuously variable speed reducer, including a box body 1, a regulator 3 fixedly installed on the box body 1, and an input shaft 2, an adjustment shaft 4, a transmission shaft 8 and movably supported on the box body 1 The output shaft 9, the regulator 3 and the adjustment shaft 4 constitute the adjustment mechanism, the input shaft 2 is vertically installed on the box body 1, and the lower end of the input shaft 2 is provided with the adjustment shaft 4 outside, and the lower end of the adjustment shaft 4 is connected with the cylindrical The permanent magnet rotor 5 is connected and the permanent magnet rotor 5, the adjustment shaft 4 and the input shaft 2 rotate synchronously. Specifically, the adjustment shaft 4 is sleeved on the input shaft 2 through a spline, so that the permanent magnet rotor 5 and the adjustment shaft 4 are in the position of the regulator. Under the action of 3, it slides up and down along the axial d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com